Jnq instructions, A danger, Danger – Sears Craftsman 919.150270 User Manual

Page 6: Assembly instructions, Installation and startup procedures

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

/li U,, Li. LUUJ i.LvJli“

L/UV ILiJJiUU

%#l^l #"1WI

JNQ INSTRUCTIONS

HU, lOl^i r. i

Tools Needed for Unpacking

A Vz" socket wrwich.

Grasp the handle and lift the air compressor out of the

carton. Remove the styrofoam and plastic brace.

Note the plastic brace attached to the air compres

sor by a h©c screw. Using a

Vz

socket wrench, remove

№e hex screw. Discard both the screw and the plastic

brace.

Tools Needed for Assembly

A

Phillips screwdriver.

Installing rubber feet.

Enclosed with this compressor you will find three

screws, three rubber feet, three eyelets and two flat

washers. You will attech these to the bottom of the unit.

Refer to the air compressor diagram on page 10.

ASSEMBLY INSTRUCTIONS

1. Turn your compressor on its side.

2. Insert eyelet into rubber foot

3. Certter hole in rubber foot over flat washer and hole in

bottom of unit Insert screw and tighten. Note: Longer

screws and flat washers are to be used under front

two feet only. Shorter screw is to be used on back foot

only. Continue this process until all three feet are on

unit

INSTALLATION AND STARTUP PROCEDURES

Location of the Air Compressor

operate the air compressor in a dry, dean, cool and well

v^ilated area. The air intake muffler must

be

kept clear

of obstructions which could reduce air delivery of the air

compressor. The air compressor pump and case are

designed to allow tor proper cooling. Dean or blow off

dust or dirt that coltects on aJr compressor. A clean air

com^essor runs cooler and provides longer service.

Ttte ventilation openings on your air compressor are

necessary to maintain proper operating temperature.

Do not place rags or other containers on or near these

openings.

Extension Cords

Use extra ho^ instead of an extension cord to avoid

voltage drop and power loss to the motor.

if you

must

use an extension txjrd be sure it is:

• a 3-wire extension cord tiiat has a 3-biade grounding

plug, and a 3-slot receptacle that will accept the plug

on the compressor,

• in good coridition.

• 50 feet or shorter.

• 12 gauge (AWG) or larger. (Wire size increase as

gauge number decreases.) 10 AWG and 8 AWG,

may also be used. Do not use 14 or 16 AWG.

