Carrier 38CQ User Manual

Carrier Conditioners

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Number One

Airconditioning

I\Mer

e

Division of

Carrier Corporatio

Carrier Parkway • Syracuse NY 13221

Installation Instructions

Accessory Optimizer Control

1176

400

55

189

X

12,000 Btuh = 35,280 Btuh

X 3.5 kW = 10.2 kW

Usage

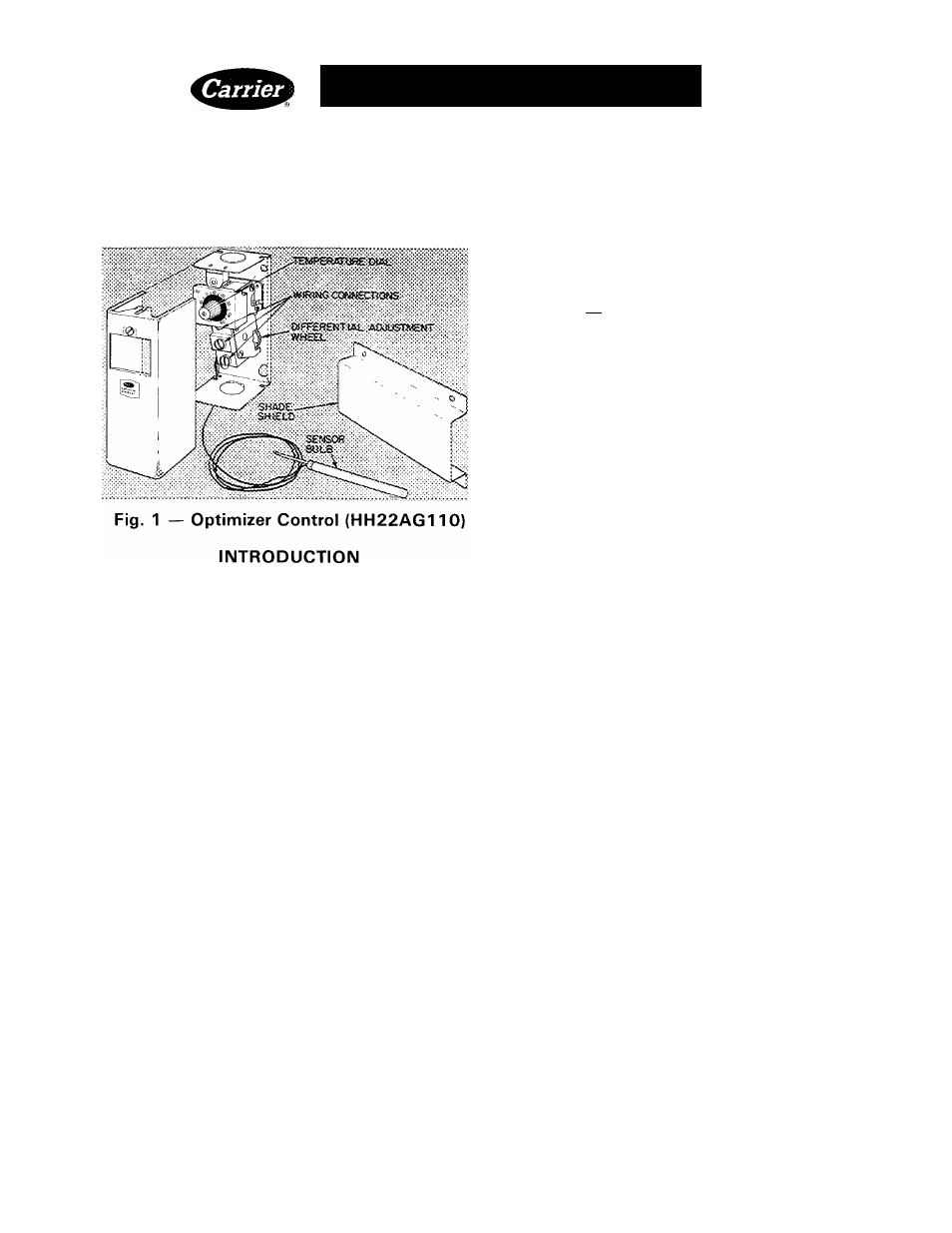

— Install the Optimizer Control (Fig.

1)

with

Model 38CQ, HQ or RQ split system heat pump

that has been added to standard oil or gas furnace.

This Optimizer system provides cooling as required

and heating season operation that maximizes system

usage and benefits.

Optimizer usage is also beneficial in some heat

pump/electric furnace systems such as those with

Model 40ES. These Optimizer systems operate the

same as gas or oil furnace/heat pump systems.

CAUTION: If

saowfaB is over 20 in.

(508 mm), the minimum setpoint of the Opti

mizer Control is 35 F (L6 C),

OPTIMIZER SYSTEM

INSTALLATION REQUIREMENTS

^Indoor Airflow Capacity

of furnace fan and duct

system, as is, or with modification, must be approxi

mately 400 to 500 cfm per 12,000 Btuh (189 to 236 1/ s

per 3.5 kW) of heat pump cooling capacity (equiv

alent to 33 to 42 cfm per 1,000 Btuh [15.6 to 19.8 1/s

per .3 kW]). Determine existing system cfm capa

bility (without indoor coil installed) by standard

temperature rise or pressure drop methods. Calcu

late permissible cooling capacity.

Example:

System cfm capability = 1176 cfm (555 1/s)

Maximum heat pump cooling capacity permis

sible at 1176 cfm (555 1/s) with minimum require

ment of 400 cfm (189 1/s)/12,000 Btuh (3.5 kW):

With indoor coil installed, a larger furnace motor

or blower assembly may be required. After installing

coil, recheck cfm, and modify blower assembly or

duct system as required.

RECOMMENDED INDOOR COIL LOCATION

is on supply air side of gas or oil furnace, supply or

return air side of Electric Furnace (40ES). See

Fig. 2 and Coi/ Installation Instructions.

SYSTEM

INDOOR

THERMOSTAT

—

Use

thermostat-subbase

package

38CQ900-111

for

manual cooling/heating changeover; 38CQ900-081

for automatic cooling/heating changeover. Re

quired thermostat has manually operated emer

gency heat switch which locks out heat pump and

activates furnace.

SYSTEM TRANSFORMER (24-v) CAPACITY

required for most Optimizer systems is 60 va.

Replace gas or electric furnace transformer as re

quired with 60-va transformer. Carrier Part No.

HT01AW230.

If oil furnace has a 40-va (or less) transformer, and

accessory humidifier or air cleaner is wired in system,

add another transformer to system to acquire 60-va

total transformer capacity. Connect additional

transformer in parallel and in phase with existing

transformer as follows:

1. Connect 115-volt primary leads on 20-va trans

former to same points as primary leads on exist

ing transformer.

2. Attach one 24-volt secondary lead from 20-va

transformer to furnace terminal C or common

side of existing transformer.

3. Apply 115-volt power. Measure voltage between

unconnected 24-v lead, on 20-va transformer,

and terminal R on furnace. If voltage is zero,

connect 24-v lead to terminal R. (Transformers

are in phase.) If 50 volts (approximately) is

measured, reverse 115-v primary lead connection

on one transformer. Recheck voltage — if zero,

connect 24-v lead to terminal R.

FURNACE FAN RELAY is required. Add to fur

nace when not so equipped. Furnaces shown in

Control Circuit Connections, Fig. 3, have fan relay.

Carrier Corporation 1980

Form 38CQ-17SIM