Engine care – Winco WC6000HE/D User Manual

Page 11

11

3041-00

60706-35

WARNING: PERSONAL DANGER

The 4 wire receptacle on this generator is protected

by a GFCI breaker. This means that connecting the

generator to a distribution panel that has a neutral to

ground bond it will cause the GFCI breaker to trip.

If you are going to wire this generator into a Tem

Power application the neutral to ground bond must be

removed.

1. These engine generator sets are designed for

portable heavy duty commercial use. Receptacles

are provided on the control panel to permit 10 and

40 volt portable appliances and tools to be plugged

directly into them. A 4-wire receptacle (two hot, one

ground, and one neutral) has been provided on the

control panel for use in temporary power applications

requiring 10/40 volt power. Consult a licensed

electrician for wiring the Tem Power plug and con-

necting it as temporary service.

To connect these units directly to an un-powered,

isolated construction site Tem Power panel, have

your electrician connect to the control panel using a

120/240 volt, 4-wire twist-lock plug (L14-30P).

. These generator sets are not designed to be con-

nected existing distribution system. Because existing

distribution system have a neutral to ground bond,

connecting to them through the GFCI protected

L14-30 plug will cause the circuit breaker to trip.

CAUTION: EQUIPMENT DAMAGE

When using these generators to power home

loads or construction trailer, the Conserv-r®

switch must be left in the off position. Some ap-

pliances have such a low current draw (less than

5 to 10 watts) they will not turn the conserver off,

resulting in low voltage being supplied to them.

This low voltage can do permanent damage to

these appliances.

CAUTION: EQUIPMENT DAMAGE

Failure to properly limit and balance the load ap-

plied to the generator will cause the generator to

produce low voltage and may damage the engine

generator set. It may also cause severe damage to

the loads connected to the generator at that time. Im-

proper loading of the generator set constitutes abuse

and will not be covered by warranty.

ENGINE CARE

If major engine service or repair is required, contact

an authorized engine service center. The manufac-

turer of these engines has established an excellent

world-wide engine service organization. Engine ser-

vice is very likely available from a nearby authorized

dealer or distributor. Check the yellow pages of your

local telephone directory under “Engines-Gasoline”

for the closest engine repair center or ask the dealer

from whom you purchased the power plant.

1.

Change the oil after the first 20 hours of opera-

tion and yearly or 100 hours thereafter under normal

operating conditions. Change engine oil every 50

hours of operation if the engine is operated under

heavy load, or in high ambient temperatures.

a. Start the engine and warm it up, stop the engine

and remove the spark plug wire to prevent it

from accidently being started.

b. Remove oil drain bolt at base of the engine

and drain the oil into an approved container.

c. Replace oil drain bolt making sure the sealing

washer is in place..

d. With the engine in a level position, fill with new

oil. Refer to the table on page 5 for the proper

grade of oil.

