Service – Carrier 38AK007 User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Unit Preparation

— Make sure that unit has been in

stalled in accordance with installation instructions and ap

plicable codes.

Compressor Mounting

— Compressors are inter

nally spring mounted. Do not loosen or remove compressor

holddown bolts.

Internal Wiring

— Check all electrical connections in

unit control boxes; tighten as required.

Time Guard II® Device

— Time Guard II Circuit pro

vides for a delay of approximately 5 minutes before restart

ing compressor after shutdown from safety device action.

On start-up, the Time Guard timer causes a delay of ap

proximately 15 seconds after thermostat closes.

Refrigerant Service Ports

— Each unit system may

have Schrader type service ports: one on the suction line,

one on the liquid line, and one on the compressor discharge

line. Be sure that caps on the ports are tight.

Cooling

— Set space thermostat to OFF position. Set sys

tem selector switch at COOL position and fan switch at AUTO,

position. Adjust thermostat to a setting below room tem

perature. Compressor starts on closure of contactor.

Check cooling effects at a setting below room tempera

ture. Check unit charge. Refer to Refrigerant Charge sec

tion on page 5.

Reset thermostat at a position above room temperature.

Compressor will shut off.

TO SHUT OFF UNIT - Set system selector switch at OFF

position. Resetting thermostat at a position above room tem

perature shuts unit off temporarily until space temperature

exceeds thermostat setting. Units are equipped with Cycle-

LOC™ protection device. Unit shuts down on any safety

trip and remains off; an indicator light on thermostat comes

on. Check reason for safety trip.

Compressor restart is accomplished by manual reset at

the thermostat by turning the selector switch to OFF posi

tion and then to ON position.

Sequence of Operation

— At start-up, the thermo

stat calls for cooling, and with all safety devices satisfied,

the compressor contactor and fan contactor will energize,

causing the compressor and outdoor-fan motor to operate.

Contacts on TBl terminals 1 and 2 are also energized, al

lowing the field supplied and installed indoor-fan contactor

to function. A field supplied and installed liquid line valve

(connect to TB1 terminals 3 and 4) will also open, allowing

the system to function in cooling. As cooling demand is

satisfied, the thermostat contacts break, deenergizing the

contactor causing the system to shut off. The liquid line

shutoff valve closes minimizing the potential for refrigerant

migration at this time. The compressor does not restart un

til the thermostat again calls for cooling. If a demand for

cooling occurs within 5 minutes after the thermostat is sat

isfied, the system will not restart due to the feature of Time

Guard®II. After the 5 minute time period, the system will

restart as normal upon thermostat demand. The system is

protected with Cycle-Loc device so that the compressor will

not start if a high-pressure or low-pressure fault occurs. Merely

turn down the thermostat to eliminate the cooling demand

to reset the Cycle-Loc device. This should be done only

once, and if system shuts down due to the same fault, de

termine the problem before attempting to reset the Cycle-

Loc device. The 38AK007 unit does not require a crank

case heater.

SERVICE

A CAUTION

When servicing unit, shut off all electrical power to

unit to avoid shock hazard or injury from rotating parts.

Cleaning

— Inspect unit interior at the beginning of each

cooling season and as operating conditions require.

CONDENSER COIL — Inspect coil monthly. Clean con

denser coil annually and as required by location or outdoor-

air conditions.

Clean coil as follows:

1. Turn off unit power.

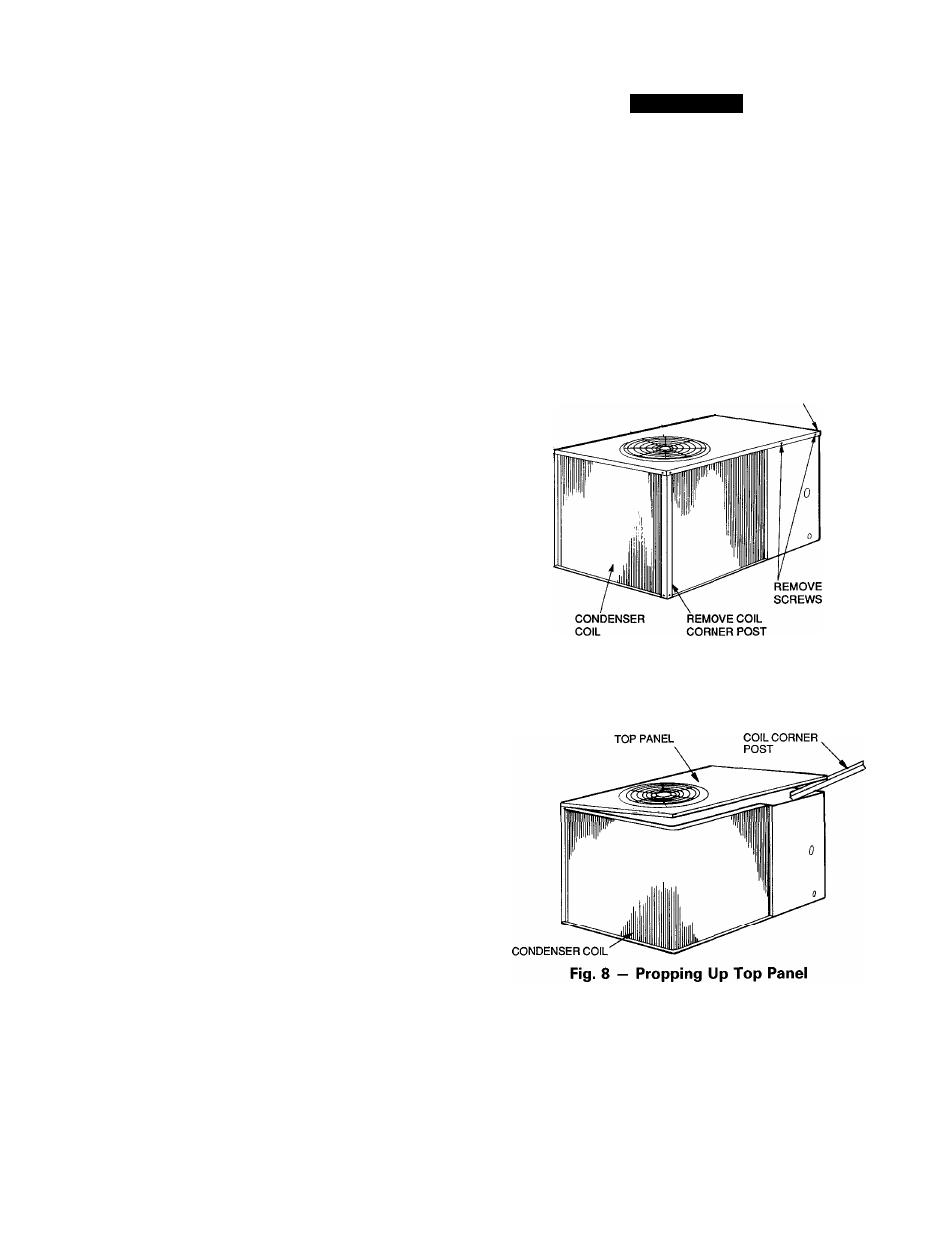

2. Remove top panel screws on condensing unit.

3. Remove condenser coil comer post. See Fig. 7. To hold

top panel open, place coil comer post between top panel

and side panel. See Fig. 8.

CONTROL BOX

CORNER POST

Fig. 7 — Cleaning Condenser Coil