Start-up preliminary checks, Fig. 6 — cooling charging chart — 38ak007, Leak test – Carrier 38AK007 User Manual

Page 5: Evacuate and dehydrate, Refrigerant charge, Chart, Outdoor, Must, Operatin, Liquid

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

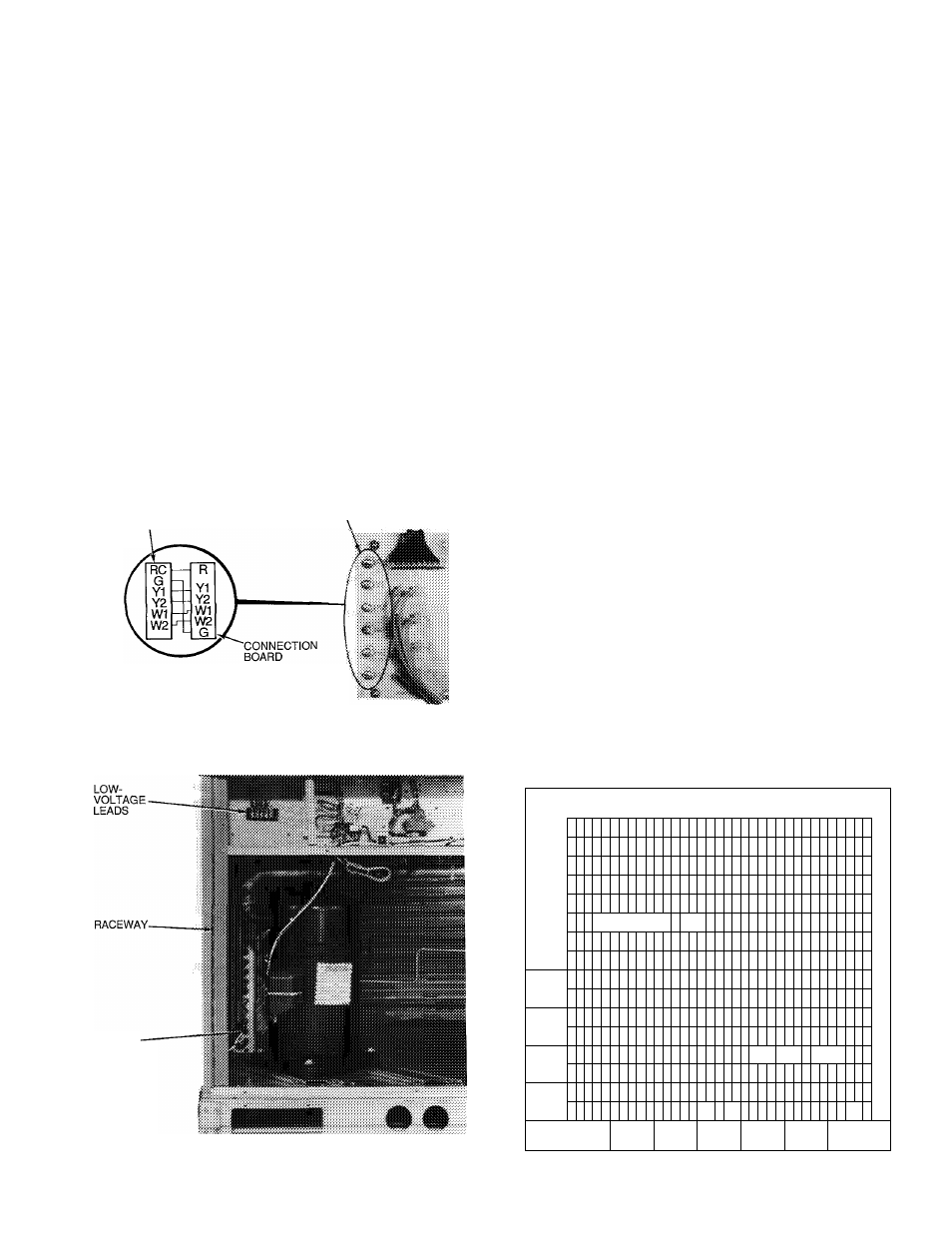

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation in

structions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense

average temperature in accordance with thermostat instal

lation instructions.

