Preparing the unit, Features and controls, Operation – Winco WC10000VE/E User Manual

Page 5: Unpacking, Lubrication, Oil recommendations

5

2015-00

60706-232

Self-exciting generators respond to severe overload-

ing differently than utility power. When overloaded,

the engine is not able to supply enough power to

bring the electric motor up to operating speed. The

generator responds with high initial starting current,

but the engine speed drops sharply. The overload

may stall the engine. If allowed to operate at very

low speeds, the electric motor starting winding will

burn out in a short time. The generator winding

might also be damaged.

CAUTION: EQUIPMENT DAMAGE

RUNNING THE GENERATOR SET UNDER

THESE CONDITIONS MAY RESULT IN DAMAGE

TO THE GENERATOR STATOR AS WELL AS THE

MOTOR WINDING.

The heavy surge of current required for starting

motors is required for only an instant. The genera-

tor will not be damaged if it can bring the motor up

to speed in a few seconds of time. If difficulty is

experienced in starting motors, turn all other electri-

cal loads off and if possible reduce the load on the

electric motor.

PREPARING THE UNIT

UNPACKING

CAUTION: EQUIPMENT DAMAGE

THIS UNIT HAS BEEN SHIPPED

WITHOUT OIL.

Failure to maintain the engine oil at the proper level

will result in serious engine damage.

When you unpack your new engine-generator set be

sure to remove all the information sheets and manu-

als from the carton.

1. This generator-set was in good order when

shipped. Inspect the generator-set promptly after

receiving it. If any damage is noted, notify the trans-

portation company immediately; request proper pro-

cedures for filing a “concealed damage” claim. Title

to the equipment and responsibility for filing a claim

rests with you when a generator-set is sent F.O.B.

shipping point. Only you can legally file a claim.

2. Before proceeding with the preparations of your

new generator-set for operation, take a couple of

minutes to insure the unit you have received is the

correct model and review the specification pages in

this manual to insure that this unit meets your job

requirements.

LUBRICATION

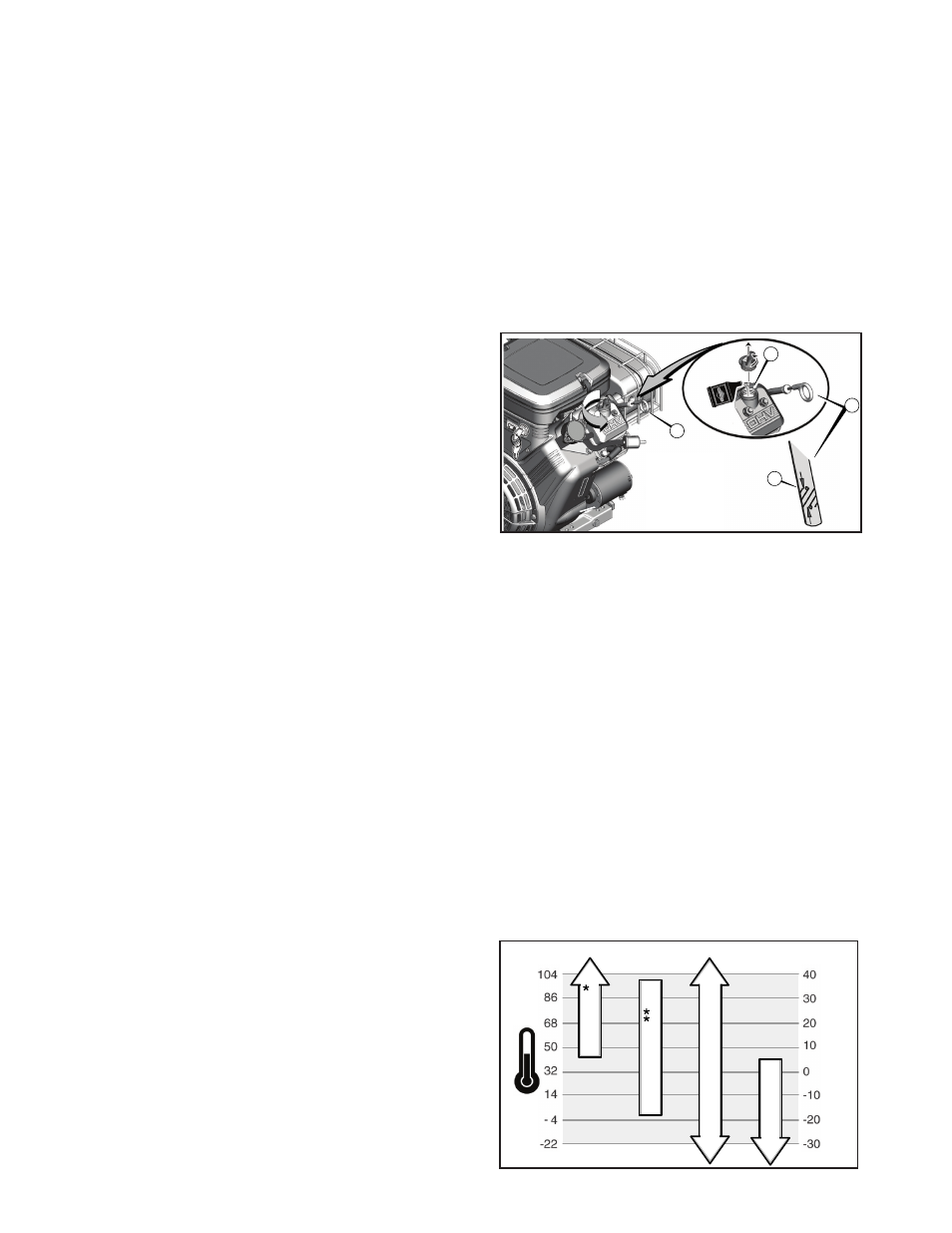

Before starting the engine, fill the crankcase to the

proper level with a good quality oil. The recom-

mended grade of oil and quantity of oil required is

listed in the engine operator’s manual and under the

service tab in this manual. This unit was shipped

with most of the oil removed. The engine normally

holds 46 and 48 ounces of oil. Since there is some

trapped oil in the engine, when filling the crankcase

the first time use the dipstick (ref “A”) to ensure that

you do not over fill the crankcase. Reference “B”

shows the full oil level mark on the dipstick.

