Refrigerant piping sizes, Step 2 - rig and mount the unit, Step 4 — make electrical connections – Carrier 38AK007 User Manual

Page 2: Ik cautlon, A warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

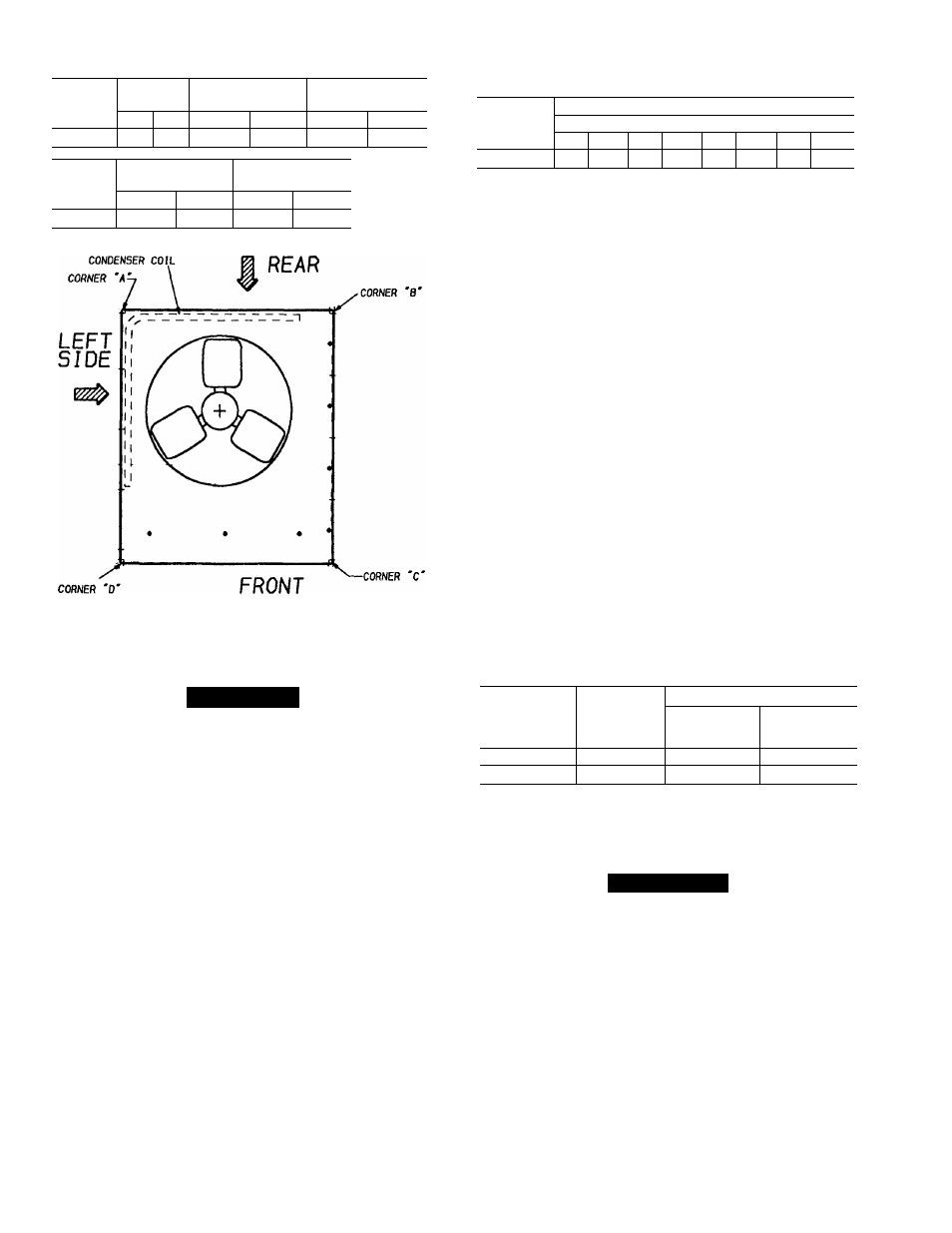

Table 2 — Weight Distribution

REFRIGERANT PIPING SIZES

UNIT

STD. UNIT

WEIGHT

CORNER WEIGHT

(A)

CORNER WEIGHT

(B)

lbs.

kg.

lbs.

kg.

lbs.

kg.

