Optimizer coimtrou^a^llatioisi, System wiring data (24 v), Optimizer control settings – Carrier 38CQ User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

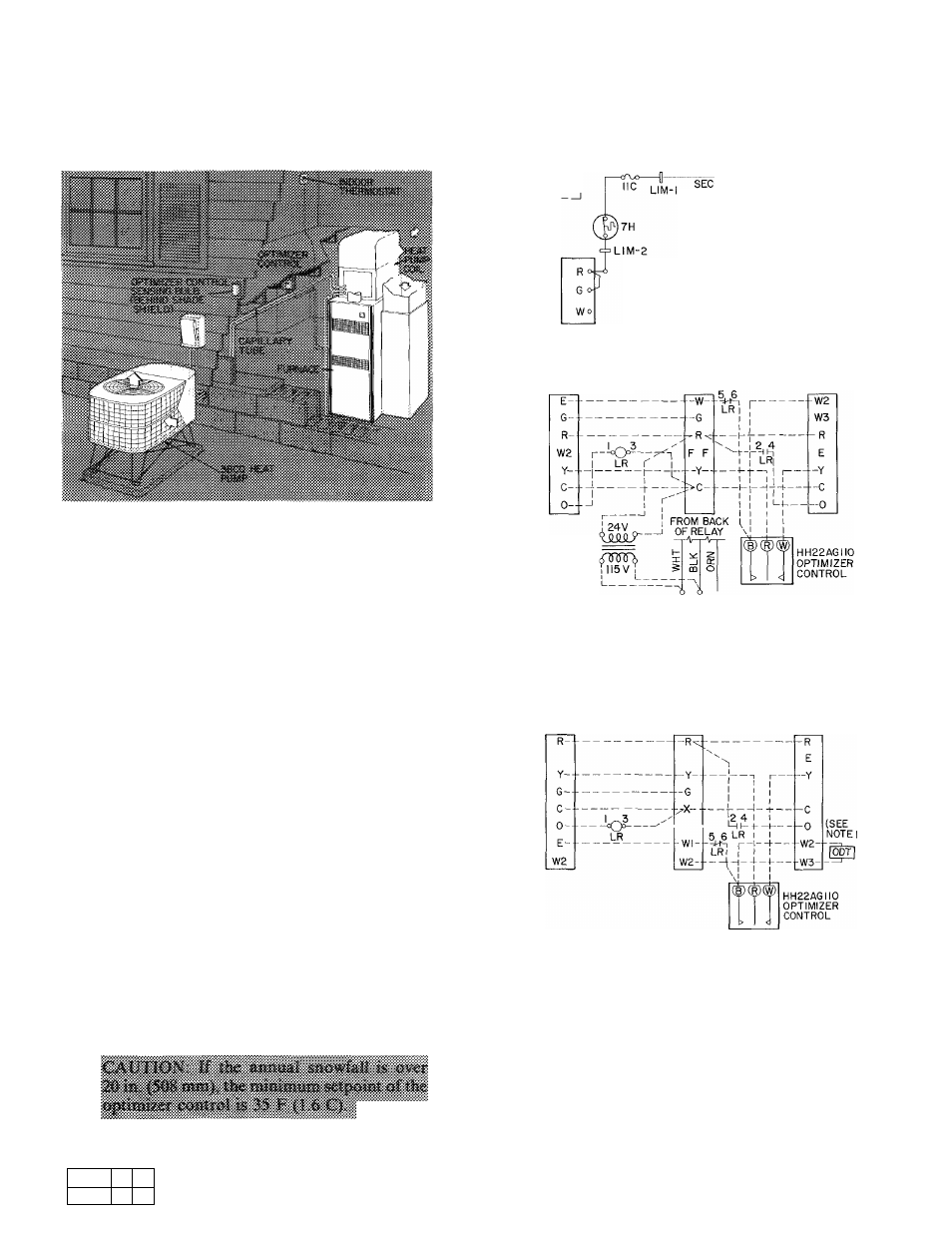

OPTIMIZER COIMTROU^a^LLATIOISI

A 5-ft (1.5 m) capillary tube connects the outdoor

temperature sensing bulb to Optimizer body. Locate

bulb outdoors behind the shade shield. Mount

Optimizer indoors for easy accessibility, Fig. 2.

Fig. 2 — Typical Optimizer Installation

System Wiring Data (24 v)

1. Connect Optimizer system control wiring, Fig. 3.

2. Furnace transformer supplies 24-v power for

system.

3. Required indoor fan relay is energized thru ter

minal G, Fig. 3.

4. Electric furnace terminals R and C must be

powered by transformer 24-v secondary; if not,

change wiring.

5. For example of complete Optimizer system

diagram, refer to heat pump wiring book.

Optimizer Control Settings

^1. Set Optimizer temperature dial to transfer heat

ing function to furnace at a temperature equal

to the calculated balance point plus the control

differential setting (factory set at 10 F [-12.2 C]).

Balance point is usually 30 F (-1.1 C) to 35 F

(1.6 C). Calculation sheets are available from

Carrier. Minimum setting is 20 F (-6.7 C).

2. Factory differential setting is 10 F (-12.2 C).

In areas of less than 20 in. (508 mm) annual snow

fall, setting can be readjusted to 5 F (-15 C).

Remove Optimizer cover for access to differ

ential adjustment wheel.

I

I r ~

L2^LI

LINE-1

LINE-2

1

]

I I________

I

I

I_______

IA "SEC-2

OPTIMIZER SYSTEM-38 SERIES HEAT

PUMP/58SE OR 58GS GAS FURNACE;

COOLING, HEATING, EMERGENCY

HEAT

THERMOSTAT TERMINALS

38CQ900-Ill

(MAN CHANGEOVER)

38CQ900-08I

(AUTO CHANGEOVER)

58H SERIES

OIL FURNACE

PRIMARY RELAY

TERMINALS

HEAT PUMP

TERMINAL BOARD

SUPPLEMENTAL

TRANSFORMER

IF REQUIRED

OPTIMIZER SYSTEM-38 SERIES HEAT PUMP/58H OIL

FURNACE; COOLING. HEATING, EMERGENCY HEAT

CAUTION: The transformer's primary wires must be connected to the black

and white relay wires as shown, since going to LI and L2 would bypass//m/i

switches and make furnace operation unsafe

THERMOSTAT TERMINALS

38CQ900-III

(MAN. CHANGEOVER)

38CQ900-08I

(AUTO. CHANGEOVER)

40 ES

ELECTRIC

FURNACE

TERMINALS

HEAT PUMP

TERMINAL BOARD

OPTIMIZER SYSTEM-38 SERIES HEAT PUMP/40ES ELEC

TRIC FURNACE; COOLING, HEATING, EMERGENCY HEAT

LEGEND

Contacts 1 & 3 = Coil

Contacts 2 & 4 = Normally Open

Contacts 5 & 6 = Normally Closed

LR

— Lockout Relay

NOTES; 1 Place outdoor thermostat across W2 and W3 to limit first stage

"Strip" heat Use jumper wire if outdoor thermostat (ODT) is

not used.

2 Use Carrier part no HK61KK324 relay or any pilot duty lockout

relay (24 v) double-pole, single-throw with one normally open

and one normally closed set of contacts

^ Fig. 3 — Control Circuit Connections

® Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

4

Tab

5a 5a

Form 38CQ-17SIM Supersedes 38CQ-14SI

Printed in U S A

5-80

PC 101

Catalog No 533-839