VACUUBRAND RZ 9 User Manual

Page 40

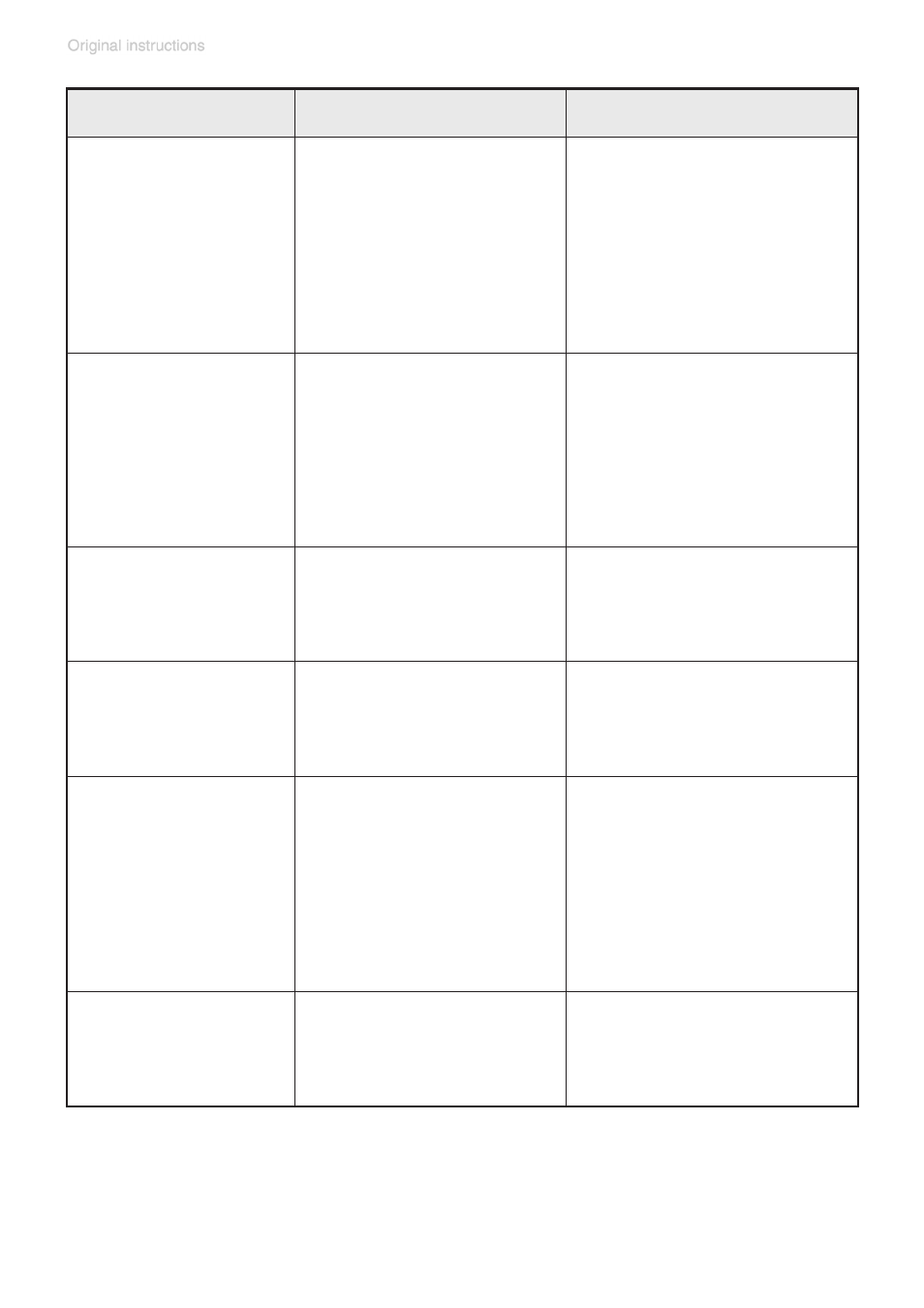

Fault

Possible cause

Remedy

❑ Pump does not

achieve its ultimate

vacuum or usual

pumping speed.

➨ Outgassing substances

or vapor generated in

the process?

✔ Check process parame-

ters.

➨ Inlet blocked?

✔ Open inlet. Ensure that

the inlet line does not be-

come blocked.

➨ None of the above

mentioned causes?

✔ Contact local distributor.

❑ Pump too noisy or

strange noise.

➨ Too much oil?

✔ Lower oil level to mark

”max.”.

➨ Loud exhaust noise?

✔ Connect a hose or as-

semble an oil mist filter at

the outlet.

➨ None of the above

mentioned causes?

✔ Contact local distributor.

❑ Oil in the inlet line. ➨ Back diffusion (small

amount of oil, oil film)?

✔ Install a sorption trap or a

separator, if necessary.

➨ Back streaming (large

amount of oil)?

✔ Contact local distributor.

❑ Oil leakage.

➨ Oil spilled?

✔ Absorb the oil and dis-

pose of according to reg-

ulations.

➨ Other cause?

✔ Contact local distributor.

❑ High oil consump-

tion.

➨ High inlet pressure?

✔ Normal. Top up oil when-

ever necessary. Install oil

mist filter at outlet.

➨ Operation with gas bal-

last?

✔ Top up oil whenever nec-

essary. Install oil mist filter

at outlet.

➨ Oil level too high?

✔ Lower oil level to mark

”max.”.

❑ Fast aging of the

oil.

➨ Pumping aggressive

gases?

✔ Use suitable oil.

➨ Condensation in the

pump?

✔ Use separator or cold

trap.

➨

A service manual with exploded view drawings, spare parts list and

directions for repair is available on request.

+

The service manual is intended for trained service people only.