K caution, Step 5—make electrical connections, Disconnect per n. e. c. and/ or local codes – Carrier 38TMA User Manual

Page 3: Contactor, Fig. a—line power connections, A warning, Caution, Line power connections, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

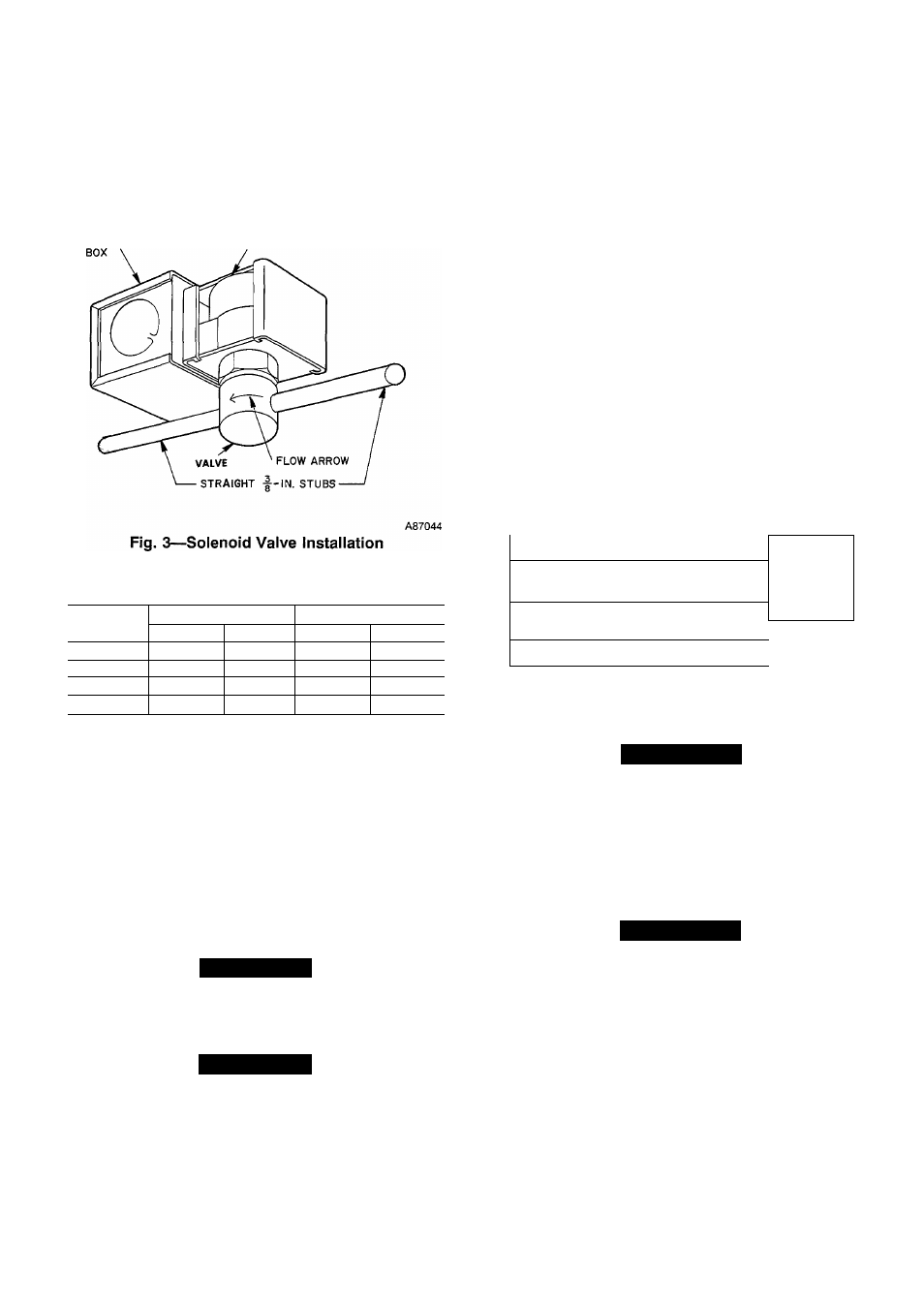

Run refrigerant tubes as directly as possible, avoiding unnecessary

turns and bends. Suspend refrigerant tubes so they do not damage

insulation on vapor tube and do not transmit vibration to structure.

