Fig. 5—fresh air duct for tightly sealed buildings – Carrier 61SW User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 3—Fresh Air Duct Capacities for Tightly

Sealed Houses*

FRESH AIR

DUCT SIZE

(IN.)

1/4-MESH

SCREEN

(BTUH)

WOOD

LOUVERS

(BTUH)

METAL

LOUVERS

(BTUH)

3 X 12

144,000

36,000

108,000

8x8

256,000

64,000

192,000

8

X

12

384,000

96,000

288,000

8-1/2

X

16

512,000

128,000

384,000

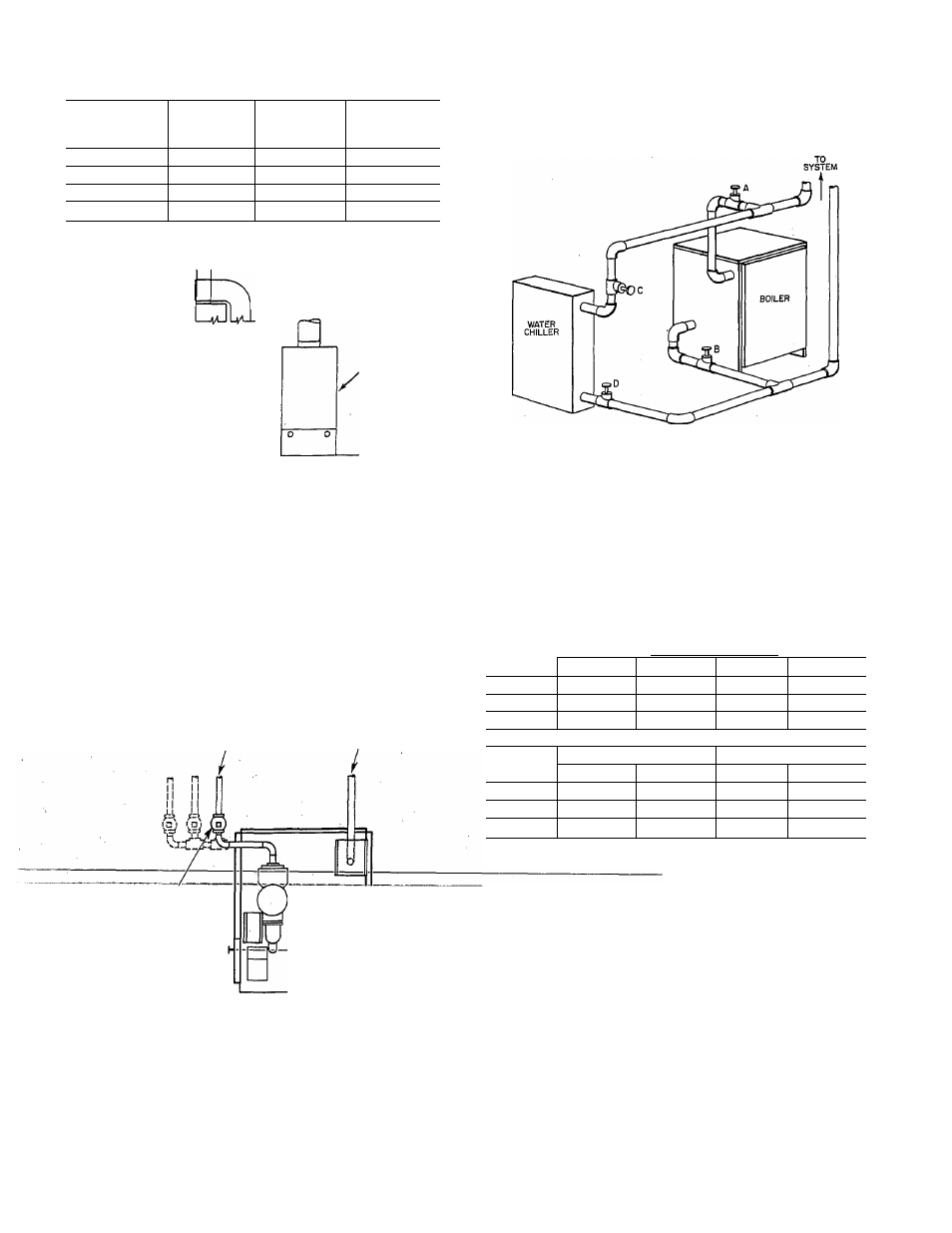

exposed to refrigerated air circulation, the boiler piping system

must be equipped with flow control valves or other automatic

means to prevent gravity circulation of the boiler water during the

cooling cycle.

