Locating stove – Vogelzang VG650ELG User Manual

Page 6

Page 6

| VG650ELG MountainEEr™

www

.vogelzang.com

VGZ-025 | 20120424.0

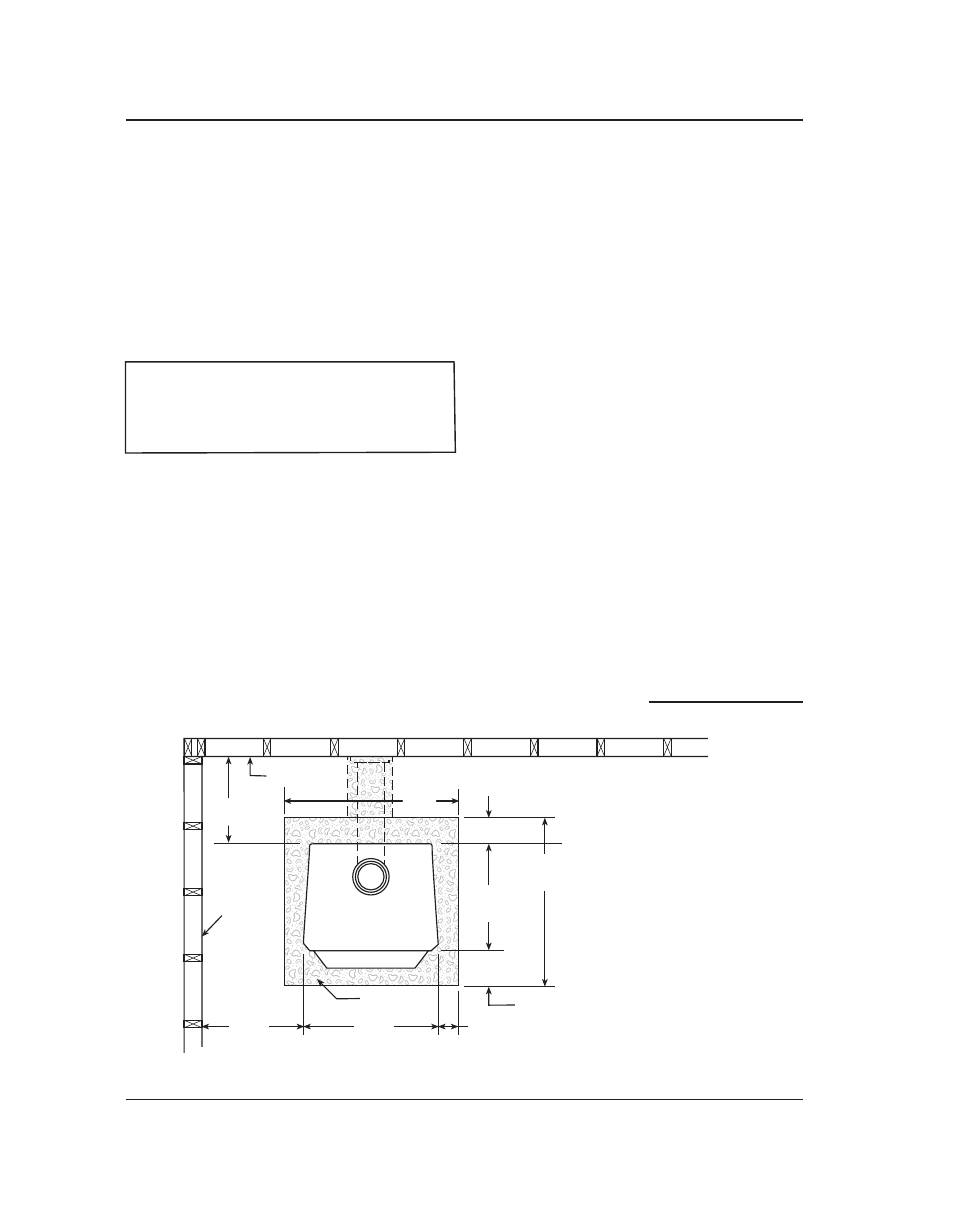

lOCATINg STOvE

1. The stove must be placed on solid concrete,

solid masonry, or when installed on a combus-

tible floor, on a listed UL 1618 Type 2 floor

protector, such as Hy-C or Imperial Model

UL4848BK or equivalent with 1.0 R-factor.

(NOTE: to calculate R-value of alternative

materials see page 20). The base must extend

at least 16˝ beyond the front of the access door,

8˝ to the sides, 8˝ behind and must extend

under and 2 inches beyond either side of the

stove pipe if it is elbowed towards a wall. (See

figures 7 & 9 and consult local building codes

and fire protection ordinances.)

CAUTION: (FIRE hAzARD) CARPETING AND

OThER COMBUSTIBLE MATERIAL MUST NOT

COVER ThE FLOOR PROTECTOR. ThESE

MATERIALS MUST REMAIN OUTSIDE OF

COMBUSTIBLE CLEARANCES, SEE FIG. 7– 9.

2. The stove must have its own flue.

DO NOT

CONNECT ThIS UNIT TO A ChIMNEY

FLUE SERVING OThER APPLIANCES.

3. After observing the clearances to combus-

tible materials (figures 7–9), locate your floor

protector accordingly (figure 7) and care-

fully place the stove in your selected location.

Install connector pipe, elbows, and thimble as

required, utilizing either a recently cleaned and

inspected 6” masonry chimney or a 6” i.d. UL

103 HT listed chimney.

4. Use round 6” dia., minimum 24 MSG (mini-

Fig. 7 – TOP VIEw Minimum Clearance Dimensions from Combustible Surfaces

FLOOR

PROTECTOR

DASHED LINES SHOW HORIZONTAL CHIMNEY CONNECTOR

AND ADDITIONAL FLOOR PROTECTOR REQUIRED BENEATH

AND EXTENDING 2” BEYOUND EACH SIDE

COMBUSTIBLE CONSTRUCTION IN ACCORDANCE WITH NFPA 211

BACKWALL

SIDEWALL

8"min.

17"

48"

16"min.

8"min.

28"

25"

min.

26"min

MINIMUM CLEARANCES TOP VIEW

44"

Volgelzang

VG650

Use 48"x 48"

Standard Size

Floor Protector

mum standard gauge) black or 26 MSG blue

steel stove pipe. DO NOT use galvanized stove

pipe. Secure pipe/elbow sections with three

sheet metal screws at each joint to make the

piping rigid. Screws may be no more than a

maximum of 3˝/76mm apart.

DO NOT CON-

NECT ThIS STOVE TO ANY AIR DISTRI-

BUTION OR DUCT SYSTEM.

5. Recheck clearances from the stove, con-

nector stove pipe, and corner clearances

using the illustrations in figures 7–9 and

your local building codes or fire protection

ordinances.

NOTE: A wALL FACED wITh DRYwALL, BRICk

OR STONE MUST BE CONSIDERED A COMBUS-

TIBLE SURFACE.

6.

Do Not iNstall this stove iN a mobile

home, maNufactureD home, teNt or

trailer

– NO EXCEpTIONS!

(HUD Federal

Standard: 24 CFR Ch.xx)

7. The clearances provided are minimum

dimensions determined by US Test Standard UL

1488-1996, tested and applied by Intertek Test-

ing Services, the manufacturer’s testing labora-

tory. Installation of this stove must comply with

the latest edition of NFPA 211 for reduced clear-

ances and/or your local building code rulings.

Use whichever minimum dimensions are

LARGEST.

8. This stove meets U.S. Test Standard:

UL 1482-1996.

continued on next page