Storage & maintenance, Maintenance requirements, Cleaning – Winco W10PTOS/A User Manual

Page 9: Lubrication

3225-00

60706-241

10. Slowly reduce power take-off speed to a minimum and

disengage the power take-off. Some tractors have a

brake on the power take-off that stops the shaft in-

stantly. Stopping the alternator rotor instantly from rated

speed may result in a broken shaft or other drive line

failures.

WARNING: Personal Injury

Never try to manually stop the generator. Always let it coast

until it stops

.

11. Shut off the engine.

12. Disconnect drive shaft (tumbling bar)

power take-off end first, then generator end.

13. Exercise PTO alternator for one hour under load at least

twice a year.

STORAGE & MAINTENANCE

If the generator is mounted on an off-high-

way trailer, such as the Winco trailer, it

should be stored in a garage, barn or ma-

chine shed in a dry and clean location. The

generator should be covered with a tarpaulin

to prevent the entrance of dust, chaff, and/or

moisture.

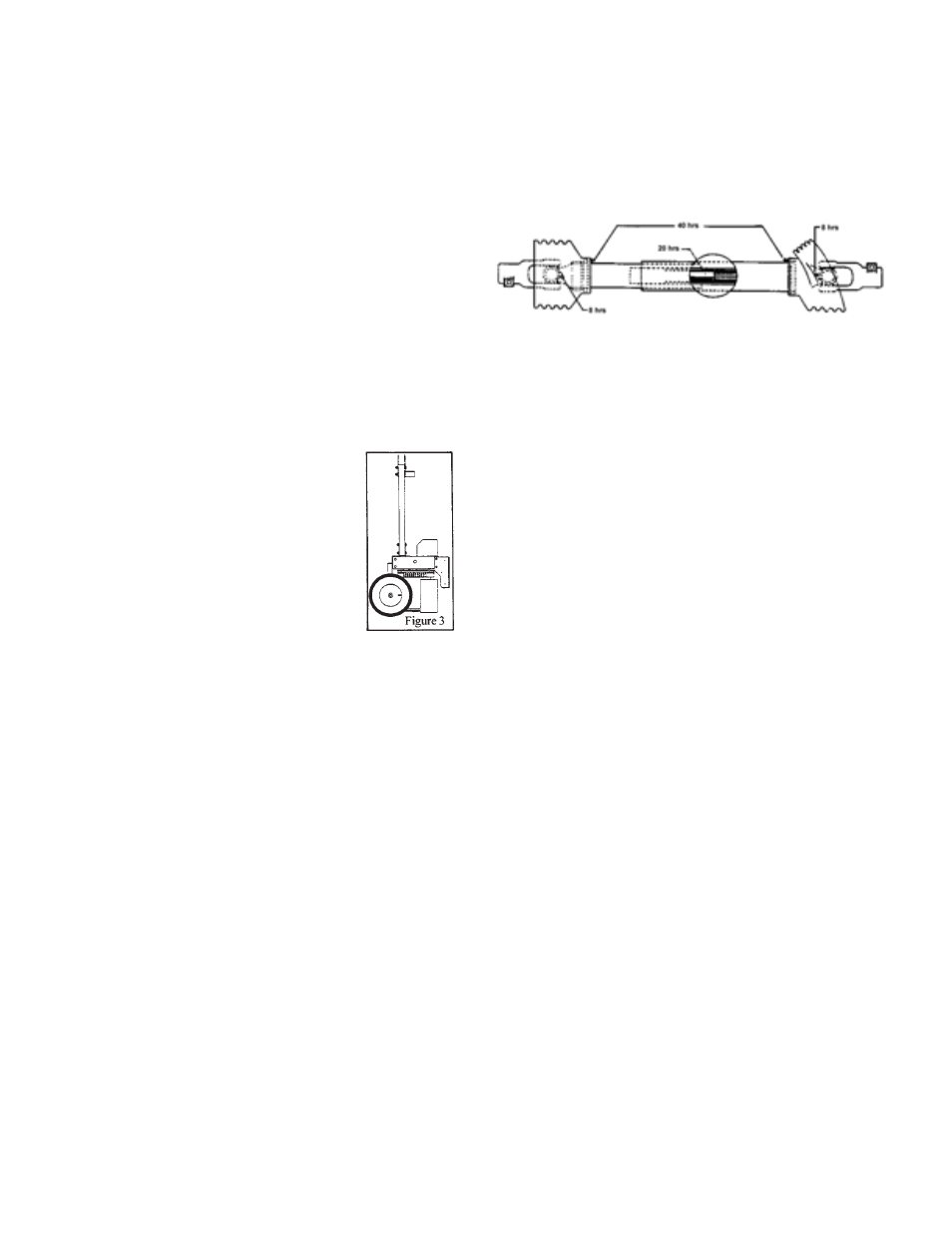

The generator may be stored on end,

provided the generator is on a clean, dry el-

evated surface such as a board. Do not have

it resting on a dirt surface. (Figure 3)

MAINTENANCE REQUIREMENTS

LUBRICATION

A. Check the generator gear case oil level before each use

of the generator. See Figure 4. Maintain the oil level before

each use of the generator. Maintain the oil level at oil level plug

height. The generator is shipped with lubricant in the gear case.

Specifications for gear case lubricant are: API Service: GL-5 EP

Rated, Grade: SAE 85W-90-140, Amount: 1 pint. The following

kinds of oil are recommended for use in the generator gear case:

Mobil SAE 85W90-140 API Service GL-5

Sunoco/DX XL80W90-140

Kendal Three Star 85W-140

Amoco 85W140 or equivalent

CAUTION: Equipment Damage

Do not overfill generator gear case. Overfilling causes overheat-

ing and oil seal failure.

