Engine care, Maintenance – Winco WC10000VE/E User Manual

Page 11

11

2015-00

60706-232

To connect these units directly to an un-powered,

isolated construction site TemPower panel, have

your electrician connect to the control panel using a

120/240 volt, 4-wire twist-lock plug (14-60P).

NOTE: Never attempt to use the 240 volt three wire

receptacle to wire into a building. This is a GFCI

circuit and is designed for 240 volt output only. It has

no neutral connection. If you attempt to draw 120 volt

from this receptacle the GFCI breaker will trip.

2. If the generator set is be connected to an existing

distribution system, a fully isolated manual trans-

fer switch must be installed. The transfer switch

prevents damage to the generator and other circuit

components if main line power is restored while the

generator is connected. Installing a transfer switch

also permits the use of normal fusing.

3. Many homes and construction sites are wired

for at least 60 to 100 Amp entrance service, much

greater than the capacity of this portable genera-

tor. When installing the generator at these sites, a

secondary emergency distribution panel may have to

be installed, such as the Emergency Transfer/Service

(ET/S) system available through your WINCO dealer.

The emergency distribution panel must be installed

by a licensed electrician according to all applicable

codes. The electrician will move the critical circuits

to be powered during the outage to the emergency

panel. Keep in mind only a limited amount of amper-

age is available from the generator set. Some circuit

breakers may still have to be turned off to prevent an

overload on the generator during the initial start up.

See the nameplate on your generator for the amper-

age capabilities of your unit.

CAUTION: EQUIPMENT DAMAGE

Failure to properly limit and balance the load ap-

plied to the generator will cause the generator to

produce low voltage and may damage the engine

generator set. It may also cause severe damage to

the loads connected to the generator at that time. Im-

proper loading of the generator set constitutes abuse

and will not be covered by warranty.

ENGINE CARE

If major engine service or repair is required, contact

an authorized engine service center. The manufac-

turer of these engines has established an excellent

world-wide engine service organization. Engine ser-

vice is very likely available from a nearby authorized

dealer or distributor. Check the yellow pages of your

local telephone directory under “Engines-Gasoline”

for the closest engine repair center or ask the dealer

from whom you purchased the power plant.

1.

Change the oil after the first 5 hours of opera-

tion and yearly or 100 hours thereafter under normal

operating conditions. Change engine oil every 50

hours of operation if the engine is operated under

heavy load, or in high ambient temperatures.

