Fig. 3—unit rating piate, A caution, Imax■ fu5e/hasr tyre'';cb; ahpt pi 5 t 0 n – Carrier 38QRA User Manual

Page 3: 7i per i, Chw v made in mexico

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A CAUTION

DO NOT BURY MORE THAN 36 IN. (914mm) OF RE

FRIGERANT TUBING IN GROUND. If any section of

tubing is buried, there must be a 6-in.(152mm) vertical rise to

the valve connections on the outdoor unit. If more than the

recommended length is buried, refrigerant may migrate to

cooler buried section during extended periods of unit shut

down, causing refrigerant slugging and possible compressor

damage at start-up.

Step 5—Make Piping Connections

Outdoor units may be connected to indoor sections using accessory

tubing package or field-supplied tubing of refrigerant grade,

correct size, and condition. The liquid- and vapor-tube diameters

can be determined by using Table 3. For tubing requirements

beyond 50 ft (15.24m), obtain information from your local

distributor.

If either refrigerant tubing or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 1000

microns to eliminate contamination and moisture in the system.

Run refrigerant tubes as directly as possible, avoiding unnecessary

turns and bends. Suspend refrigerant tubes so they do not damage

insulation on vapor tube and do not transmit vibration to the

structure. Also, when passing refrigerant tubes through the wall,

seal opening so vibration is not transmitted to stmcture. Leave

some slack in refrigerant tubes between structure and unit to

absorb vibration.

OUTDOOR UNIT CONNECTED TO FACTORY APPROVED

INDOOR UNIT — Outdoor unit contains holding refrigerant

charge only. See Table 2 for correct system charge when con

nected by 25 ft (7.62m) of field-supplied or factory accessory

tubing. Add charge as required to achieve correct total. For long

line application information, contact your local distributor.

Table 2—Refrigerant Charge

OUTDOOR

UNIT

PHASE

CHARGE (LB)

018

1

4.25

024

1

4.75

030

1

6.00

036

1

7.00

036

3

11.63

048

1 &3

9.44

060

1 &3

11.75

Table 3—Refrigerant Connections and Recom

mended Liquid and Vapor Tube Diameters (In.)

UNIT

SIZE

LIQUID

VAPOR

Connect

Dia

Tube

Dia

Connect

Dia

Tube

Dia

018,024,030

3/8

3/8

5/8

5/8

036

3/8

3/8

3/4

3/4

048

3/8

3/8

7/8

7/8

060

3/8

3/8

7/8

1-1/8

Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50

ft, consult Long-Line Application Guideline.

REFRIGERANT TUBING — Connect tubing to fittings on out

door unit vapor and liquid service valves. (See Fig. 2.) Remove

brass piston retainer. Insert outdoor piston shipped in bag with

indoor piston in the liquid service valve, replace brass piston

retainer and connect sweat adapter provided. (See Fig. 5.)

CARRIER CORP.

IN 46206

MODEL N0.

SERIAL N0.

1 DF.SIGN/TEST PRESSURE GAGE 1

HIGH PSI

300 kPa 2068

TSEZ'PSl

150 TPo 1034

COMPRESSOR

FAN MOTOR

powgPi S

upply

VOLTS AC

VOLTAGE RAN5F

MIN

¿I

SYSTEM

VOLTS

EHÜI

£LA

SUITABLE FOR

OUTDOOR USE

REFRIGERANT:

R-22

LBS kg

HOLDING CHARGE

MAX

MIN

IMAX■ FU5E/HASR TyRE'';CB; AHPT

PI5T0N

nn

OP

P

hi

I

h

7I

PER I

nstallation

I

n

SFR

u

CHW

V MADE IN MEXICO

CERTIFICATION APPLIES QH.Y

IKN THE CO(f>LETE SYSTD1

IS LISTED WITH ARI

I

317204-401 REV.