Also, when passing refrigerant tubes through wall, seal opening so

vibration is not transmitted to structure. Leave slack in refrigerant

tubes between structure and unit to absorb vibration.

ELECTRICAL JUNCTION

ELECTRIC COIL

Table 1—Refrigerant Connections and

Recommended Liquid and Vapor Tube Diameters

UNIT SIZE

LIQUID

VAPOR

Conn. Dia.

Tube Dia.

Conn. Dia.

Tube Dia.

024

3/8

3/8

5/8

5/8

030, 036

3/8

3/8

3/4

3/4

042, 048

3/8

3/8

7/8

7/8

060

3/8

3/8

7/8

1-1/8

1. Tube diameters are for lengths up to 50 ft. For tube sets over 50 ft. consult

Long-Line Application Guideline.

2. Do not apply cap-tube indoor coils to these units.

OUTDOOR UNITS CONNECTED TO FACTORY-APPROVED

INDOOR UNITS

Outdoor units contain correct system refrigerant charge for oper

ation with indoor unit of the same size when connected by 25 ft

(7.62m) of field-supplied or factory accessory tubing. Check

refrigerant charge for maximum efficiency (see Refrigerant Charg

ing).

REFRIGERANT TUBING

Connect tubing to fittings on outdoor unit vapor and liquid service

valves. (See Fig. 2.)

£k

CAUTION

A brazing shield MUST be used when tubing sets are being

brazed to the service valves to prevent damage to the painted

unit surface.

A

CAUTION

To avoid valve damage while brazing, service valves must be

wrapped with a heat-sinking material such as a wet cloth.

SWEAT CONNECTION

Use refrigerant grade tubing. Service valves are closed from

factory and ready for brazing. After wrapping the service valve

with a wet cloth, the tubing set can be brazed to the service valve

using either silver bearing or non-silver bearing brazing material.

Consult local code requirements. Refrigerant tubing and indoor

coil are now ready for leak testing. This check should include all

field and factory joints.

Step 5—Make Electrical Connections

Be sure field wiring complies with local and national fire, safety

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE:

Operation of unit on improper line voltage constitute?

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage or phase imbalance may

fluctuate above or below permissible limits.

NOTE;

Use copper wire only between disconnect switch and

unit.

DISCONNECT

PER N. E. C. AND/ OR

LOCAL CODES

CONTACTOR

FIELD POWER

o°o

OoO

WIRING

FIELD GROUND ^

D

WIRING 1 GROUN

A91056

LUG

Fig.

A

—Line Power Connections

A

WARNING

To avoid personal injury or death, do not supply power to unit

with compressor terminal box cover removed.

BRANCH CIRCUIT DISCONNECT

Disconnect must be of adequate size to handle unit starting cunent,

but not larger than maximum fuse size shown on unit rating plate.

Locate disconnect within sight from and ready accessible from

unit, per Section 440-14 of NEC.

A

WARNING

According to NEC, ANSI/NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken ground, to

minimize personal injury if an electrical fault should occur.

The ground may consist of electrical wire or metal conduit

when installed in accordance with existing electrical codes.

Failure to follow this warning could result in an electric

shock, fire, or death.

ROUTE GROUND AND POWER WIRES

Remove access panel and control box cover to gain access to unit

wiring. Extend wires from disconnect through power wiring hole

provided (see Fig. 2) and into unit control box. Size wires per

NEC, but not smaller than minimum wire size shown on unit rating

plate.