A caution, Step 4—make piping connections – Carrier 38TMA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

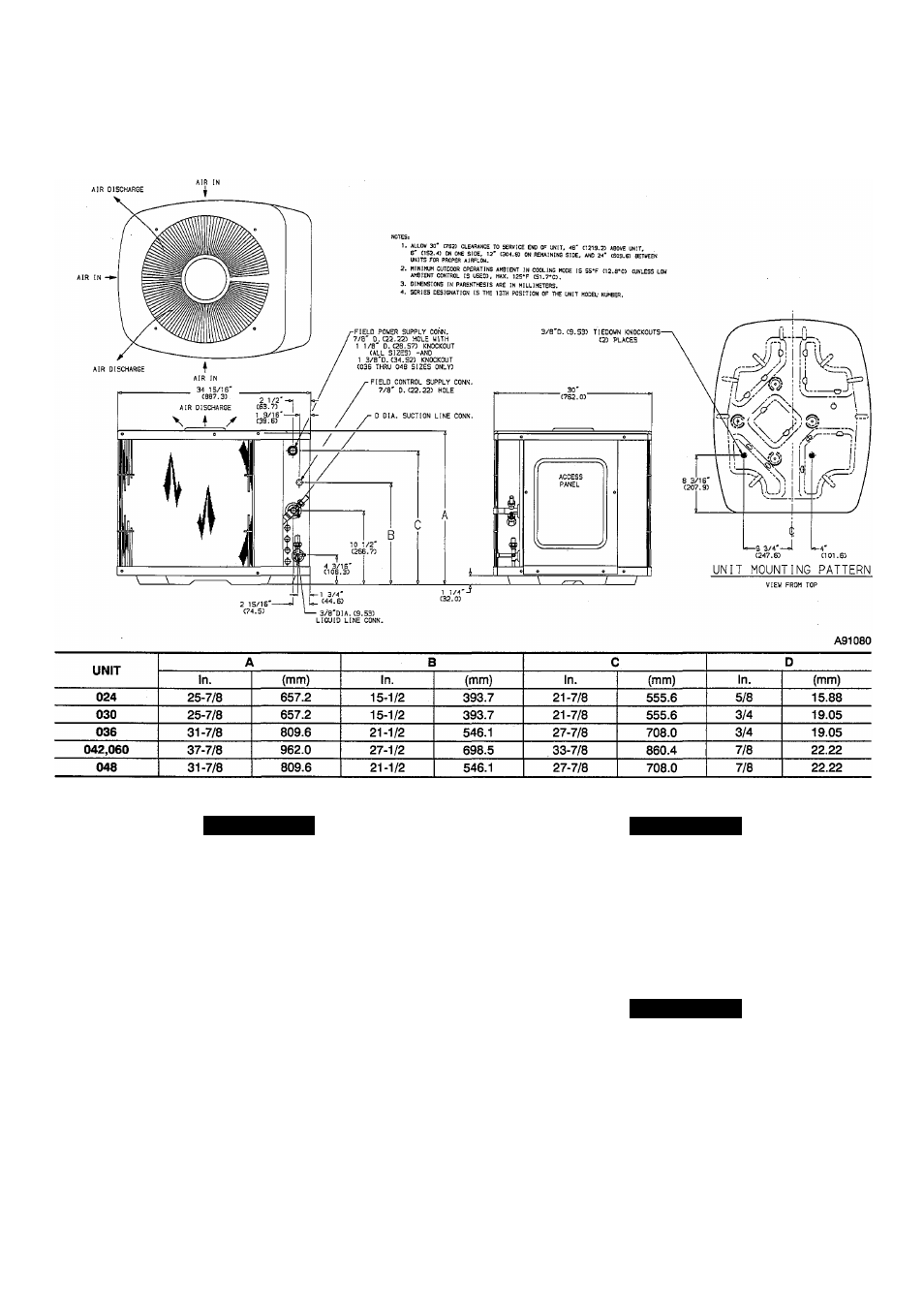

Fig. 2—Unit Reference Drawing

A CAUTION

A CAUTION

If unit is to be installed on system with a thermostatic

expansion valve (TXV), removal of the indoor coU piston is

required.

Step 4—Make Piping Connections

Outdoor units may be connected to indoor sections using accessory

tubing package or field-supplied tubing of refrigerant grade,

correct size, and condition. The liquid- and vapor-tube diameters

can be determined by using Table 1. For tubing requirements

beyond 50 ft (15.24m), obtain information from your local

distributor.

If required, install solenoid valve in liquid line to achieve desired

rating. (See Fig. 3.)

DO NOT BURY MORE THAN 36 IN. (914mm) OF RE

FRIGERANT TUBING IN GROUND. If any section of

tubing is buried, there must be a 6- in.(152mm) vertical rise

to the valve connections on the outdoor unit. K more than the

recommended length is buried, refrigerant may migrate to

cooler buried section during extended periods of unit shut

down, causing refrigerant slugging and possible compressor

damage at start-up.

A CAUTION

For systems installed with a liquid-hue solenoid valve,

solenoid valve must be energized during evacuation and

purging for effective evacuation.

If either refrigerant tubing or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 1000

microns to eliminate contamination and moisture in the system.