Slant/Fin Gas Conversion Field User Manual

Page 20

GAS RATE TABLE

Cubic Feet

Boiler rated input

Gas Consumption

cu. ft./hr. of 1000 Btu/cu. ft.

1000 Btu/cu.ft. gas, in 3

Natural Gas

minutes, at rated input

33

1.65

34

1.70

60

3.00

70

3.50

75

3.75

90

4.50

100

5.00

105

5.25

120

6.00

125

6.25

140

7.00

150

7.50

175

8.75

180

9.00

200

10.00

210

10.50

225

11.25

245

12.25

250

12.50

275

13.75

300

15.00

325

16.25

350

17.50

375

18.75

399

19.95

The gas metered in 3 minutes to obtain rated input for each boiler

model using 1000 Btu/cu.ft. gas is tabulated in the gas rate table.

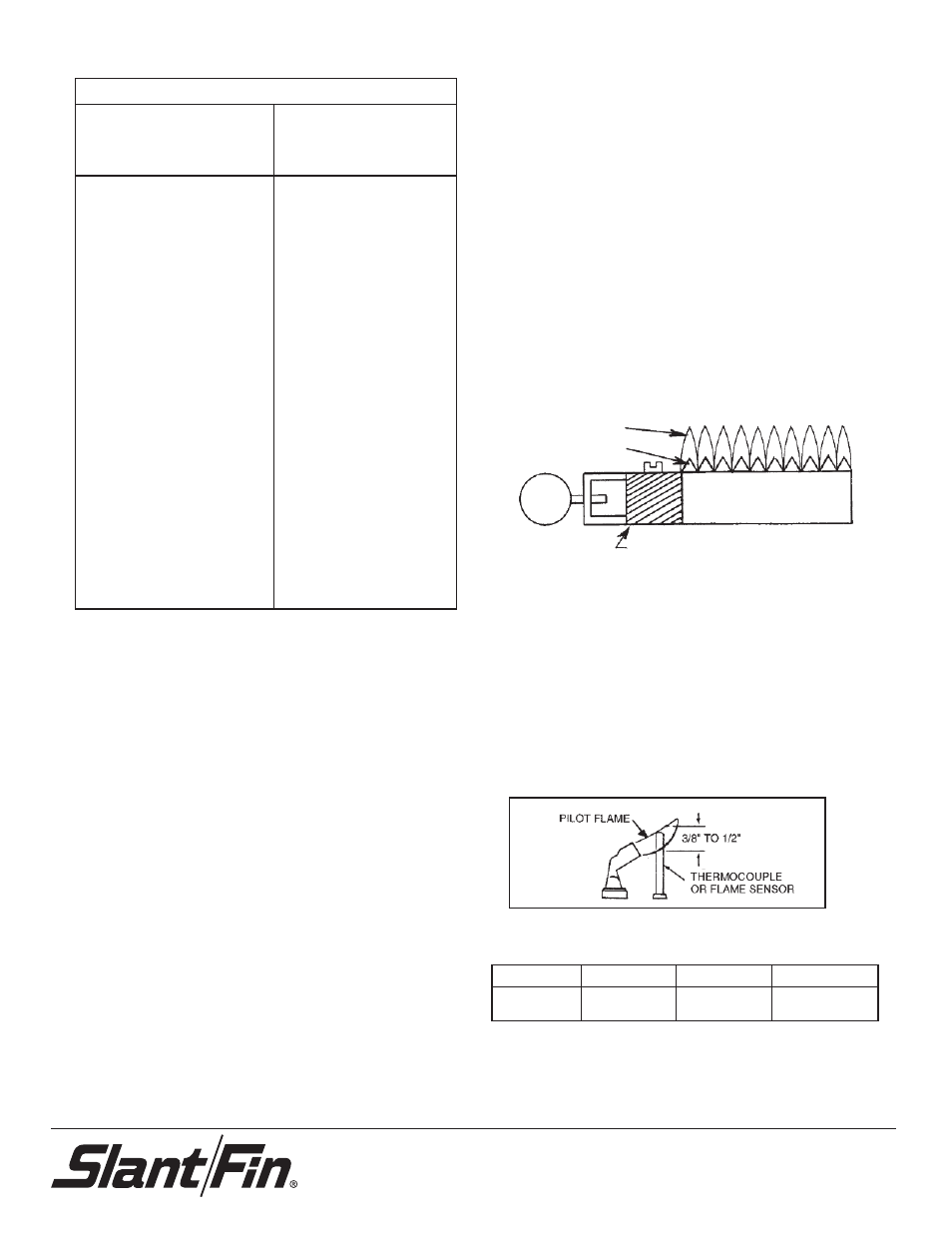

B. Main Burner

1. Fire the boiler continuously for at least 15 minutes,

to reach burner operating temperature.

2. Observe the flames, all burners. The base of all

flame jets should be blue. The tips should be blue

shading to orange.

NOTE: Dust, disturbed by any movement, will

cause bright orange flames. Wait for dust to settle.

3. For one burner, close the air shutter until some of

its flame jet tips turn yellow-white, indicating insuf-

ficient primary air. Then open shutter until whitish

tips disappear completely. Set all burner shutters

to the same opening. Observe to make sure that

no yellow-white tips appear over any portion of

the flame. Small yellow tips at the pilot location are

permitted.

NOTE: This adjustment method gives MINIMUM

primary air setting for safe combustion. DO NOT

attempt to make this adjustment unless burners

are at operating temperature. Adjustment should

be made with burner access panel in final operat-

ing position. Use of a mirror may be helpful to

observe flames. Note that burner ports are on top

of main burner tube.

C.Main Burner Ignition Checkout and Pilot Adjustment

1. The pilot flame must not smother or snuff out

when tested as follows:

a. Main burner ignition from cold start-repeat.

b. Continued operation of main burner.

c. Main burner ignition with appliance at maxi

mum operating temperature after prolonged

operation.

NOTE: Observe operation of the pilot burner with

appliance doors in the final operating position.

Use of a mirror may be helpful.

2. Safety Shutdown Checkout

a. For proper operation the pilot should engulf the

thermocouple or flame sensor as shown below.

b. To adjust pilot, turn pilot flow adjustment screw

on valve clockwise or counterclockwise to give

a steady flame enveloping 3/8" to 1/2" inch of

the tip of the thermocouple or flame sensor.

Note that turning the pilot adjustment screw

clockwise will decrease the pilot flame.

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin

LTD/LTEE

, Mississauga, Ontario

www.slantfin.com

Main Burner

Flame Tips

Blue Flame Base

Front-back sliding primary air

shutter locking screw on top.

Manifold

Gas

Manifold

Minimum Inlet

Maximum Inlet

Natural Gas

3.5”

5”

11”

LP Propane

9.5”

11”

14”

Gas Pressure (inches of wc)