VACUUBRAND PC 600 LAN User Manual

Page 24

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999084 / 05/10/2009

page 24 of 46

non-return valve closed

non-return valve open

Notes: If the system pressure is increasing, the port with the lowest preset pressure is closed at first. At

decreasing system pressure the port with highest preset pressure is opened at first.

Manually controlled vacuum applications:

In general: Avoid parallel processes which differ strongly in their demands concerning pumping speed or

ultimate vacuum as well as their simultaneous operation.

If several manually controlled ports are operated simultaneously, it is recommended to install a flow control,

such that the required process pressures of the applications are just attained. The permanent gas flow

through the hand-controlled ports has the same effect as a leak and leads to an increase of pressure in the

system.

If the pressure in the network exceeds the preset pressure of a parallelly operated application, the non-

return valve of that port closes. Such the application is protected against contamination or backflow, but it

is no longer possible to evacuate or control the application!

Remedial action: Further reduction of gas flow at the manual port is necessary until the system pressure

in the network is decreased below the lowest process pressure of a parallel application.

Automatically controlled vacuum applications:

An increase of system pressure due to formation of gas (e.g. pumping down) and/or programmed preset

pressures can occur if several automatically controlled ports of a vacuum network are operated

simultaneously. Such an increase of pressure usually occurs in form of a pressure peak. Therefore the

vacuum supply of parallelly operated applications is cut off only temporarily; the non-return valves counteract

the mutual interference.

In general: It is recommended to reduce the pumping speed at automatically controlled ports as well using

an additional flow control. By that means pressure bursts on the application side or in the vacuum network

are minimised. The hysteresis (

Δp) at the vacuum controller at the port should not be set too low (Δp=

approx. ±10%p

Set

), if possible use the automatic hysteresis preset at the controller.

Notes: If the system pressure is increasing, the port with the lowest preset pressure is closed at first. At

decreasing system pressure the port with highest preset pressure is opened at first.

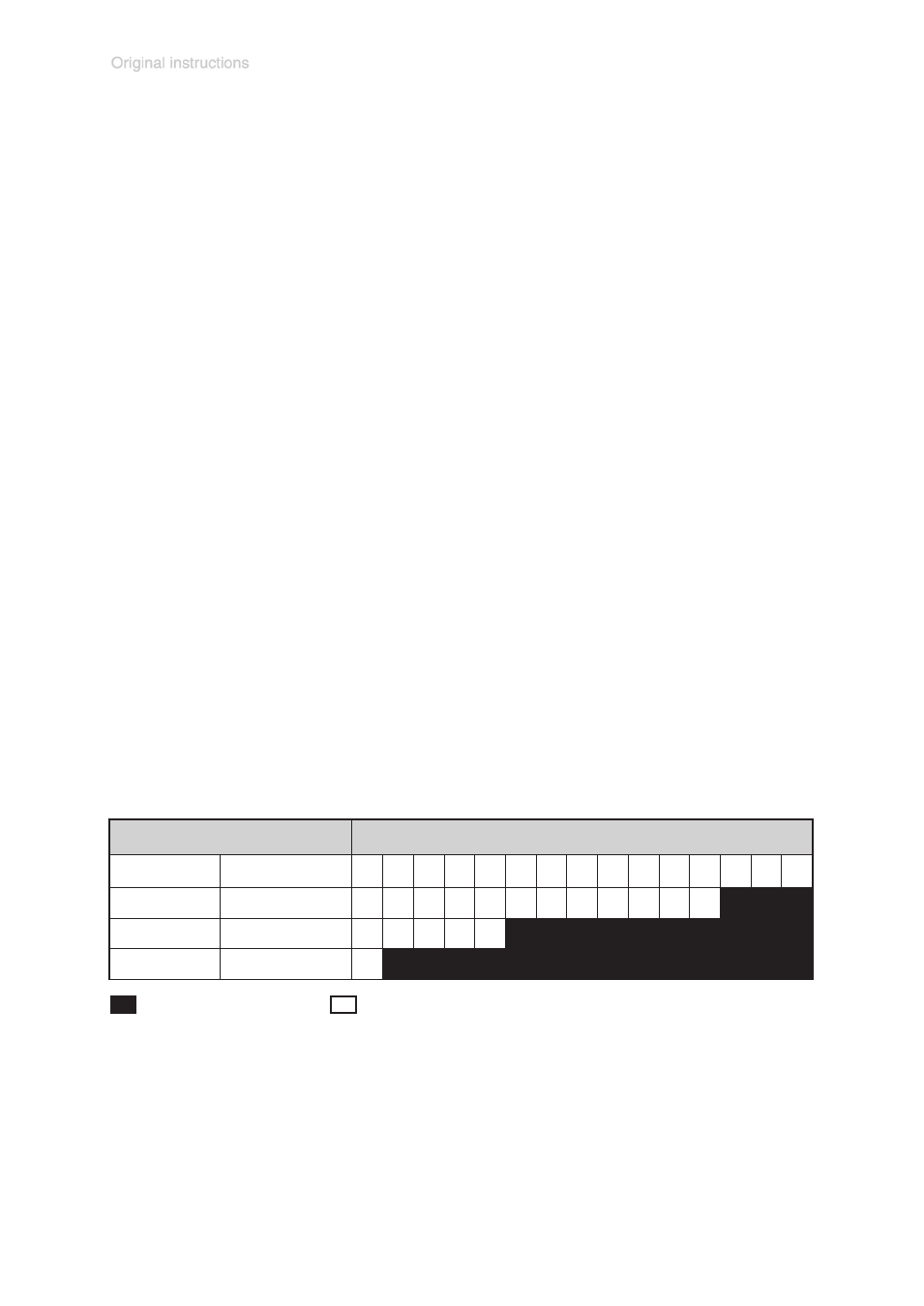

Effect of the integrated non-return valves:

At each port a non-return valve is integrated to avoid an increase of pressure or contamination. The preset

pressures of the different applications are related to the system pressure in the vacuum network as shown

below:

e

v

l

a

v

n

r

u

t

e

r

-

n

o

n

f

o

s

u

t

a

t

s

)

r

a

b

m

(

k

o

w

t

e

n

m

u

u

c

a

v

l

a

c

o

l

n

i

e

r

u

s

s

e

r

p

m

e

t

s

y

s

e

r

u

s

s

e

r

p

t

e

s

e

r

p

)

r

a

b

m

(

0

2

0

4

0

6

0

8

0

0

1

0

2

1

0

4

1

0

6

1

0

8

1

0

0

2

0

2

2

0

4

2

0

6

2

0

8

2

0

0

3

1

n

o

i

t

a

c

i

l

p

p

a

0

5

2

2

n

o

i

t

a

c

i

l

p

p

a

0

0

1

3

n

o

i

t

a

c

i

l

p

p

a

5

3