Grounding Instructions

W A R N I N G

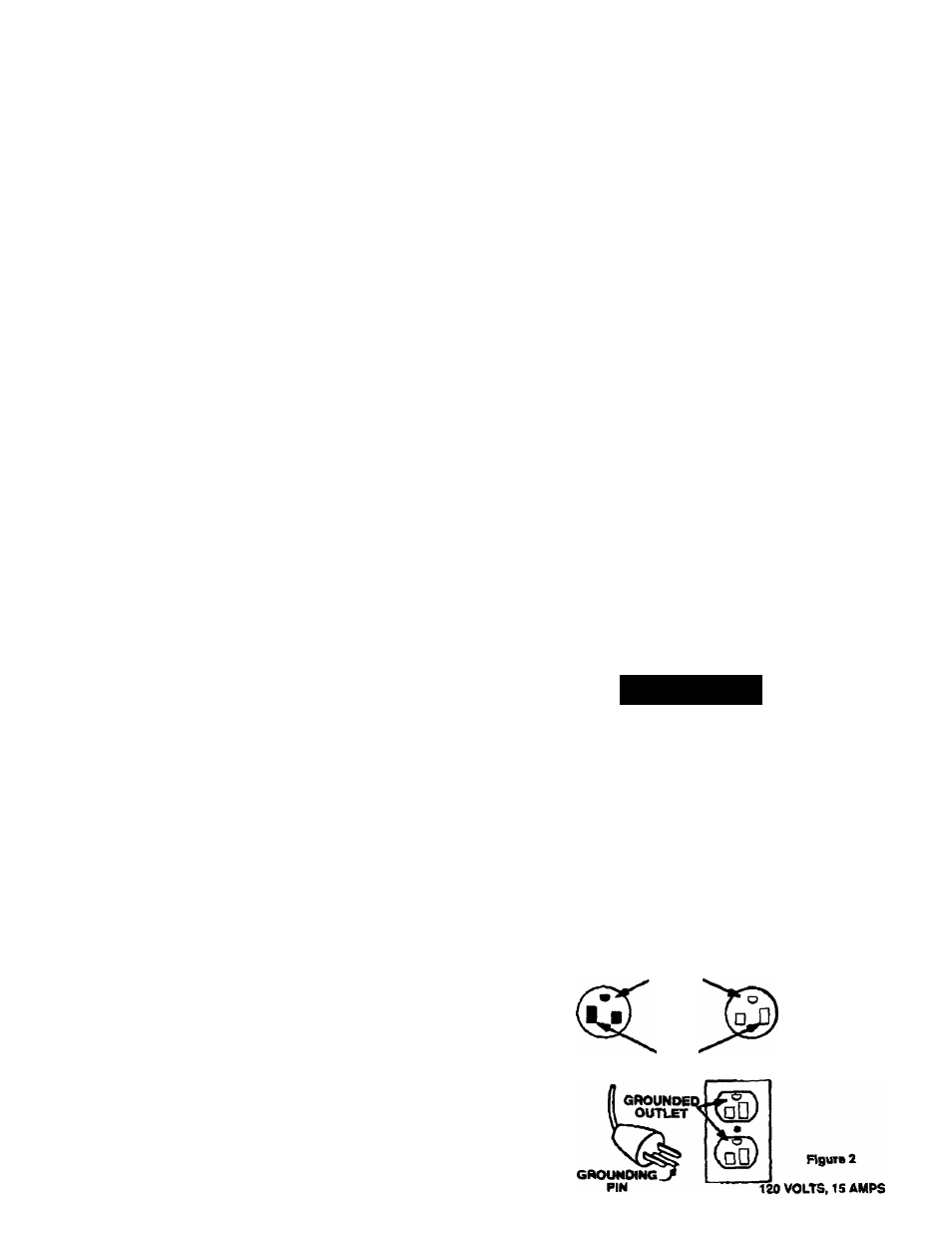

1. The air compressor is designed for 120 volt operation

only and is equipped with a cord hanring a grounding

wire with an appropriate grounding plug. The pltg

must be used with an outlet that has been installed

arto ground^ in accordance with ail local codes and

ordinances (see figure 2). The outlet must have the

same cxjnfiguration as the plug. DO NOT USE AN

ADAPTER.

2. Do not modify the plug that has been provided. If it

does not fit the avallabie outlet, toe correct outlet

should be installed by a qualified etoctrtcian.

3. Before eatto use, ir^pect toe plug and cord. Do not

use if there are signs of damage.

A

DANGER

RISK OF ELECTRICAL SHOCK. IF REPAIR

ING OR REPLACING CORD OR PLUG, THE

GROUNDING WIRE MUST BE KEPT SEPA

RATE

FROM

THE

CURRENT

CARRYING

WIRES. NEVER CONNECT THE GROUND

ING WIRE TO A FLAT BLADE PLUG TER

MINAL.

(THE

GROUNDING

WIRE

HAS

EITHER

GREEN

INSULATION

OR

GREEN

INSULATION WITH A YELLOW STRIPE).

If these grounding irrstojctions are mX completely under

stood, or if in doubt as to wtoetoer tfto comrxessor is

properly grounded, have the installation dtedred by a

qualified electridan.

IMPROPER GROUNDING CAN RESULT IN A

RISK

OF

ELECTRICAL

SHOCK.

IN

THE

EVENT OF A SHORT CIRCUIT, GROUNDING

REDUCES THE RISK OF SHOCK BY PRO

VIDING AN ESCAPE WIRE FOR THE ELEC

TRIC

CURRENT

THIS

AIR

COMPRESSOR

MUST BE PROPERLY GROUNDED. BEAD

THE FOLLOWING.

Plug

Qraund

WMto

'Win

Outlet

6