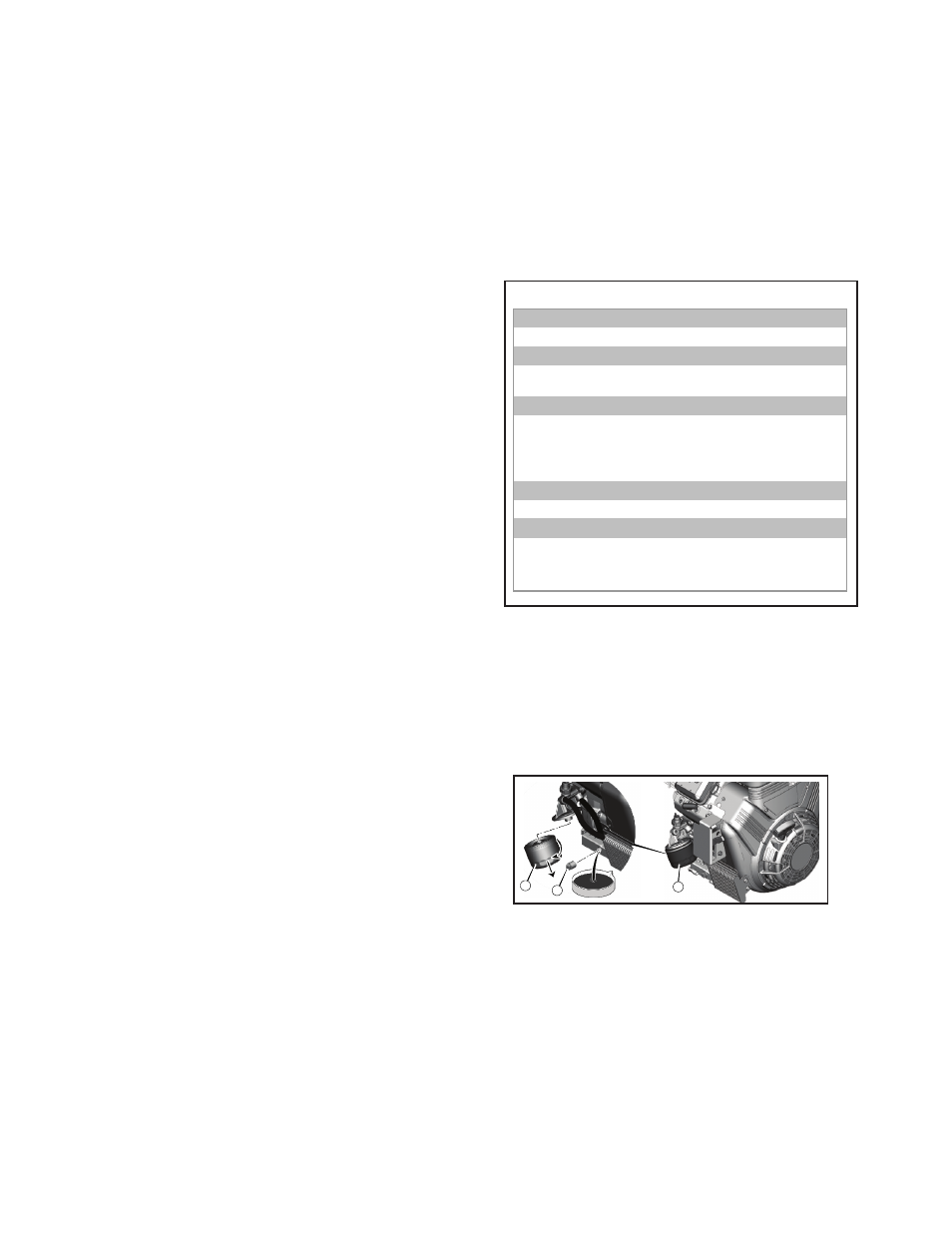

a. Start the engine and warm it up, stop the engine

and remove the spark plug wire to prevent it

from accidently being started.

b. Remove oil drain plug at base of the engine

(Ref “B”) and drain the oil into an approved

container.

c. Remove the oil filter (Ref “C”) and dispose of it

properly.

d. Before you install the new oil filter, lightly lubri-

cate the oil filter gasket with fresh clean oil.

e. Install the oil filter by hand until the gasket

contacts the oil filter adapter, then tighten the oil

filter 1/2 to 3/4 turns.

f. Replace oil drain plug.

4

VanguardEngines.com

E

D

A

8

F

D

C

9

C

B

10

A

B

B

C

D

11

A

B

F

E

D

G

12

C

B

C

D

E

G

F

8

VanguardEngines.com

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Starting Engine

x

Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in

place and secured.

x

Do not crank engine with spark plug removed.

x

If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle

(if equipped) to FAST position and crank until engine starts.

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

WARNING

x

Start and run engine outdoors.

x

Do not start or run engine in enclosed area, even if doors or windows are open.

NOTICE: This engine was shipped from Briggs & Stratton without oil. Before you start

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

Note: Some engines and equipment have remote controls. See the equipment manual

for location and operation of remote controls.

1. Check the oil level. See the How To Check/Add Oil section.

2. Make sure equipment drive controls, if equipped, are disengaged.

3. Turn the fuel shut-off valve (A), if equipped, to the on position (Figure 4).

4. Push the stop switch (F), if equipped, to the on position.

5. Move the throttle control (B) to the fast

position. Operate the engine in the fast

position.

