Fig. 10—venting boiler into masonry chimney – Carrier 61SW User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

If boiler is installed with single wall vent, it must have a 6-in.

clearance between its surface and any combustible material. A new

Type-Bl vent pipe or flexible liner must be installed in accordance

with the instructions furnished with the vent.

Check the vent pipe to see if it is firestopped where it goes through

the floor or ceiling. It should have an approved vent cap with

clearances from the roof as shown in Fig. 9. If clearances are less

than shown in Fig. 9, have the vent checked by local authorities.

- LINER

- CHIMNEY

A92406

Fig. 10—Venting Boiler Into Masonry Chimney

For boilers connected to gas vents or chimneys, vent installations

shall be in accordance with Part 7, Venting of Equipment, of the

National Fuel Gas Code, ANSI Z223.1-latest issue and applicable

provisions of the local building codes.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

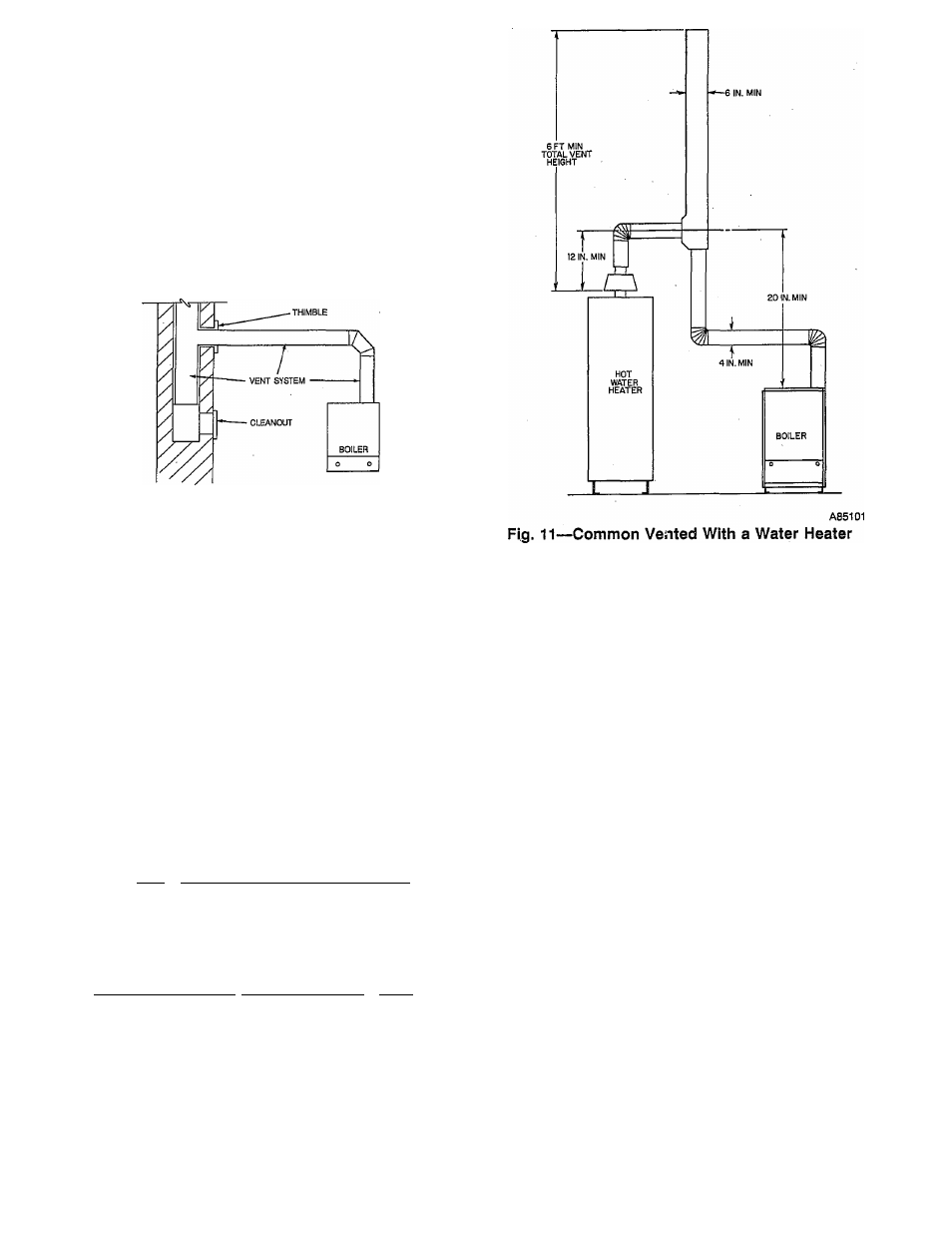

The induced-combustion boiler can be common vented with a

water heater. (See Fig. 11.)

REMOVAL OF EXISTING BOILER FROM COMMON VENT

SYSTEM

1. In replacement installations where an existing vent system

may be used, inspect the vent system for condition, size, type

of material, and height to meet the appliance application

requirements. If it is oversized, condensation could corrode

the venting system. Installation of a new venting system may

be required.

2. When removing an existing boiler from a venting system

serving other appliances, the vent system is likely to be too~

large to vent the remaining attached appliances properly.

The following steps shall be followed with each appliance

remaining, connected to the common venting system placed in

“operation

7

while-the"otherappliances-remaining-connected-to-

the common venting system are not in operation:

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, conosion and other deficiencies which

could cause an unsafe condition.

c. Insofar as is practical, close all building doors and windows

and all doors between spaces in which appliances remain

ing connected to the common venting are located and other

spaces of the building. Turn on clothes dryers and any

appliance not connected to the common venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum speed.

Do not operate a summer exhaust fan. Close fireplace

dampers.

d. Follow the lighting/operating instructions. Place the appli

ance being inspected in operation. Adjust thermostat so

appliance will operate continuously.

e. Test for spillage at the drafthood relief opening after 5

minutes of main burner operation using the flame of a

match or candle.

f. Mter it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any other gas-burning

appliance to their previous conditions of use.

g. If improper venting is observed during any of the above

tests, the common venting system must be corrected. The

vent system or vent connectors may need to be resized

----- according-to-these-instruetions-to-approaeh-the-minimum—

sizénñsiñgfKeTppWpfiáté^GAMA'Vehting Tables7Paft 7 bf~

the National Fuel Gas Code NFPA 54-1988/ANSI Z223.1-

1988.

-ELECTRICAL-

IMPORTANT:

Before proceeding with the electrical connections,

make certain the volts, hertz, and phase correspond to that

specified on the boiler rating plate.

-

The specific unit Installation Instructions contain wiring diagrams

which show the proper field high- and low-voltage wiring. Make

all connections in accordance with the National Electrical Code

and any loeal codes or ordinances that might apply.

The boiler, when installed, must be electrically grounded in

accordance with the National Electrical Code, ANSI/NFPA No.

70-1990.

A permanent, separately fused electrical power supply, complete

with manual disconnect switch, must be provided for this unit.