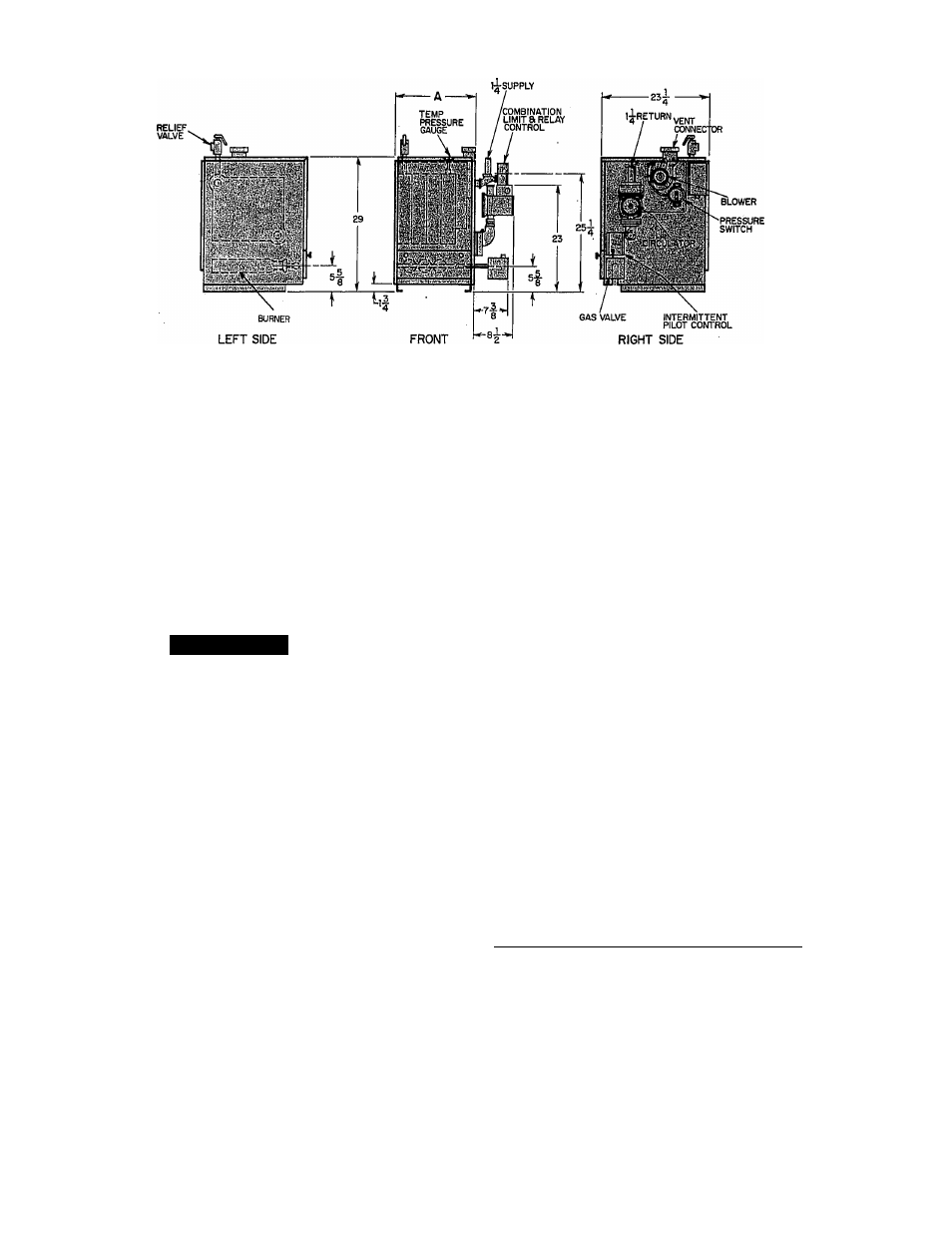

A warning, Table 2—dimensions (in.), Warning – Carrier 61SW User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A85084

Fig. 2—Dimensional Drawing

2. Combustible floors-Do not install the boiler on carpeting.

When the boiler is installed on a combustible floor, you must

use a factory-supplied combustible floor installation kit con

taining a rectangular piece of insulation material. Position the

insulation on the combustible floor and place the boiler on top

of the insulation.