6. Move the choke control (C) to the choke

position.

Note: Choke is usually unnecessary when restarting a warm engine.

7. Rewind Start: Turn the key switch (D), if equipped, to the run position.

8. Rewind Start: Firmly hold the starter cord handle (E). Pull the starter cord handle

slowly until resistance is felt, then pull rapidly.

Note: If the engine does not start after repeated attempts, go to

VanguardEngines.com or call 1-800-999-9333 (in USA).

WARNING:

Rapid retraction of the starter cord (kickback) will pull your

hand and arm toward the engine faster than you can let go. Broken bones, fractures,

bruises or sprains could result. When starting engine, pull the starter cord slowly until

resistance is felt and then pull rapidly to avoid kickback.

9. Electric Start: Turn the electric start switch (D) to the on/start position.

Note: If the engine does not start after repeated attempts, go to

VanguardEngines.com or call 1-800-999-9333 (in USA).

NOTICE: To extend the life of the starter, use short starting cycles (five seconds

maximum). Wait one minute between starting cycles.

10. As the engine warms up, move the choke control (C) to the run

position.

How To Stop The Engine - Figure 4

WARNING

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

x

Do not choke the carburetor to stop engine.

1. With the throttle control (B) in the slow

position, turn the key switch (D) to the

off position (Figure 4). Remove the key and keep in a safe place out of the reach of

children.

2. Push the stop switch (F) to the off position.

3. After the engine stops, turn the fuel shut-off valve (A), if equipped, to the closed

position.

Maintenance

We recommend that you see any Briggs & Stratton Authorized Dealer for all

maintenance and service of the engine and engine parts.

NOTICE: All the components used to build this engine must remain in place for proper

operation.

WARNING:

When performing maintenance that requires the unit to be

tipped, the fuel tank must be empty or fuel can leak out and result in a fire or

explosion.

Emissions Control

Maintenance, replacement, or repair of the emissions control devices and systems

may be performed by any non-road engine repair establishment or individual.

However, to obtain “no charge” emissions control service, the work must be performed

by a factory authorized dealer. See the Emissions Warranty.

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic

amputation, or laceration.

Fire hazard

WARNING

Before performing adjustments or repairs:

x

Disconnect the spark plug wire and keep it away from the spark plug.

x

Disconnect battery at negative terminal (only engines with electric start.)

x

Use only correct tools.

x

Do not tamper with governor spring, links or other parts to increase engine

speed.

x

Replacement parts must be of the same design and installed in the same

position as the original parts. Other parts may not perform as well, may damage

the unit, and may result in injury.

x

Do not strike the flywheel with a hammer or hard object because the flywheel

may later shatter during operation.

When testing for spark:

x

Use approved spark plug tester.

x

Do not check for spark with spark plug removed.

Maintenance Chart

First 5 Hours

x

Change oil

Every 8 Hours or Daily

x

Check engine oil level

x

Clean area around muffler and controls

Every 100 Hours or Annually

x

Clean or change air filter *

x

Clean pre-cleaner (if equipped) *

x

Change engine oil and filter

x

Replace spark plug

x

Check muffler and spark arrester

Every 250 Hours or Annually

x

Check valve clearance. Adjust if necessary.

Every 400 Hours or Annually

x

Change air filter

x

Replace fuel filter

x

Clean air cooling system *

x

Clean oil cooler fins *

*

In dusty conditions or when airborne debris is present, clean more often.

Carburetor Adjustment

Never make adjustments to the carburetor. The carburetor was set at the factory to

operate efficiently under most conditions. However, if adjustments are required, see a

Briggs & Stratton Authorized Dealer for service.

NOTICE: The manufacturer of the equipment on which this engine is installed specifies

the top speed at which the engine will be operated. Do not exceed this speed.