Oil is added to the engine by removing the oil fill cap

(ref “C”) and adding oil at this point. After filling the

crankcase to the proper level, be sure you properly

tighten the oil fill cap. NOTE: This engine generator

must be on a level surface before you check or add

oil to the system.

The necessity of using the correct oil, and keeping

the crankcase full cannot be overemphasized. En-

gine failures resulting from inadequate or improper

lubricant are considered abuse and not covered by

the generator or engine manufacturer’s warranty.

Oil Recommendations

Outdoor temperatures determine the proper oil

viscosity for the engines. Use the chart to select the

best viscosity for the outdoor temperature range

expected.

3

A

C

2

A

3

B

C

E

A

B

A

C

C

E

C

D

F

B

F

D

4

F

A

A

B

5

6

A

B

A

B

B

C

B

7

D

C

A

7

en

Features and Controls

Compare the illustration

1

with your engine to familiarize yourself with the location of

various features and controls.

A. Engine Identification

Model Type Code

B. Spark Plug

C. Air Cleaner (without Fuel Tank)

D. Air Cleaner (with Fuel Tank)

E. Dipstick

F.

Oil Fill

G. Oil Filter (optional)

H. Oil Drain Plug

I.

Oil Pressure Sensor

J.

Finger Guard

K. Electric Starter

L. Rewind Starter (optional)

M. Carburetor

N. Muffler (optional)

O. Fuel Pump

P.

Starter Switch *

Q. Throttle Control *

R. Choke Control *

S. Fuel Filter (optional)

T.

Fuel Tank (optional)

U. Fuel Shut Off (optional) *

V. Stop Switch (optional) *

W. Oil Cooler (optional)

* Some engines and equipment have remote controls. See the equipment manual for

location and operation of remote controls.

Operation

Oil capacity (see the Specifications section)

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty Certified oils for best

performance. Other high-quality detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to

select the best viscosity for the outdoor temperature range expected.

S

A

E

30

10

W

-30

S

yn

th

et

ic

5W

-3

0

5W

-30

°F

°C

*

Below 40

°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80

°F (27°C) the use of 10W-30 may cause increased oil consumption. Check

oil level more frequently.

How To Check/Add Oil - Figure 2

Before adding or checking the oil

x

Place engine level.

x

Clean the oil fill area of any debris.

1. Remove the dipstick (A) and wipe with a clean cloth (Figure 2).

2. Fully insert the dipstick.

3. Remove the dipstick and check the oil level. It should be at the top of the full indicator

(B) on the dipstick.

4. If low, add oil slowly into the engine oil fill (C). Do not overfill. After adding oil, wait

one minute and then recheck the oil level.

5. Fully insert the dipstick.

Oil Pressure

If the oil pressure is too low, a pressure switch (if equipped) will either stop the engine or

activate a warning device on the equipment. If this occurs, stop the engine and check the

oil level with the dipstick.

If the oil level is below the ADD mark, add oil until it reaches the FULL mark. Start the

engine and check for proper pressure before continuing to operate.

If the oil level is between the ADD and FULL marks, do not start the engine. Contact an

Authorized Briggs & Stratton Dealer to have the oil pressure problem corrected.

Fuel Recommendations

Fuel must meet these requirements:

x

Clean, fresh, unleaded gasoline.

x

A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

x

Gasoline with up to 10% ethanol (gasohol) is acceptable.

CAUTION: Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in

gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will

damage the engine components and void the engine warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See

Storage. All fuel is not the same. If starting or performance problems occur, change fuel

providers or change brands. This engine is certified to operate on gasoline. The

emissions control system for this engine is EM (Engine Modifications)

.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON)

gasoline is acceptable. To remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause decreased performance,

increased fuel consumption, and increased emissions.See an authorized Briggs &

Stratton Dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

How To Add Fuel - Figure 3

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

x

Turn engine off and let engine cool at least 2 minutes before removing the fuel

cap.

x

Fill fuel tank outdoors or in well-ventilated area.

x

Do not overfill fuel tank. To allow for expansion of the fuel, do not fill above the

bottom of the fuel tank neck.

x

Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

x

Check fuel lines, tank, cap, and fittings frequently for cracks or leaks.

Replace if necessary

x

If fuel spills, wait until it evaporates before starting engine.

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap (A, Figure 3).

2. Fill the fuel tank (B) with fuel. To allow for expansion of the fuel, do not fill above the

bottom of the fuel tank neck (C).

3. Reinstall the fuel cap.

How To Start The Engine - Figure 4

Rapid retraction of starter cord (kickback) will pull hand and arm

toward engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

WARNING

x

When starting engine, pull the starter cord slowly until resistance is felt and then

pull rapidly to avoid kickback.