Wiring the led outputs, Dry contact wiring, Setting dip switches – SilentKnight 5880 LED Driver Module User Manual

Page 2

5880 LED I/O Module Installation Instructions

2

© 2008 Honeywell International Inc. PN 150972 Rev C

Wiring the LED Outputs

The 5880 has four 12-pin connectors (P/N

130092) used to connect LEDs. All LED outputs

use a common pin on each connector for LED

power (see Figure 3). Current is limited through

each output so no series resistor is required.

On connector P1, pin 12 is an open collector

output for controlling a piezo (PZT) output. This

output matches the piezo output pattern of the

FACP on-board annunciator.

Note: The open collector PZT output does not have a built-in

current limiting resistor, one is required to limit the max.

sink current (see Specifications for max sink current). The

PZT output is not mappable.

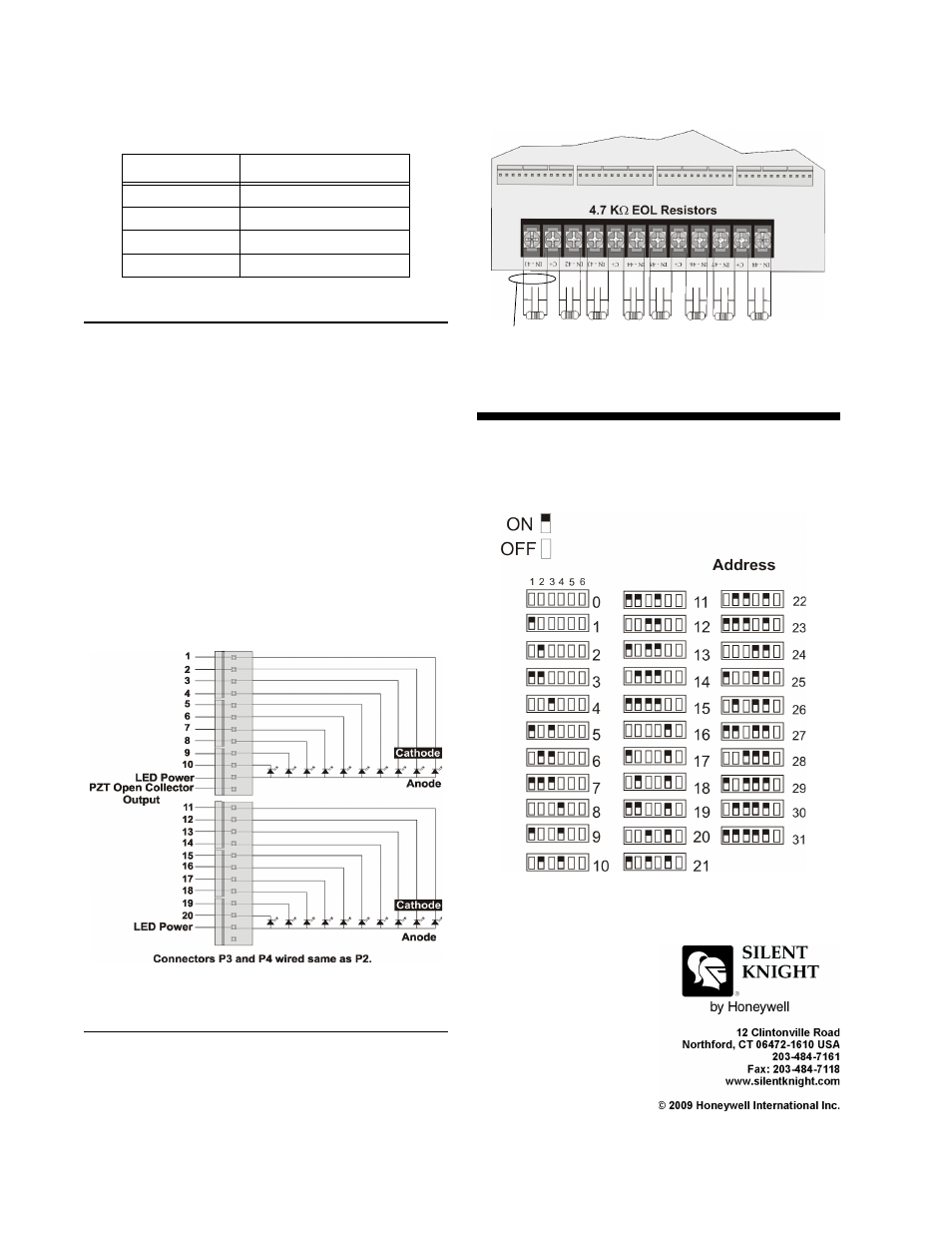

Wire the LED outputs as shown in Figure 3.

Figure 3: 5880 LED Outputs

Dry Contact Wiring

The 5880 has eight input circuits used to monitor

switch inputs such as pull stations, water flow,

tamper, reset, or silence type switches. Wire

contacts as shown in Figure 4.

Figure 4: Dry Contact Wiring

Setting DIP Switches

Each 5880 requires a unique ID number which is

set using the DIP switches on the 5880 circuit

board. See Figure 5 for DIP switch settings.

Figure 5: DIP Switch Settings

Table 2: 5880 to FACP Connections

5880 Terminals

FACP Terminals

B

B

A

A

S+

+

S-

–

P1

P2

All Inputs Supervised/Power Limited