Pre-installation requirements – Vogelzang TR004 User Manual

Page 6

Page 6

| TR004 COLONIAL™

TR004M | 11102010.0

PRE-INSTAllATION REqUIREmENTS

FIREPLACE CONDITION &

ZERO CLEARANCE REqUIREmENTS

A masonry fireplace must meet minimum code

requirements, National Fire Protection Association,

(NFPA) 211, or the equivalent for a safe installation.

Contact a professional, licensed installer, your local

building inspector or the local fire authority for the

requirements in your area. Your insurance company

should be able to recommend a quallified inspector.

Inspections should include the following:

1.

Condition of the fireplace and chimney. A mason-

ry fireplace and chimney MUST be inspected prior

to installation of this insert. They must be free from

cracks, loose mortar, creosote deposits, blockage

or other evidence of deterioration. If found, these

items MUST be repaired prior to installation. DO

NOT REMOVE BRICKS or MORTAR from existing

fireplace when installing this unit.

2.

Chimney Size. Minimum chimney size is 6˝

(152mm) diameter. Maintain a 15 ft. minimum overall

chimney height measured from the top of appliance

to the top of the chimney. Chimneys must extend at

least 3 ft. above the roof and at least 2 ft. above the

highest point within 10 ft. of the chimney top. See

the Chimney Connections section of this manual.

2.

Zero Clearance or metal Heatform Fireplaces.

These fireplaces and chimneys must meet the

minimum code specifications as noted above. Fac-

tory built zero clearance fireplaces must be listed

and suitable for solid fuel use. Chimneys must be

at least 7 inch diameter to accomodate a required,

continuous, stainless steel liner from the insert flue

collar to the top termination of the chimney.

Only detachable parts that can be easily replaced

(i.e. damper parts, screens, doors and side and

back refractory panels) are to be removed. These

parts must be stored and readily available for re-

placement if the insert is ever removed. The removal

of any parts that render the fireplace unusable for

burning solid fuel requires a permanent label to be

affixed by the installer that states the fireplace is

unsuitable for burning solid fuel unless the missing

parts are replaced and the fireplace is restored to

its original, certified condition.

3.

Chimney Caps. Mesh type chimney caps and spark

arrestors must be able to be removed for regular

inspection and cleaning. Otherwise the mesh should

be removed to prevent possible plugging. Check

your local fire and building codes.

4.

Chimney Liner. The chimney must be suitable for

burning solid fuel. Install a continuous stainless

steel liner from the flue collar of the appliance to

the top of the chimney. Liner must be UL Listed to

UL1777.

5.

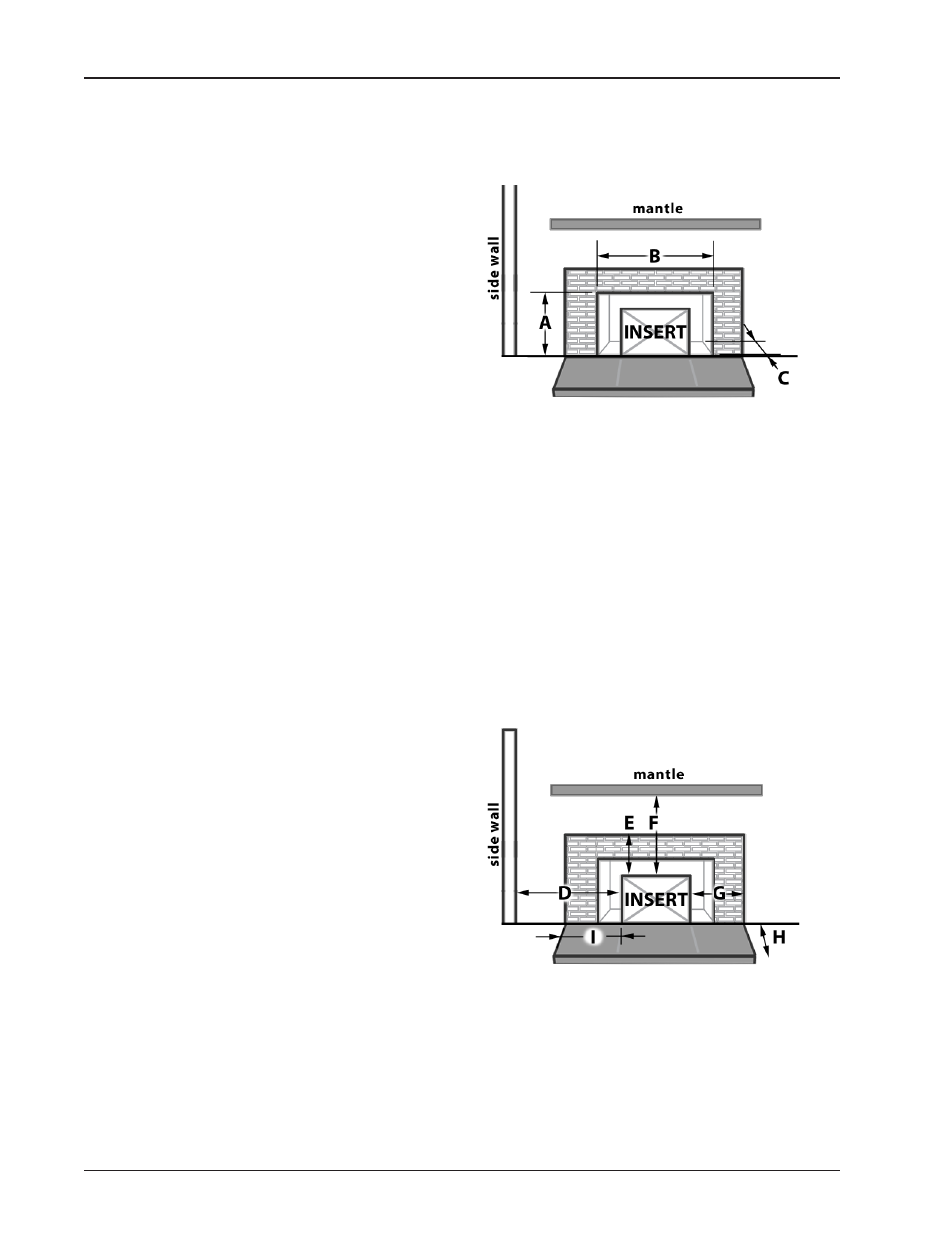

Fireplace Opening Dimensions.

A. Minimum Height ..........23˝

B. Minimum Widths ..........29˝

C. Minimum Depth ...........14˝

7.

makeup Air Requirements. This insert requires an

adequate supply of makeup air to operate safely

and efficiently. In some areas, this is a building code

requirement. Inadequate air supply will cause poor

combustion, inefficient operation, creosote buildup,

back drafting and smoke puffing into the living ar-

eas. If any of the following conditions are evident,

a makeup air supply MUST be installed.

Figure 1 Minimum Opening Specifications

6.

Combustible material Clearances. The fireplace

and chimney must be inspected to make sure there

is adequate clearance to combustible materials.

This includes the top, side, front and back as well as

concealed combustibles in the chimney and mantle

areas. Your local building inspector or fire authority

should have information on whether older fireplace

meet current codes and are suitable for use. See

also figure 1 and figure 2.

D. Min. Distance to Sidewall ........12˝

E. Min. Distance to Top Trim ........15˝

F. Min. Distance to Mantle ..........21.75˝

G. Min. Distance to Side Trim ......9.5˝

H. Min. Floor Protector Front .......24˝

I. Min. Floor Protector Side ........6˝

Figure 2 Minimum Clearance to Combustible Materials