VACUUBRAND PC 600 LAN User Manual

Page 14

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999084 / 05/10/2009

page 14 of 46

Attention: Important notes regarding the use of gas ballast

☞ Make sure that air/gas inlet through the gas ballast valve never lead to hazardous,

explosive or otherwise dangerous mixtures. If in doubt, use inert gas.

☞ When using air rather than inert gas, risk of significant damage to equipment and/or

facilities, risk of personal injury or even loss of life exists due to the formation of

hazardous and/or explosive mixtures if air and pumped media react inside or at the

outlet of the pump.

For condensable vapours (water vapour, solvents, ...):

☞ Do not pump vapour before pump has reached its operating

temperature and with gas ballast valve closed.

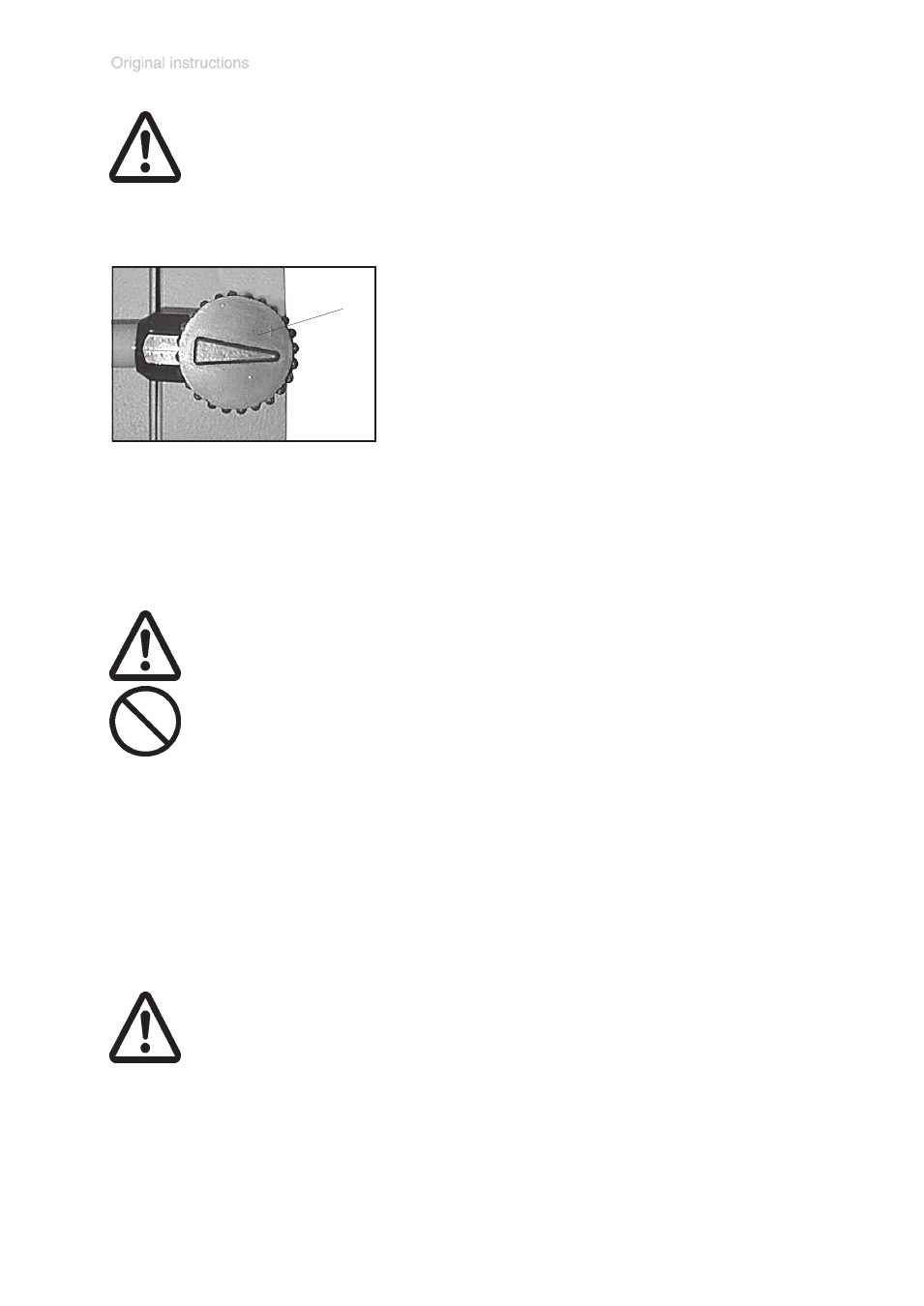

☞ Open gas ballast valve. (Closing of gas ballast valve by turn-

ing 180°.)

☞ The gas ballast valve is open if the arrow on the gas ballast

cap shows away from the pump.

☞ With gas ballast valve open ultimate vacuum will be reduced,

pumping speed is decreased.

☞ Use inert gas at the air inlet to avoid the formation of explo-

sive mixtures.

gas

ballast

In case of low boiling solvents when the formation of condensate is unlikely, the use of

gas ballast might be unnecessary.

☞ Operating the pump without gas ballast increases the solvent recovery rates at the

exhaust waste vapour condenser.

Attention: Notes concerning the operation of the exhaust waste vapour condenser

➨ Check hose connections prior to starting operation of the cooling system.

➨ Check coolant hoses regularly during operation.

☞ Ensure that the coolant outlet pipeline is always free and that it cannot get blocked.

☞ Maximum permissible coolant pressure at the exhaust waste vapour condenser:

6 bar (absolute)

☞ Comply with the maximum permissible coolant pressures of additional components

in the coolant circuit (e.g coolant valve).

☞ Avoid overpressure in the coolant circuit (e.g. caused by blocked or squeezed cool-

ant hoses).

☞ Permissible range of coolant temperature at the exhaust waste vapour condenser:

-15°C to +20°C

☞ The gas outlet (hose nozzle 10 mm) must not be blocked. The exhaust pipeline has

always to be free and pressureless to enable an unhindered discharge of gases.

➨ Check the overpressure safety relief device at the exhaust waste vapour condenser

regularly, replace if necessary. Check especially for sticking and cracks.

☞ Connect the exhaust to a suitable treatment plant to prevent the discharge of dan-

gerous gases and vapours to the surrounding atmosphere.

In case of condensation:

➨ Check liquid level in both catchpots during operation. Avoid overflowing of the catch-

pots.

☞ Do not overfill the catchpots. Maximum liquid level approx. 80%, to avoid problems

when removing the catchpots.

➨ Check liquid level in both catchpots regularely and drain catchpots in time.

Removing the catchpots:

Catchpot at outlet:

➨ Remove joint clip, remove catchpot and drain condensate.