ENGLISH

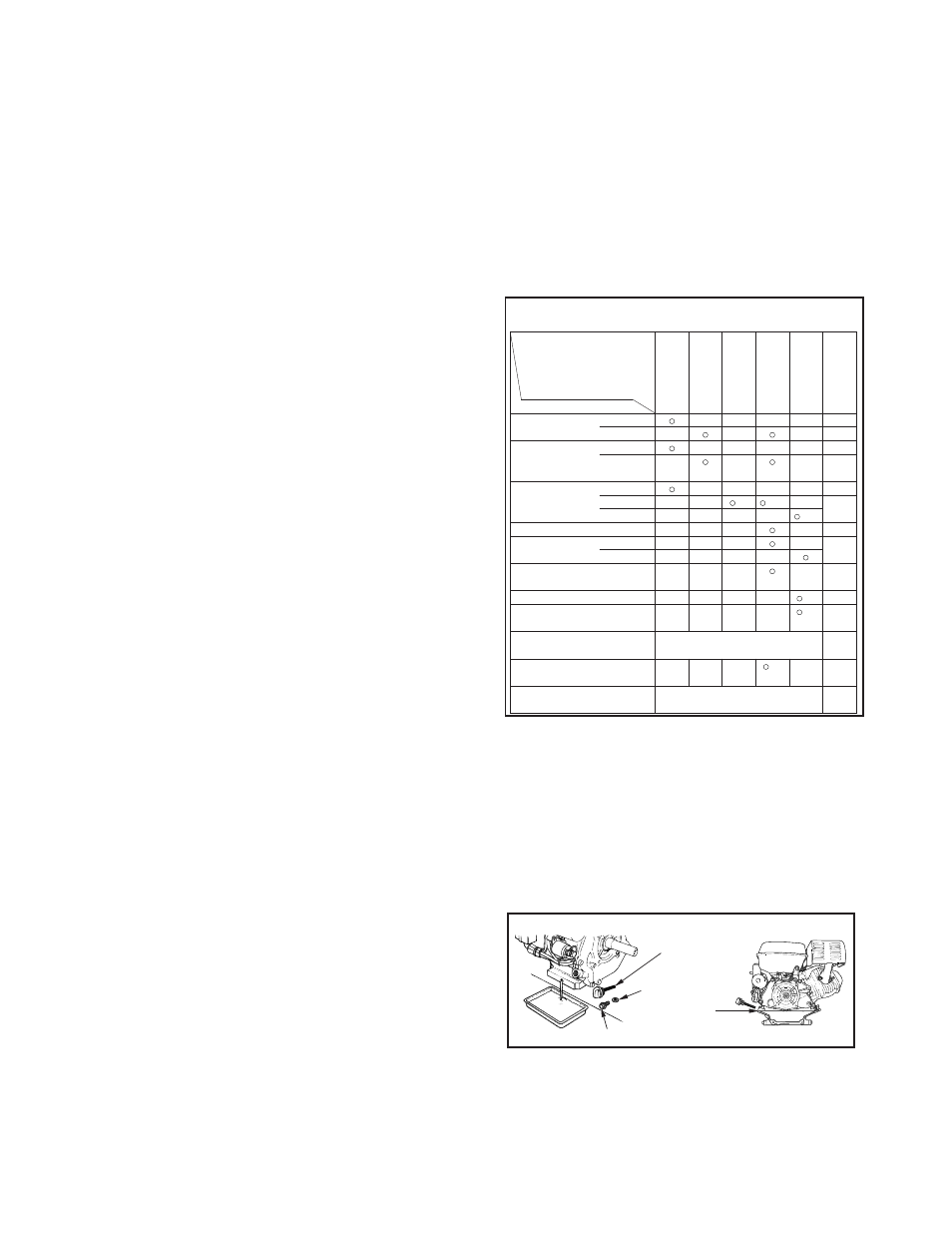

MAINTENANCE SCHEDULE

THE IMPORTANCE OF MAINTENANCE

Maintenance, replacement, or repair of the emission control

devices and systems may be performed by any engine repair

establishment or individual, using parts that are ‘‘certified’’ to

EPA standards.

MAINTENANCE SAFETY

Injury from moving parts.

Burns from hot parts.

Carbon monoxide poisoning from engine exhaust.

SAFETY PRECAUTIONS

SERVICING YOUR ENGINE

TUBE CLIP

BREATHER TUBE

BREATHER TUBE

INTERNAL VENT

CARBURETOR TYPE

STANDARD TYPE

7

Improper maintenance, or failure to correct a

problem before operation, can cause a malfunction in

which you can be seriously hurt or killed.

Always follow the inspection and maintenance

recommendations and schedules in this owner’s

manual.

To help you properly care for your engine, the following pages

include a maintenance schedule, routine inspection procedures,

and simple maintenance procedures using basic hand tools. Other

service tasks that are more difficult, or require special tools, are

best handled by professionals and are normally performed by a

Honda technician or other qualified mechanic.

The maintenance schedule applies to normal operating conditions.

If you operate your engine under severe conditions, such as

sustained high-load or high-temperature operation, or use in

unusually wet or dusty conditions, consult your servicing dealer

for recommendations applicable to your individual needs and use.

Some of the most important safety precautions follow. However,

we cannot warn you of every conceivable hazard that can arise in

performing maintenance. Only you can decide whether or not you

should perform a given task.

To ensure the best quality and reliability, use only new genuine

Honda parts or their equivalents for repair and replacement.

Remember that an authorized Honda servicing dealer knows your

engine best and is fully equipped to maintain and repair it.

To reduce the possibility of fire or explosion, be careful when

working around gasoline. Use only a nonflammable solvent, not

gasoline, to clean parts. Keep cigarettes, sparks and flames

away from all fuel related parts.

Read the instructions before you begin, and make sure you have

the tools and skills required.

Do not run the engine unless instructed to do so.

Let the engine and exhaust system cool before touching.

Be sure there is adequate ventilation whenever you operate

the engine.

Make sure the engine is off before you begin any maintenance

or repairs. This will eliminate several potential hazards:

Failure to properly follow maintenance instructions

and precautions can cause you to be seriously hurt or

killed.

Always follow the procedures and precautions in this

owner’s manual.