B. The generator bearings are factory lubricated and sealed,

and require no further lubrication.

C. The splined generator input shaft should be cleaned and

lubricated with a thin film of grease before and after each use of

the generator. See Figure 6 for lubrication schedule.

D. The drive shaft (tumbling bar) requires greasing. Keep the

universal joints in the coupling shaft free from grease and dirt

buildup.

NOTE: Do not over lubricate

the universal joints.

CLEANING

A. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end, circuit

breakers, and receptacles.

B. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indication of

the entrance of mice or insects into the generator. The inlet and

outlet openings are louvered, but possible damage to the louvers

could occur. Mice can destroy the generator winding.

WARNING: Equipment Damage

DO NOT CLEAN THE GENERATOR WHILE IT IS RUNNING.

Page 7

60706-180

0310-00

Figure 6

STORAGE & MAINTENANCE

If the generator is mounted on an off-highway

trailer, such as the Winco trailer, it should be

stored in a garage, barn or machine shed in a

dry and clean location. The generator should

be covered with a tarpaulin to prevent the

entrance of dust, chaff, and/or moisture.

The generator may be stored on end, provided

the generator is on a clean, dry elevated

surface such as a board. Do not have it resting

on a dirt surface. (Figure 3)

MAINTENANCE REQUIREMENTS

LUBRICATION

1. Check the generator gear case oil level before each use of

the generator. See Figure 4. Maintain the oil level before

each use of the generator. Maintain the oil level at oil level

plug height. The generator is shipped with lubricant in the

gear case. Specifications for gear case lubricant are: API

Service: GL-5 EP Rated, Grade: SAE 85W-90-140,

Amount: 1 pint. The following kinds of oil are recom-

mended for use in the generator gear case:

Mobil SAE 85W90-140 API Service GL-5

Sunoco/DX XL80W90-140

Kendal Three Star 85W-140

Amoco 85W140 or equivalent

CAUTION: Equipment Damage

Do not overfill generator gear case. Overfilling causes

overheating and oil seal failure.

2. The generator bearings are factory lubricated and sealed,

and require no further lubrication.

3. The splined generator input shaft should be cleaned and

lubricated with a thin film of grease before and after each

use of the generator. See Figure 6 for lubrication sched-

ule.

4. The drive shaft (tumbling bar) requires greasing. Keep the

universal joints in the coupling shaft free from grease and

dirt buildup.

NOTE: Do not over lubricate

the universal joints.

CLEANING

1. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end,

circuit breakers, and receptacles.

2. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indica-

tion of the entrance of mice or insects into the generator.

The inlet and outlet openings are louvered, but possible

damage to the louvers could occur. Mice can destroy the

generator winding.

WARNING: Equipment Damage

DO NOT CLEAN THE GENERATOR WHILE IT IS RUNNING.

CAUTION: Equipment Damage

Most electrical equipment in North America operates

satisfactorily at frequencies between 59 and 61 Hz (cycles

per second). Operating the generator at frequencies

outside that range may cause damage to the generator

and/or to electrical equipment driven by the generator.

Page 7

60706-180

0310-00

Figure 6

STORAGE & MAINTENANCE

If the generator is mounted on an off-highway

trailer, such as the Winco trailer, it should be

stored in a garage, barn or machine shed in a

dry and clean location. The generator should

be covered with a tarpaulin to prevent the

entrance of dust, chaff, and/or moisture.

The generator may be stored on end, provided

the generator is on a clean, dry elevated

surface such as a board. Do not have it resting

on a dirt surface. (Figure 3)

MAINTENANCE REQUIREMENTS

LUBRICATION

1. Check the generator gear case oil level before each use of

the generator. See Figure 4. Maintain the oil level before

each use of the generator. Maintain the oil level at oil level

plug height. The generator is shipped with lubricant in the

gear case. Specifications for gear case lubricant are: API

Service: GL-5 EP Rated, Grade: SAE 85W-90-140,

Amount: 1 pint. The following kinds of oil are recom-

mended for use in the generator gear case:

Mobil SAE 85W90-140 API Service GL-5

Sunoco/DX XL80W90-140

Kendal Three Star 85W-140

Amoco 85W140 or equivalent

CAUTION: Equipment Damage

Do not overfill generator gear case. Overfilling causes

overheating and oil seal failure.

2. The generator bearings are factory lubricated and sealed,

and require no further lubrication.

3. The splined generator input shaft should be cleaned and

lubricated with a thin film of grease before and after each

use of the generator. See Figure 6 for lubrication sched-

ule.

4. The drive shaft (tumbling bar) requires greasing. Keep the

universal joints in the coupling shaft free from grease and

dirt buildup.

NOTE: Do not over lubricate

the universal joints.

CLEANING

1. Inspect for loose or broken wiring connections. Make sure

that wiring connections are not loose at the generator end,

circuit breakers, and receptacles.

2. Do not allow dirt or chaff to collect in the interior of the

generator or the ventilation openings. Inspect for indica-

tion of the entrance of mice or insects into the generator.

The inlet and outlet openings are louvered, but possible

damage to the louvers could occur. Mice can destroy the

generator winding.

WARNING: Equipment Damage

DO NOT CLEAN THE GENERATOR WHILE IT IS RUNNING.

CAUTION: Equipment Damage

Most electrical equipment in North America operates

satisfactorily at frequencies between 59 and 61 Hz (cycles

per second). Operating the generator at frequencies

outside that range may cause damage to the generator

and/or to electrical equipment driven by the generator.