A warning, Ik caution, Fig. 7—typical circuit connections – Carrier 38QRA User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

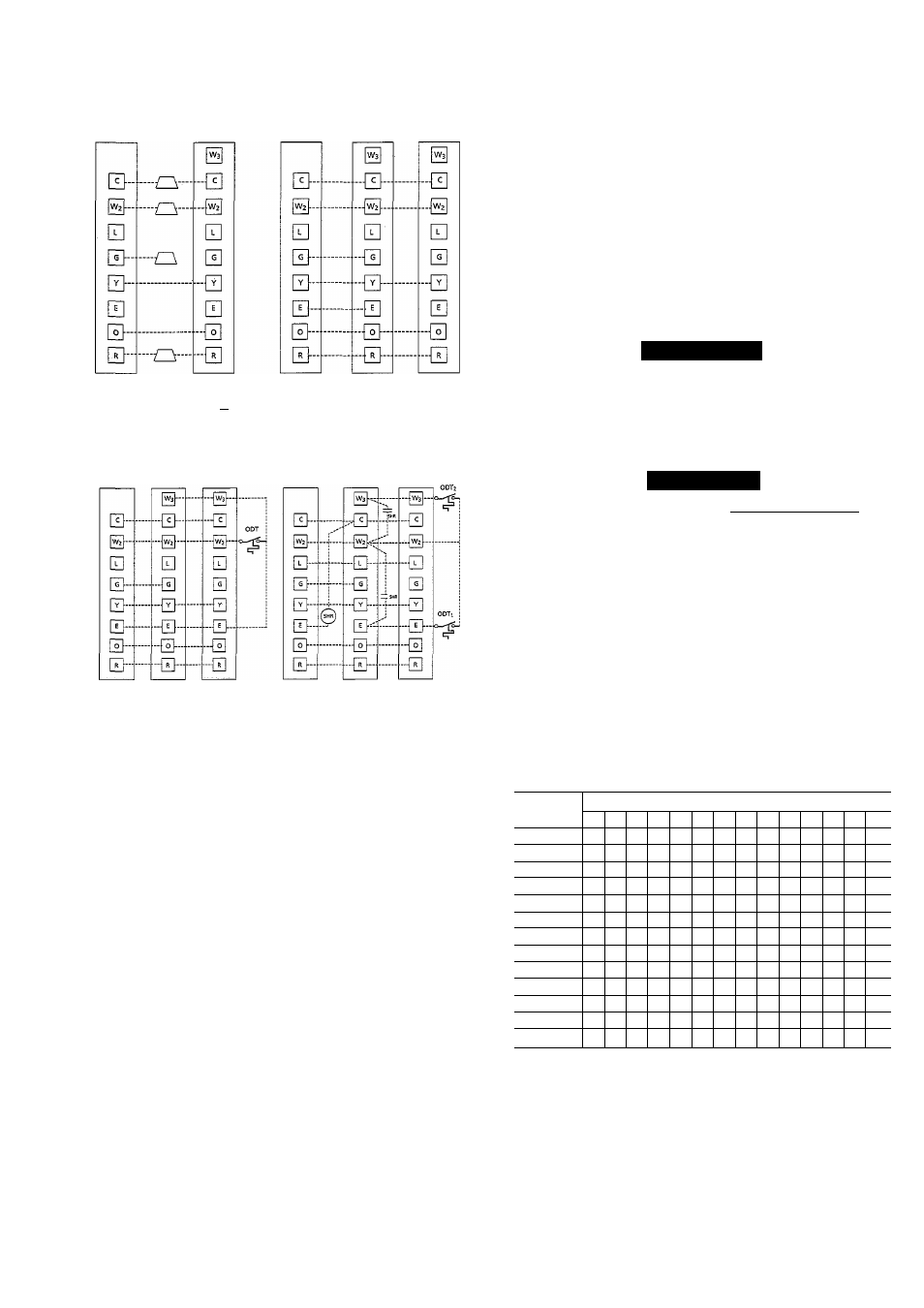

SYSTEMS WITHOUT OUTDOOR THERMOSTATS

Thermostat Indoor

Outdoor

Subbase

^

. ,

Splice

Terminal

Connection Board

Thermostat

Subbase

Terminal

Board

Terminal

Board

D VWTH FF1A, 40nc FAN COIL

USED WITH FD3A, FB4A. FB5A. FK4A,

40AQ, 40DQ, 40QBAÎH OR 40YAWYZ

!