Internal vent carburetor with dual element type only.

Cyclone type every 6 months or 150 hours.

Replace paper element type only.

Cyclone type every 2 years or 600 hours.

These items should be serviced by your servicing dealer,

unless you have the proper tools and are mechanically

proficient. Refer to Honda shop manual for service procedures.

Service more frequently when used in dusty areas.

For commercial use, log hours of operation to determine

proper maintenance intervals.

Failure to follow this maintenance schedule could result in non-

warrantable failures.

Good maintenance is essential for safe, economical and trouble-

free operation. It will also help reduce pollution.

(1)

(2)

(3)

REGULAR SERVICE PERIOD (3)

ITEM

Perform at every

indicated month or

operating hour interval,

whichever comes first.

Check level

Change

Check level

Change

Check

Clean

Replace

Clean

Check-adjust

Replace

Clean

Check-adjust

Check-adjust

Clean

Clean

Check

Each

Use

First

Month

or

20 Hrs

Every 3

Months

or

50 Hrs

(1)

Every 6

Months

or

100 Hrs

(1)

(2)

Every

Year

or

300 Hrs

(2)

(2)

After every 500 Hrs. (2)

Every 2 years

(Replace if necessary) (2)

Engine oil

Reduction case

oil

(

)

Air filter

Sediment cup

Spark plug

Spark arrester

(

)

Idle speed

Valve clearance

Combustion

chamber

Fuel tank &

filter

Fuel tube

Refer

to

Page

9

9

9

10

10

10

11

12

12

13

13

Shop

manual

Shop

manual

Shop

manual

Shop

manual

applicable types

applicable types

ENGLISH

REDUCTION CASE OIL (applicable types)

Recommended Oil

Oil Level Check

Oil Level Check

2 : 1 Reduction Case With Centrifugal Clutch

Oil Change

WASHER

OIL LEVEL

DRAIN PLUG

OIL FILLER CAP/

DIPSTICK

UPPER LIMIT

OIL FILLER CAP/DIPSTICK

LOWER LIMIT

OIL FILL HOLE

(bottom edge)

LOWER LIMIT

UPPER LIMIT

OIL FILLER CAP/DIPSTICK

9

Install the oil filler cap/dipstick and tighten securely.

Use the same oil that is recommended for the engine (see page

).

Check the reduction case oil level with the engine stopped and in a

level position.

Remove the oil filler cap/dipstick and wipe it clean.

Insert and remove the oil filler cap/dipstick without screwing it

into the filler hole. Check the oil level shown on the oil filler cap/

dipstick.

If the oil level is low, add the recommended oil to reach the

upper limit mark on the dipstick.

Screw in the oil filler cap/dipstick and tighten securely.

Check the engine oil level with the engine stopped and in a level

position.

Remove the oil filler cap/dipstick and wipe it clean.

Insert the oil filler cap/dipstick into the oil filler neck as shown,

but do not screw it in, then remove it to check the oil level.

Reinstall the oil filler cap/dipstick.

If the oil level is near or below the lower limit mark on the

dipstick, fill with the recommended oil (see page

) to the

upper limit mark (bottom edge of the oil fill hole). Do not overfill.

Running the engine with a low oil level can cause engine damage.

This type of damage is not covered by the Distributor’s Limited

Warranty.

The Oil Alert system (applicable types) will automatically stop

the engine before the oil level falls below the safe limit.

However, to avoid the inconvenience of an unexpected

shutdown, fill to the upper limit, and check the oil level regularly.

Running the engine with a low oil level can cause engine

damage. This type of damage is not covered by the Distributor’s

Limited Warranty.

With the engine in a level position, fill with the recommended oil

(see page

) to the upper limit mark (bottom edge of the oil fill

hole) on the dipstick.

Please dispose of used motor oil in a manner that is compatible

with the environment. We suggest you take used oil in a sealed

container to your local recycling center or service station for

reclamation. Do not throw it in the trash, pour it on the ground,

or pour it down a drain.

Allow the used oil to drain completely, then reinstall the oil drain

plug and new washer, and tighten the oil drain plug securely.

Place a suitable container below the engine to catch the used oil,

then remove the oil filler cap/dipstick, oil drain plug and washer.

Drain the used oil when the engine is warm. Warm oil drains

quickly and completely.

The Oil Alert system (applicable types) will automatically stop the

engine before the oil level falls below the safe limit. However, to

avoid the inconvenience of an unexpected shutdown, always

check the engine oil level before startup.

1.

2.

3.

4.

3.

4.

1.

2.

1.

2.

3.

4.

8

8

8