Using hold down/push blocks, Beveling and chamfering – Sears 149.23632 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

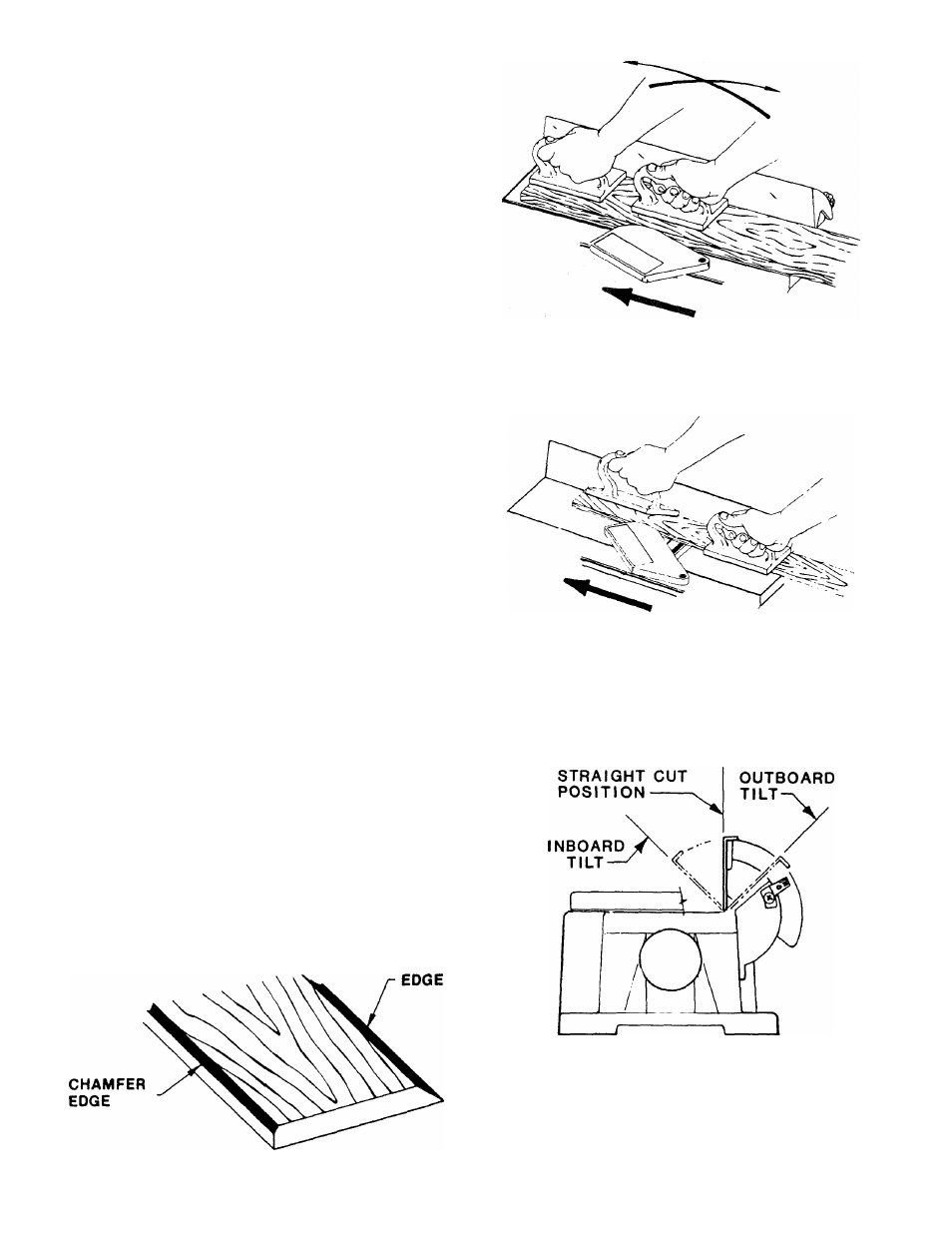

USING HOLD DOWN/PUSH BLOCKS

ALWAYS use the hold down/push blocks when JOINTING wood

that Is NARROWER than 3 In. or PLANING wood that Is THINNER

than 3 in.

Grasp the hold down/push blocks firmly with the fingers close

together and wrapped around the handle. Position them flat on

top of workpiece, and push the workpiece down against the

table to provide a quality cut and minimize the chance of a kick

back. -

Hold down pressure must be sufficient to prevent hoid down/

push biock from sliding or slipping on the surface of the work

piece when advancing work piece over cutter head.

Use a hand-over-hand motion of the hold down/push blocks

being carefui to maintain controi of the workpiece at ali times.

HAND-OVER HAND

This means that once the work piece has passed the cutter head

onto outfeed tabie, one hoid down/push biock must always

maintain contact with the work piece with outfeed tabie.

When pianing wood 3/4 in. thick and NARROWER than the hold

down/push block, tilt the hold down/push block so that it clears

the top of the cutter guard while feeding.

Never plane wood that is thinner than 1/2 in...because it is apt to

split or shatter and thus has a greater tendency to kickback.

A

CAUTION: IF THE HOLD DOWN/PUSH BLOCKS TEND TO

SLIP WHILE FEEDING, CLEAN RUBBER SURFACE

IMMEDIATELY WITH SANDPAPER.

BEVELING AND CHAMFERING

The fence on your jointer-planer is adjustable from 45° inboard

to 45° outboard. Adjust the fence to desired angie and tighten

iock knobs.

BEVELING is the cutting of. an angie on the entire edge of a

board. Beveling may require severai passes due to the depth of

cut needed to bevei entire edge of board.

BEVEL

CHAMFERiNG is removing only the corner of the edge of a

board. Normally a chamfer is made with one cut; therefore, a cut

deeper than 1/16" may be made.

11