Route thermostat cable or equivalent single leads of col

ored wire from subbase terminals to low-voltage connec

tions on unit (shown in Fig. 4) as described in Steps 1 through

3 below.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (Amer

ican Wire Gage) insulated wire (35 C minimum). For 50 to

75 ft, use no. 16 AWG insulated wire (35 C minimum).

For over 75 ft, use no. 14 AWG insulated wire (35 C min

imum). All wire larger than no. 18 AWG cannot be directly

connected to the thermostat and will require a junction box

and splice at the thermostat.

1. Connect thermostat wires to screw terminals of low-

voltage connection board.

2. Pass the control wires through the hole provided in the

comer post.

3. Feed wire through the raceway built into the comer post

to the 24-v barrier located on the left side of the control

box. See Fig. 5. The raceway provides the UL required

clearance

wiring.

THERMOSTAT

between the high- and low-voltage

THERMOSTAT

CONNECTIONS

FOR STANDARD UNIT

WIRING CONNECTIONS

UNIT CONNECTION

BOARD

Fig. 4 — Control Wiring Connections

HOLE IN

END PANEL

(HIDDEN)

START-UP

Preliminary Checks

1. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

2. Field electrical power source must agree with unit name

plate rating.

3. All service valves must be open.

Leak Test

— Test entire refrigerant system by using soap

bubbles and/or an electronic leak detector.

Evacuate and Dehydrate

— Evacuate and dehy

drate entire refrigerant system by use of the methods de

scribed in GTAC II, Module 4, System Dehydration.

Refrigerant Charge

— Refer to GTAC II, Module 5,

Charging Recovery, Recycling and Reclamation.

Unit panels must be in place when unit is operating dur

ing charging procedure.

Unit is shipped with holding charge only. Weigh in 7 lbs

R-22 to start unit.

NO CHARGE — Use standard evacuating techniques. Af

ter evacuating system, weigh in the specified amount of re

frigerant. (Refer to Table 1.)

LOW CHARGE COOLING - Use Cooling Charging Chart,

Fig. 6. Vary refrigerant until the conditions of the chart are

met. Note the charging chart is different from type nor

mally used. Chart is based on charging the units to the cor

rect subcooling for the various operating conditions. Accu

rate pressure gage and temperature sensing device are required.

Connect the pressure gage to the service port on the liquid

line service valve. Mount the temperature sensing device

on the liquid line, close to the liquid line service valve and

insulate it so that outdoor ambient temperature does not af

fect the reading. Indoor-air cfm must be within the normal

operating range of the unit.

Operate unit and adjust charge to conform with charging

chart, using liquid pressure and temperature to read chart.

TO USE COOLING CHARGING CHART - Initially charge

with 7 lbs. R-22. Place pressure gage at liquid line service

valve. Install thermocouple to liquid line near the liquid line

service valve. Operate unit. Plot liquid pressure and tem

perature on chart and add or reduce charge to meet curve.

Fig. 5 - Field Control Wiring Raceway

CHARGING

CHART

- 38

AK

007

OUTDOOR

FAN

MUST

BE

OPERATIN

0

Q

.

/

g

uj

>

Q

1

AC

Ì

»

1

F AG5^ :

UR№

<

p

< 90-

tt

UJ

1

i

/

7

2

5

o

2

2

/

/

« XX£

:

h

UMe

IF

«

.i

U

ave

/

Ì

s

h

0 r

UOUiO

0

2

PRESSURE

0 25

LIQUID

0

31

VALVE (PS

0 3!

IG

)

i

0 400

Fig. 6 — Cooling Charging Chart — 38AK007