38AK007

340

154

86

39

53

24

UNIT

CORNER WEIGHT

(C)

CORNER WEIGHT

(D)

lbs.

kg.

lbs.

kg.

38AK007

77

35

124

56

Step 2 - Rig and Mount the Unit

ik

CAUtlON

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rig

ging. Refer to rigging label for preferred rigging method.

Spreader bars are not required if top crating is left on unit.

All panels must be in place when rigging. (See Fig. 2) As

further protection for coil faces, plywood sheets may be

placed against sides of unit, behind cables. Run cables to a

central suspension point so that angle from the horizontal is

not less than 45 degrees. Raise and set unit down carefully.

If it is necessary to roll unit into position, mount unit on

rails, using a minimum of 3 rollers.

Apply force to rails,

not unit. If unit is to be skidded into position, place it on a

large pad and drag it by the pad.

Do not apply any force to

unit.

Raise from above to lift unit from rails or pad when unit

is in final position.

After unit is in position, remove all shipping wrapping

and top crating.

Step 3 — Complete Refrigerant Piping Connec

tions

— Suction connection is 1-1/8-in. sweat with plas

tic cap; liquid connection is 1/2-in. sweat with plastic cap.

Follow standard piping practices.

EQUIVALENT LENGTH OF PIPING - FT

COND

UNIT

0-25

26-50

51-75

76-100

Line Size (in. OD)

L

s

L

s

L

s

L

s

38AK007

V2

IVs

V2

IVa

Va

IVe

V2

IVs

L

— Liquid Line

S

— Suction Line

NOTES:

1. Pipe sizes are based on a 2° F loss for liquid and suction lines

2. Pipe sizes are based on an equivalent length equal to the max

imum length of interconnecting piping plus 50 percent for fittings.

3. Charge units with R-22 in accordance with unit installation

instructions.

SIZE REFRIGERANT LINES - Consider length of pip

ing required between condensing unit and evaporator, amount

of liquid lift, and compressor oil return. See Table 3 and

also refer to Part 3 of Carrier System Design Manual for

design details and line sizing. Refer to evaporator installa

tion instructions for additional information.

INSTALL FILTER DRIER AND MOISTURE INDICA

TOR — The filter drier is factory supplied and field in

stalled. Moisture indicator is a field-installed option and should

be installed just after liquid line shutoff valve.

Do not use a

receiver; there is none provided with unit and one should

not be used.

NOTE: Unit is shipped with R-22 holding charge. System

pressure must be relieved before removing caps.

Pass nitrogen or other inert gas through piping while braz

ing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve to evap

orator section. It is recommended that a field supplied liq

uid line solenoid be positioned in the main liquid line close

to the evaporator coil, and wired to close when compressor

stops to minimize refrigerant migration during the “OFF”

cycle.

Table 3 — Liquid Line Data

UNIT 38AK007

MAX

ALLOWABLE

LIQUID

LIFT (ft)

LIQUID LINE

Max Allowable

Pressure Drop

(psi)

Max Allowable

Temp Loss

(F)

60 Hz

86

7

2

50 Hz

72

7

2

NOTE: Values shown are for units operating at 45 F saturated suc

tion and 95 F entering air

Step 4 — Make Electrical Connections

A WARNING

Unit cabinet must have an uninterrupted, unbroken elec

trical ground to minimize the possibility of personal in

jury if an electrical fault should occur. This ground may

consist of electrical wire connected to unit ground lug

in control compartment, or conduit approved for elec

trical ground when installed in accordance with NEC

ANSI (American National Standards Institute)/NFPA

(National Fire Protection Association) 70-1987 and lo

cal electrical codes. Failure to follow this warning could

result in the installer being liable for personal injury of

others.