VACUUBRAND PC 620 NT User Manual

Page 46

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999188 / 19/05/2009

* Blips only if in function ”Configuration” sound is set to ”On”.

** VMS: Vacuum Management System to switch a non-VARIO-pump

Attention: All error messages have to be confirmed (deleted) by pressing key START/STOP.

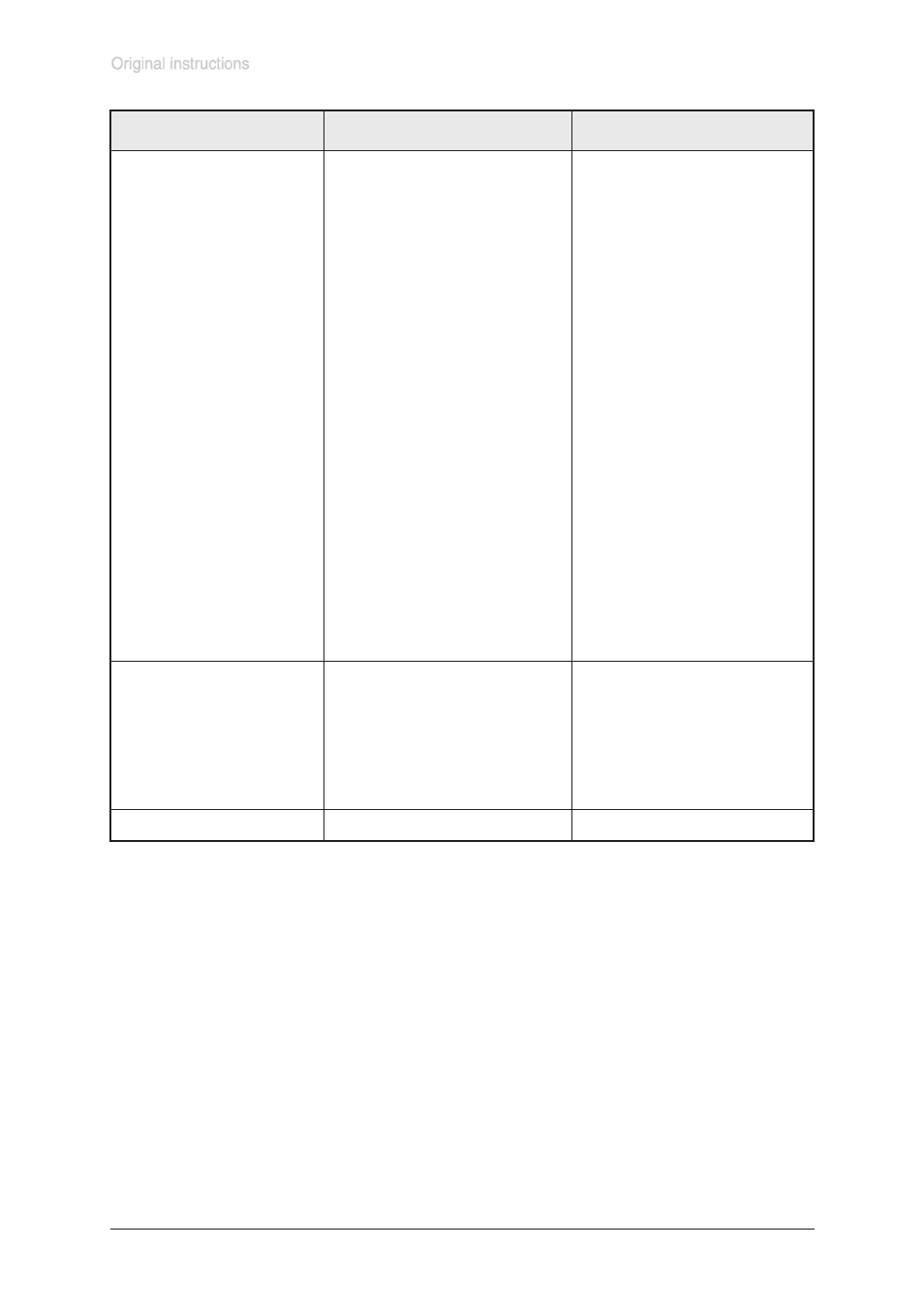

Fault

Possible cause

Remedy

❑ Pump does not achieve

its ultimate vacuum or

usual pumping speed.

➨ Wrong setting at controller?

✔ Choose function ”Pump

down” and check again.

➨ Leak in the pipeline or vacu-

um system?

✔ Check connection, pipeline

and vacuum system.

➨ Long, narrow line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Pump has been exposed to

condensate?

✔ Allow the pump to run for

some minutes with open inlet

port.

➨ Deposits have been formed

inside the pump?

✔ Clean and inspect the pump

heads.

➨ Diaphragms or valves defec-

tive?

✔ Replace diaphragms and/or

valves.

➨ Outgassing substances or

vapour generated in the proc-

ess?

✔ Check process parameters.

➨ Pump too hot?

✔ Allow pump to cool down,

identify and eliminate cause

of failure. Manual reset is

necessary. Switch off pump

or unplug mains.

❑ Pump too noisy.

➨ Loud exhaust noise?

✔ Connect hose or silencer to

pump outlet.

➨ Diaphragm crack or dia-

phragm clamping disc loose?

✔ Perform maintenance.

➨ Other than above mentioned

causes?

✔ Contact local distributor.

❑ Pump seized.

✔ Contact local distributor.