‘Based on opening mesh soreen, or metal louvers.

FRESH

^AIR

DUCT

FRESH AIR DUCT

FOR TIGHTLY

SEALED HOUSE

BOILER

A90065

Fig. 5—Fresh Air Duct for Tightly Sealed Buildings

side. (See Fig. 6.) Any other piping method will short-circuit water

flow through the boiler and insufficient heat will result from the

premature limit control cutout. When a boiler is installed on an

oversized piping system (a typical example is replacement of a

gravity boiler with a forced circulation boiler) and piping or

radiation are not changed, an adjustable flow control valve or

square head cock must be added to reduce the water flow through

the boiler. This allows proper water temperature (160° F mini

mum) to be obtained which eliminates continuous condensate on

the sections. If more than 1 return is used, use a flow control valve

or square head cock in each return. (See Fig. 6.)

A84191

Fig. 7—Piping With Refrigeration System

Step 5—Gas Piping

The gas supply line should be a separate line directly from the

meter to the boiler, if possible. Refer to Table 4 for the recom

mended gas pipe sizing. Do not use cast-iron or galvanized pipe.

For additional information, refer to “National Fuel Gas Code”

NFPA No. 54-1988/ANSI Z223.1-1988.

Table 4-Gas Pipe/Tubing Capacity

NATURAL GAS

Iron Pipe—Btuh Input

RETURN

SUPPLY

FLOW CONTROL VALVE

OR

SQUARE HEAD COCK

(Ft)*

1/2 in.

3/4 in.

1 in.

1-1/4 in.

20

92,000

190,000

350,000

625,000

40

63,000

130,000

245,000

445,000

60

50,000

105,000

195,000

365,000

PROPANE GAS

Length

Copper Tubing—OD

Iron Pipe

(Ft)*

5/8 in.

3/4 in.

-1/2 in.

3/4 in.

20

131,000

216,000

189,000

393,000

40 .

90,000

145,000

129,000

267,000

60

72,000

121,000

103,000

217,000

‘The length of pipe or tubing should be measured from the gas meter or

propane second stage regulator.

"liTOidTow spbfriiTlohgTTihTbf piperld's'best to'^slope all pipeTiyA--

in. every 15 ft to prevent traps. All horizontal runs should slope

away from the meter to risers. Risers should be used to connect to

the boiler and to the meter.

A84190

Fig. 6—System Water Line Connection

Step 4—Boiler With Refrigeration System

When a water boiler is used in connection with a chilled-water

system, it must be installed so that the chilled medium is piped in

parallel with the heating boiler with appropriate valves to prevent

the chilled medium from entering the heating boiler. An example

of such piping is shown in Fig. 7. When the boiler is connected to

heating coils located in air handling units where they may be

Joint compounds (pipe dope) should be applied sparingly and only

to the male threads of the joints. Consult your local supplier for the

-type-of-compound-to.-berusedzThisTpipe-dQp.ermusl-be-resistant-to-

the action of propane gas.

Install a sediment trap in the riser leading to the boiler. This

sediment trap will serve as a trap for dirt or condensate. This

sediment trap can be installed by connecting a tee to the riser

leading to the boiler, so that the straight-through section of the tee

is vertical. Then, connect a capped nipple into the lower end of the

tee. The capped nipple should extend below the level of the gas

controls. (See Fig. 8.)

When a gum filter is required by local codes, install it in

accordance with their requirements.