Installation guide, Step 16, Step 15 – Trending Accessibility Transitional & modern linear fusion shower pan surface mounted on subfloor User Manual

Page 6: Step 14

Installation Guide

www.trendingaccessibility.com

6

for linear shower pan surface mounted on subfloor

Step 13

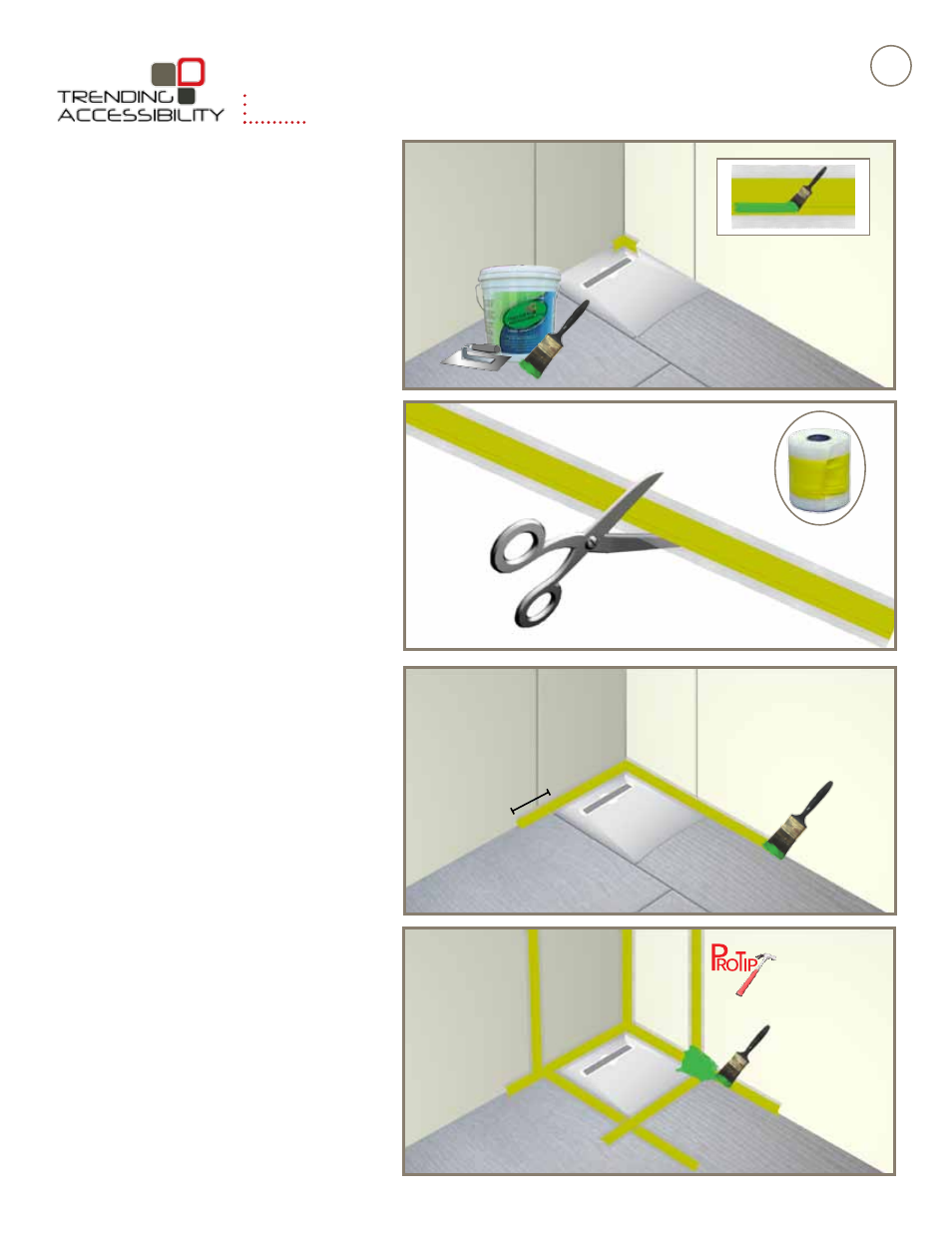

Begin taping the wetroom floor at the interior corners

of the Linear Fusion Pan using the corner pieces of

the crack isolation tape provided. Using a paint brush

or trowel, slather liquid waterproofing into corner,

press piece into place, then apply liquid waterproof-

ing on top. Make sure to smooth out any creases.

Repeat for additional corners.

Step 15

Just like you applied the corner pieces, use your

cut strips of Crack Insulation Tape to cover all the

seams. Again, trowel or paint liquid waterproofing

onto seam, press tape into position and coat the

top to seal. Make sure to fully cover both sides of

the crack isolation tape with the liquid waterproof-

ing product. To make this process more manage-

able, it is best to work in two foot sections.

NOTE:

Illustration just shows tape use.

Please apply liquid waterproof-

ing to the wall and tape before

applying.

Step 14

Using the 5” crack isolation tape provided, cut

strips of tape to length, to cover all seams (Cor-

ner seams, wall/floor seams, pan/floor joint). Put

pieces aside.

If you are creating full wet room, you will need to tape

any seams throughout the entire room.

If you are only waterproofing the shower zone, you

will only need to tape the seams up to 2 feet outside

the shower area.

Step 16

Using the 5” crack isolation tape. Overlap all seams

of cement board used on either the floors or walls.

Overlap the seam where the Linear Fusion pan and

cement board meet.

Make sure the tape

overlaps the seams

equally.

Extend the tape

2 feet past the

shower pan

2 feet