Carrier WEATHERMASTER 36TE User Manual

Bypass weathermaster® air terminals, Carrier, Ctíons

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier

ctíons

^ (p 7^h - jr /Q-yc^

Bypass Weathermaster® Air Terminals

INTRODUCTION

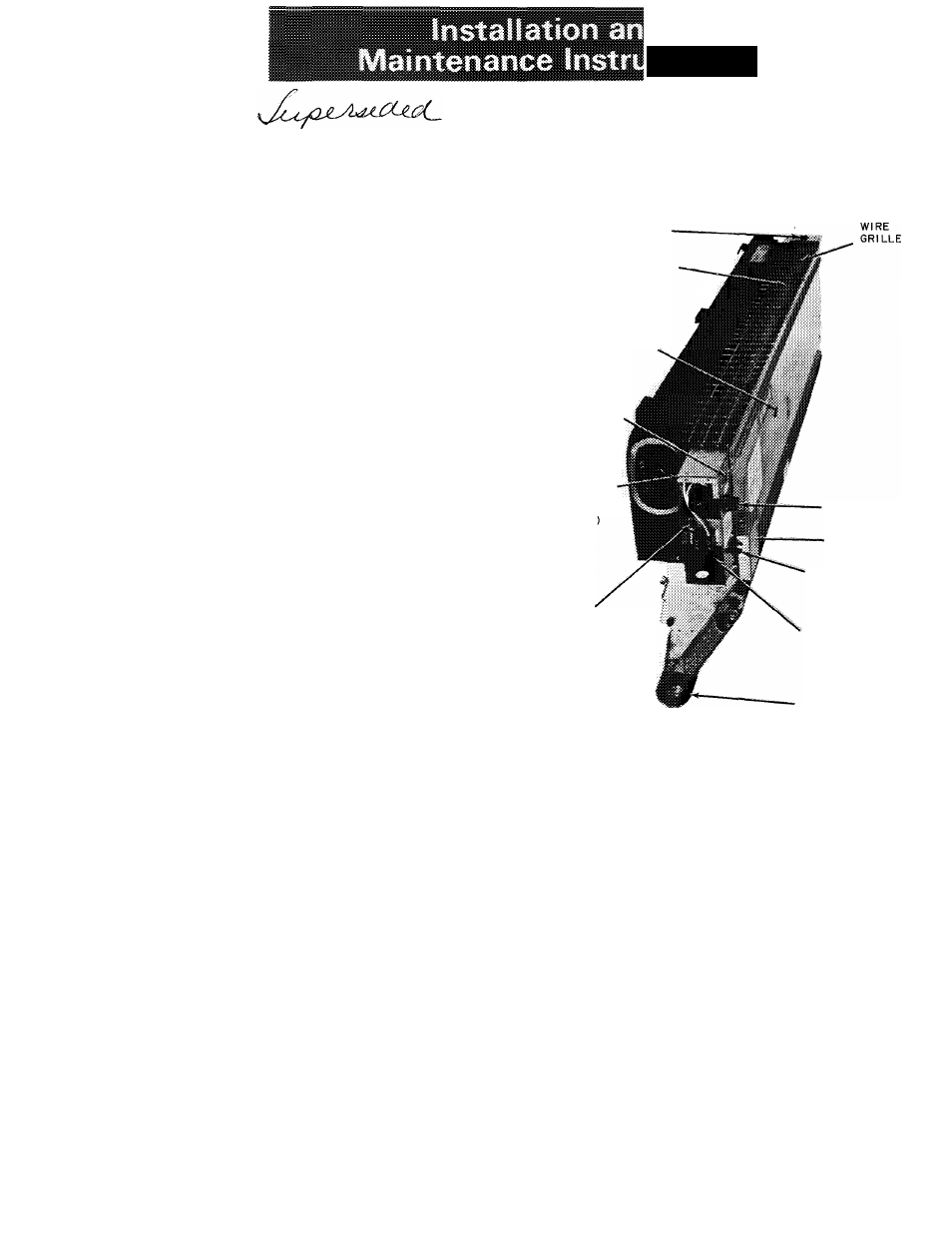

The 36TE unit (see Fig. 1) is a nonchangeover

version of the 36RV Bypass WEATHERMASTER

Air Terminal with an electriciresistance heater. It

consists of an air inlet, sound absorbing plenum,

balancing damper, primary air nozzles, bypass damp

er assembly, secondary coil, and condensate pan.

Controls for this unit are either self-contained

or wall mounted: the thermostat can be mounted

on the right-hand side of the unit or on the wall;

the electrical controls are mounted on the left-

hand side of the unit. Electrical controls include an

On-Off toggle switch, fuse holder, fuse, micro

switch, terminal block, automatic high-temperature

Umit switch, and a manual reset temperature limit

switch.

When the unit thermostat senses a cold room

temperature, it causes the bypass damper to close.

Induced room air is then directed around the

secondary coil. When the damper reaches its full

bypass position, it contacts the microswitch which

activates the heater.

This publication is designed as a supplement to

the 36R Installation Instructions. Since the 36RV

and 36TE units are similar, installation of the

36TE unit is the same as that described for the

36RV unit with the changes noted in this pubhca-

tion. Refer also to the 36R literature for unit and

enclosure dimensional data.

When unpacking unit, should any in-transit

damage be observed, file claim with transportation

agency.

INSTALLATION

Unit Installation

1. Follow procedures outlined for installation of

the 36RV air terminals. Refer to 36R Installa

tion Instructions for details.

2.

Do not remove protective cover from unit

discharge unless discharge grille is being in

stalled. If construction debris is still present in

area, keep discharge covered to prevent debris

from getting into unit heater.

Wiring

1. Observe national and local codes.

2. Check to ensure that unit nameplate voltage

corresponds with the line voltage available at

the job site. Do not exceed the allowable

voltage variation of ± 10 percent.

3. Make line voltage connections to terminal block

in control box on unit. Make ground connec

tion to green screw above terminal block. (See

Fig. 1 and Fig. 2.)

THERMOSTAT

ELECTRIC

RESISTANCE

HEATER

DAMPER

ADJUSTMENT

SCREW (SEE FIG 3)

MANUAL RESET

TEMPERATURE

LIMIT SWITCH

ELECTRICAL

CONTROL BOX

{COVER

REMOVED

GROUND

(CONNECTION)

FUSE

MICROSWITCH

ON-OFF

TOGGLE SWITCH

TERMINAL BLOCK

CONDENSATE PAN

Fig. 1 -36TE Bypass WEATHERMASTER

Air Terminal

4. Refer to Table 1 for electrical data and usage.

NOTE: Whenever the fan in the central station

air handling apparatus is shut down, make sure

that the electric resistance heater located in the

36TE unit discharge is inoperative To ensure

this, the heater circuit should be interlocked

with the apparatus fan.

Unit Balancing

1. Remove construction debris from unit and

make sure that protective plastic has been

removed from thermostat cover.

2. Units are shipped with plenum damper wide

open. Turn damper adjustment screw, which is

located in the front of the unit (see Fig. 1 and

Fig. 3), clockwise to close damper and decrease

nozzle pressure to design value. (Minimum

allowable nozzle pressure is 1.0 in. wg.) Two or

three runs may be necessary to obtain proper

balance. (See Fig. 3.)

NOTE: 36TE unit requires minimum 1.5 in. wg

plenum pressure for control operation; maxi

mum allowable plenum pressure is 5 in. wg.

©Carrier Corporation 1972

Form 36TE-1SI