V FIELO SPLICE

SYSTEMS WITH ONE OUTDOOR THERMOSTAT

Thermostat

Indoor

Subbase

Terminal

Board

A88285

SYSTEMS WITH TWO OUTDOOR THERMOSTATS

USED WITH {?1A. 4QRC FAN COIL

- FACTOflVVVIRlNG

■ FIEIOWIRING

OU'BOORTHERMOSTAT

SUPPIEUENTAI. HEAT RELAV

REMOVE FAaORYINSTAUEO JUMPERS ON INDOOR FAN COIL TERMINAL BOARD WHEN INSTALUNSOUTDOORTHERMOSTATS

Fig. 7—Typical Circuit Connections

A88286

Cooling

On a “call for cooling”, the thermostat “makes” circuits R- O,

R-Y and R-G. Circuit R-0 energizes the reversing valve, switching

it to cooling position. Circuit R-Y energizes the contactor, starting

outdoor fan motor and compressor circuit. R-G energizes the

indoor unit blower relay, starting the indoor blower motor on high

speed.

When the thermostat is satisfied, its contacts open, de-energizing

the contactor and blower relay. Compressor and motors should

stop.

Heating

On a “call for heating”, the thermostat “makes’ ’ circuits R- Y and

R-G. Circuit R-Y energizes contactor, starting outdoor fan motor

and compressor. Circuit R-G energizes the indoor blower relay,

starting the blower motor on high speed.

Should the temperature continue to fall, R-W2 is made through the

second-stage room thermostat bulb. Circuit R-W2 energizes a

sequencer, bringing on the first bank of supplemental electric heat

and providing electrical potential to the second heater sequencer (if

used). If the outdoor temperature falls below the setting of the

outdoor thermostat, (field-installed operation) the contacts close to

complete the circuit and bring on the second bank of supplemental

electric heat.

When the thermostat is satisfied, its contacts open, de-energizing

the contactor and sequencer. All heaters and motors should stop.

Defrost

The defrost control is a time/temperature control which includes a

field-selectable time period between defrost cycles (30, 50 and 90

minutes, factory set at 90 minutes). Quick connects are located at

board edge.

The electronic timer and the defrost cycle will start only when the

contactor is energized, defrost thermostat is closed and the timing

device has completed one cycle.

The defrost mode is identical to the cooling mode except that the

outdoor fan motor stops and second stage heat is turned on to

continue warming the conditioned space.

A WARNING

Service valve gage ports are not equipped with Schrader

valves. To prevent personal injury, make sure gage manifold

is connected to the valve gage ports before moving valves off

fully back seated position. Wear safety glasses and gloves

when handling refrigerant.

ik CAUTION

Compressor damage may occur if system is overcharged. |

Step 9—Refrigerant Charging

NOTE: See Table 2 for correct system charge of tested combi

nation.

Cooling

To check and adjust charge during cooling season, use Tables 4

and 5 and the following procedure:

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suction valve

service port.

Table 4—Superheat Charging Table

(Superheat Entering Suction Service Valve)

OUTDOOR

INDOOR COIL ENTERING AIR (F) WB

TEMP

50

52

54

56

58

60

62

64

66

68

70

72

74

76

55

9

12

14

17

20

23

26

29

32

35

37

40

42

45

60

7

10

12

15

18

21

24

27

30

33

35

38

40

43

65

—

6

10

13

16

19

21

24

27

30

33

36

38

41

70

_

7

10

13

16

19

21

24

27

30

33

36

39

75

—

—

6

9

12

15

18

21

24

28

31

34

37

80

—

—

—

—

5

8

12

15

18

21

25

28

31

35

85

8

11

15

19

22

26

30

33

90

5

9

13

16

20

24

27

31

95

6

10

14

18

22

25

29

100

8

12

15

20

23

27

105

5

9

13

17

22

26

110

6

11

15

20

25

115

8

14

18

23

—Do not attempt to charge system under these conditions or refrigerant

slugging may occur.

3. Measure suction line temperature by attaching a service

thermometer to unit suction line near suction valve. Insulate

thermometer for accurate readings.

4. Measure outdoor coil inlet air dry-bulb temperature with a

second thermometer.

5. Measure indoor coil inlet air wet-bulb temperature with a sling

psychrometer.