To stop engine, How to use your chipper-shredoer – Sears Craftman 247.79585 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TO STOP ENGINE

• Move throttle control lever to STOP position. See

figure 6.

• Disconnect spark plug \wire and move away from

spark plug to prevent accidental starting while

equipment is unattended. See figure 6.

HOW TO USE YOUR CHIPPER-SHREDOER

Do not attempt to shred or chip any material other

than vegetation found in a normal yard (i.e., branches,

leaves, twigs, etc.).

A

WARNING: THE CHIPPER-SHREDDER

DISCHARGES MATERIALS WITH CON

SIDERABLE VELOCITY. KEEP AWAY

FROM THE AREA AROUND THE CHUTE

DEFLECTOR.

ALWAYS

STOP

THE

ENGINE AND DISCONNECT THE SPARK

PLUG WIRE WHEN REMOVING OR

ATTACHING THE BAG WHEN CHANGING

CONTAINERS OR WHEN REMOVING THE

SHREDDED MATERIAL. WEAR SAFETY

GLASSES AND GLOVES WHENEVER

USING YOUR CHIPPER-SHREDDER.

The chipper-shredder is designed for three different

methods of operation.

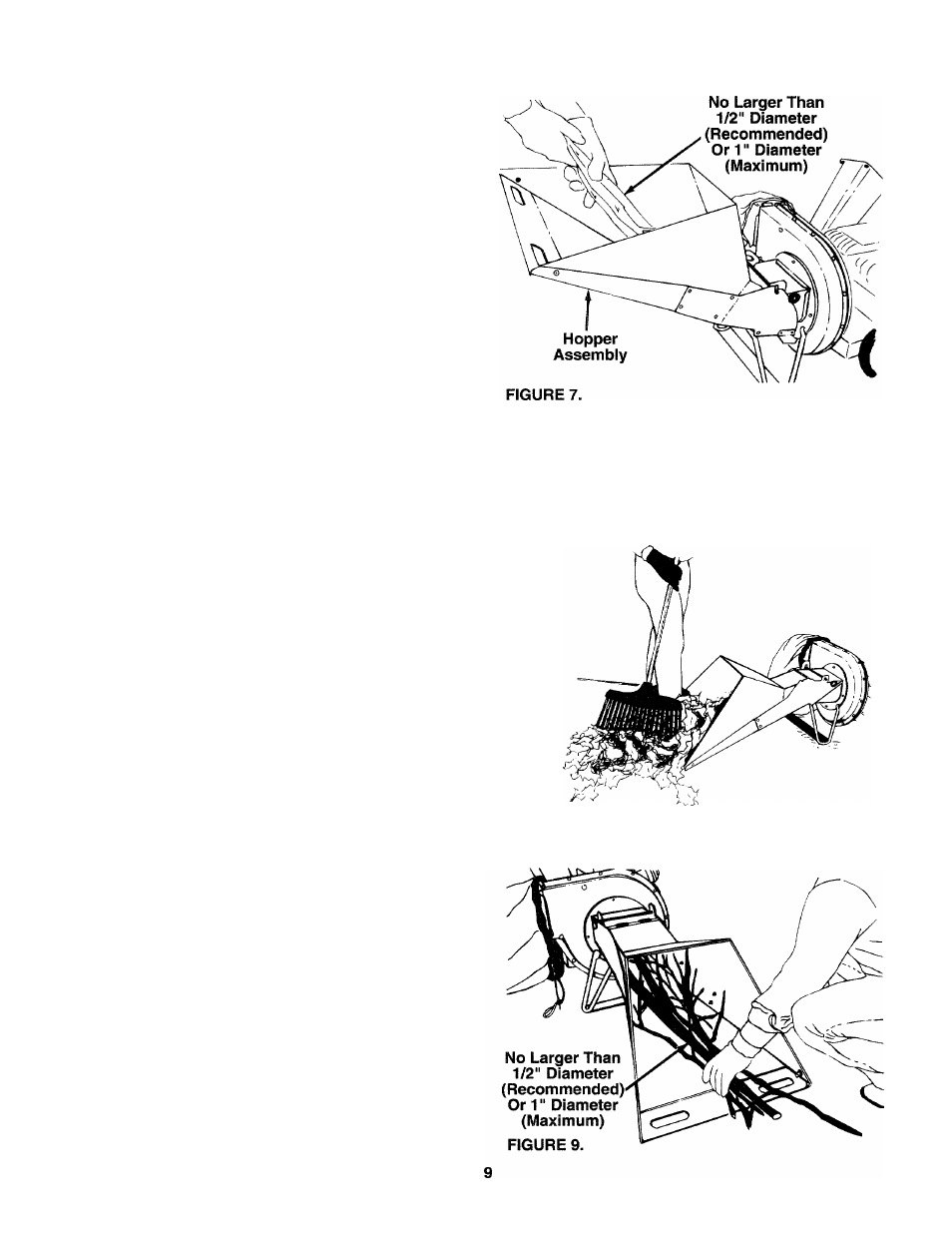

• Leaves and small branches up to 1/2" diameter

(recommended) or 1" diameter (maximum) can be

fed into the hopper assembly when it is in the

raised position. See figure 7. If it becomes neces

sary to push material into the chipper-shredder,

use a small diameter stick—NOT YOUR HANDS.

The stick should be small enough that it will be

ground up if gets into the impeller assembly.

A

WARNING: DO NOT PUT MATERIAL

LARGER THAN 1/2" IN DIAMETER (REC

OMMENDED) or 1" DIAMETER (MAXI

MUM) INTO THE HOPPER ASSEMBLY.

MATERIAL UP TO A MAXIMUM OF 3" IN

DIAMETER MAY BE FED INTO THE

CHIPPER CHUTE. DO NOT ATTEMPT TO

SHRED OR CHIP ANY MATERIAL LARG

ER THAN 3" IN DIAMETER. PERSONAL

INJURY OR DAMAGE TO THE MACHINE

COULD RESULT.

Leaves and small twigs can be raked into the hop

per assembly when the hopper assembly is low

ered to the ground. See figure 8. Small branches

up to 1/2" diameter (recommended) or 1" diam

eter (maximum)

can also be fed into the hopper

assembly in this position. See figure 9.

FIGURE 8.