Fig. 3—Unit Rating Piate

A90282

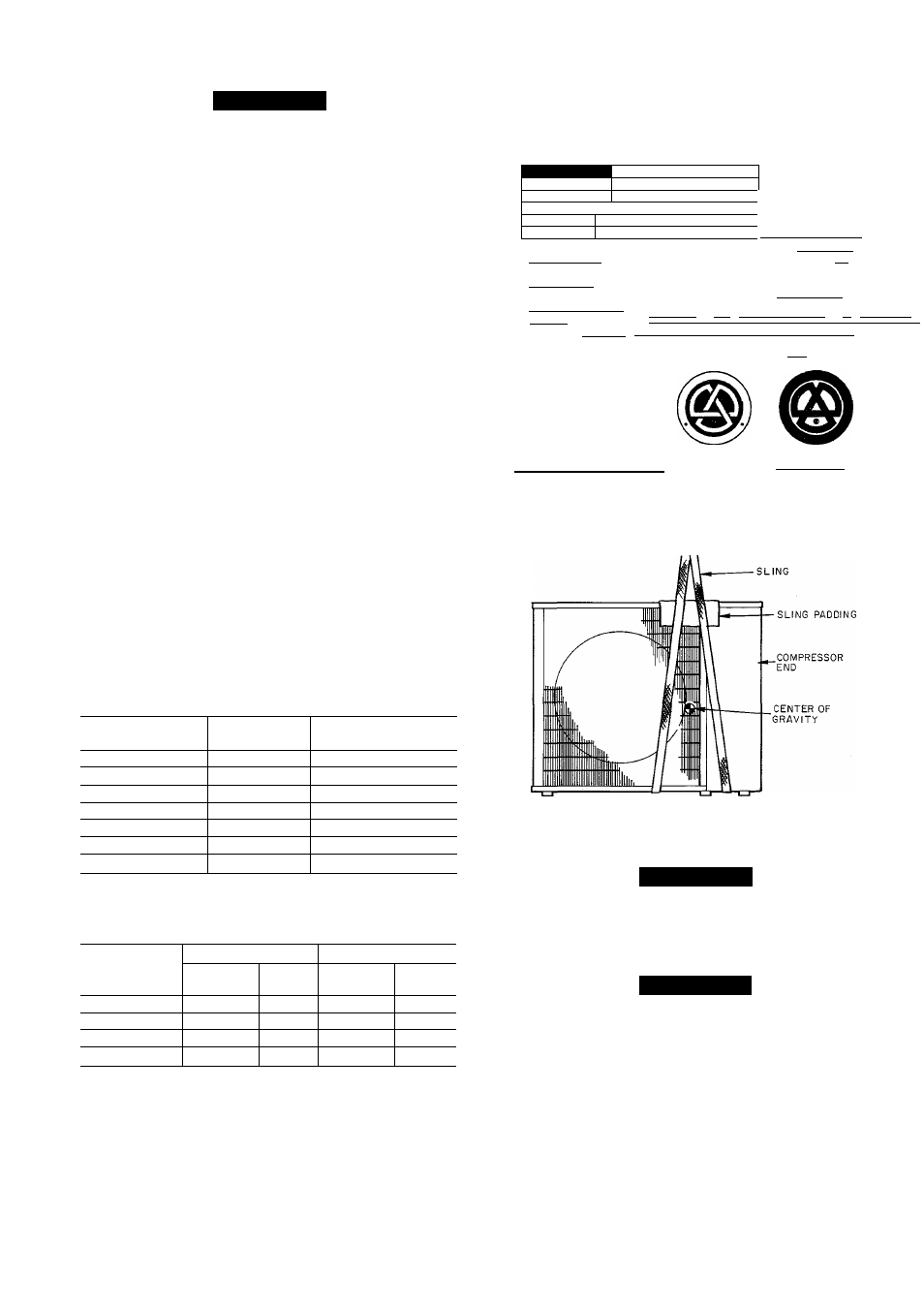

Fig. 4—Rigging

A CAUTION

A90285

A brazing shield MUST be used when tubing sets ate being

brazed to the service valves to prevent damage to the painted

unit surface.

A CAUTION

To avoid valve damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet cloth.

FILTER DRIER — Install in field liquid line, if used.

SWEAT CONNECTION — Use refrigerant grade tubing. Service

valves are closed from factory and ready for brazing. After

wrapping the service valve with a wet cloth, the tubing set can be

brazed to the service valve using either silver bearing or non-silver

bearing brazing material. Consult local code requirements. Refrig

erant tubing and indoor coil are now ready for leak testing. This

check should include all field and factory joints.