Top Flite TOPQ5700 User Manual

Page 6

with a knife-sharpening stone, then

polish the points with 600-grit

sandpaper followed by rubbing

compound. The smoother the points,

the less friction. However, don’t

sharpen the points too much. Leave a

very small polished radius at the tip.

2. Before using the balancer, spread a

very thin film of oil on the magnet ends.

3.

Check the balancer shaft for

straightness by rolling it slowly on a

piece of clean, dust-free plate glass. If

the shaft it bent, you’ll be able to see

light under the shaft as you roll it on the

glass. If the shaft has any significant

bend, it will not balance accurately.

Straighten the shaft by carefully

bending it. You can check the trueness

of the shaft by placing it on the balancer

without the cones.

4. Balance each individual balancer

cone, one at a time.

5. Your balancer is now ready to be

used for high precision work.

PROPER CARE OF

YOUR BALANCER

•

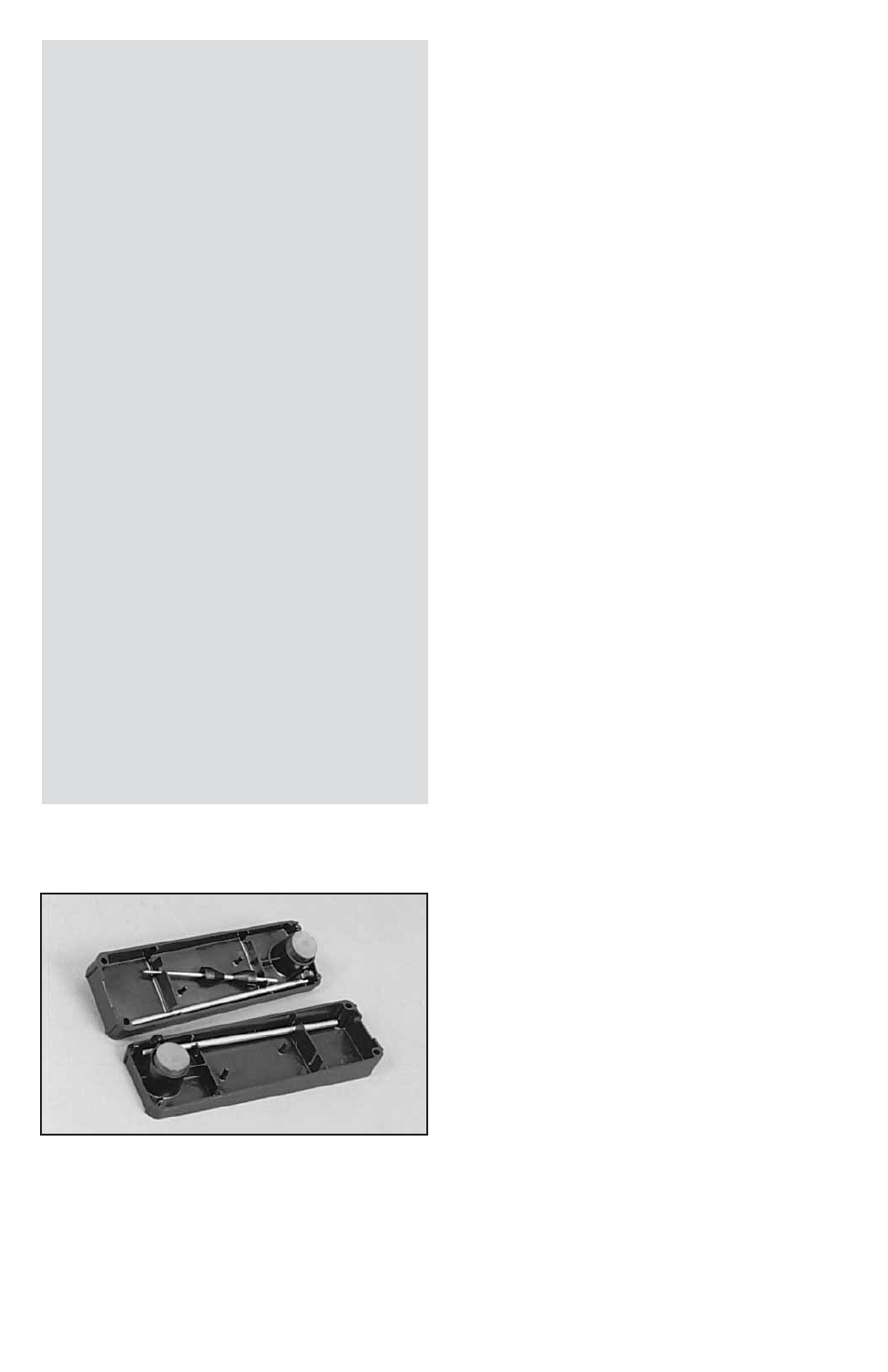

Place all components into the case

halves in the positions shown in the

photo. Press on the ends of the rods

(not in the middle) when storing, to

prevent bending. We recommend

storing one base rod in each case

half, for minimum case distortion.

•

If the balancer parts become exposed

to water, dry them thoroughly. Do not

close the balancer case halves

together with metal parts inside if there

is moisture in the case, as this can

result in corrosion of the metal parts.

•

Do not drop the magnets, or allow the

magnets to snap together. NOTE: If

you should happen to break a magnet,

you may glue the magnet pieces back

together with epoxy or CA glue, with

very little reduction in magnet strength.

•

Handle the balancer shaft with care.

It is made of soft steel (for high

magnetic attraction) which will bend

easily if handled roughly. When

pushing the shaft into the storage

slots in the case, push down near

both ends of the shaft, rather than at

the middle. Also, when removing the

shaft from the case, pull up near the

ends. Don’t let the shaft snap hard

against the magnets, as this will blunt

and deform the shaft ends.

•

When disassembling the balancer,

gently twist the base rods as you pull

them out.

•

Always open the case halves by

popping both ends open with a coin.

Don’t try to force the halves open

from one end only.

•

Do not subject the balancer to high

temperatures, above 120°F (49°C),

such as on the dashboard of a closed

automobile on a hot, sunny day, as

high temperatures may deform the

plastic and permanently reduce the

strength of the magnets.

•

If you need more friction or “holding

power” between the shaft and the cones

(for balancing heavy objects), try

cleaning the shaft with rubbing alcohol

or solvent. If you still need additional

friction, try roughening the plated surface

of the shaft with 320-grit sandpaper.