3. Alcove installation only — Maintain at least 6 in. from com

bustible material on the left-hand (LH) side, 6 in. from the

back and 6 in. from the top.

4. Leave enough room for service access on the right-hand (RH)

side and front. A minimum of 24 in. is required.

A

WARNING

The boiler, when installed, must be electrically grounded in

accordance with the National Electrical Code, ANSI/NFPA

No. 70-1988.

Step 2—Air For Combustion and Ventilation

Table 2—Dimensions (In.)

MODEL

AND SIZE

61SW-042100

61SW-075100

61SW-112100

-etsw^rsoioo”

61SW-187100

61SW-225100

11

14-1/4.

17-1/2

■'20-3/4“

24

27-1/4

VENT

CONNECTION

4*

4*

4*

■ 4*~

*With factory-supplied adaptor installed.

The relief-air supply must be in the same atmospheric pressure

zone as the combustion-air inlet supply to the boiler.

^^1 gas-fired equipment must'be'supplied^witlrthe airthat enters’

into the combustion process and is then vented to the outdoors.

Sufficient air must enter the boiler room to replace that air drawn

up the vent stack. Replacement air must be provided by means of

ducts from the outside to the boiler location or conditioned space.

Under all conditions, enough air must be provided to insure there

will not be a negative pressure condition within the boiler room or

space.

In the past, the infiltration of outside air assumed in heat loss

calculations (1 air change per hour) was assumed to be sufficient.

However, current construction methods using more insulation and

WA

vapor barriers, tighter fitting and gasketed doors and windows or

weather-stripping, and mechanical exhaust fans now require the

positive introduction of outside air.

The requirements for combustion and ventilation air depend upon

whether the boiler is located in a confined or unconfined space.

An unconfined space is defined as a space whose volume is not

less than 50 cu ft per 1000 Btuh of the total gas input rating of all

appliances installed in that space.

Advise the owner of the necessity for keeping air passages to the

boiler area free of obstructions. This clearance is necessary so

combustion air can enter freely into the combustion chamber. It is

also necessary to provide adequate ventilating air.

EQUIPMENT LOCATED IN CONFINED SPACES

1. All Air From Inside Building

The confined space shall be provided with 2 permanent

openings communicating directly with an additional room(s)

of sufficient volume so that the combined volume of-all spaces

meets the criteria for an confined space. The total input of all

gas utilization equipment in the confined space shall be

considered in making this determination. Each opening shall

have a minimum free area of 1 square in. per 1000 Btuh of the

total input rating of all gas utilization equipment in the

confined space, but not less than 100 square in. One opening

shall be within 12 in. of the top and 1 within 12 in. of the

bottom of the enclosure. (See Fig. 3.)

—2wUl-Air-FTom-Outdoors-------------------------- ^---------------------------

The confined space shall be provided with 2 permanent

openings, 1 within 12 in. of the top and 1 within 12 in. of the

bottom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl of

attic) that freely communicate with the outdoors.

a. When directly communicating with the outdoors, each

-^^opening^shall-have-a-minimumTreerareamf-l-square-in-per=

4000 Btuh of total input rating of all equipment in the

enclosure. (See Fig. 4.) Use F and G.

b. When communicating with the outdoors with vertical

ducts, each opening shall have a minimum free area of 1

square in. per 4000 Btuh of total input rating of all

equipment within the enclosure. (See Fig. 4.) Use D and E.

c. When communicating with the outdoors with vertical

ducts, each opening shall have a minimum free area of 1

square in. per 2000 Btuh of total input rating of all

equipment in the enclosure. (See Fig. 4.) Use A and B or A

and C.