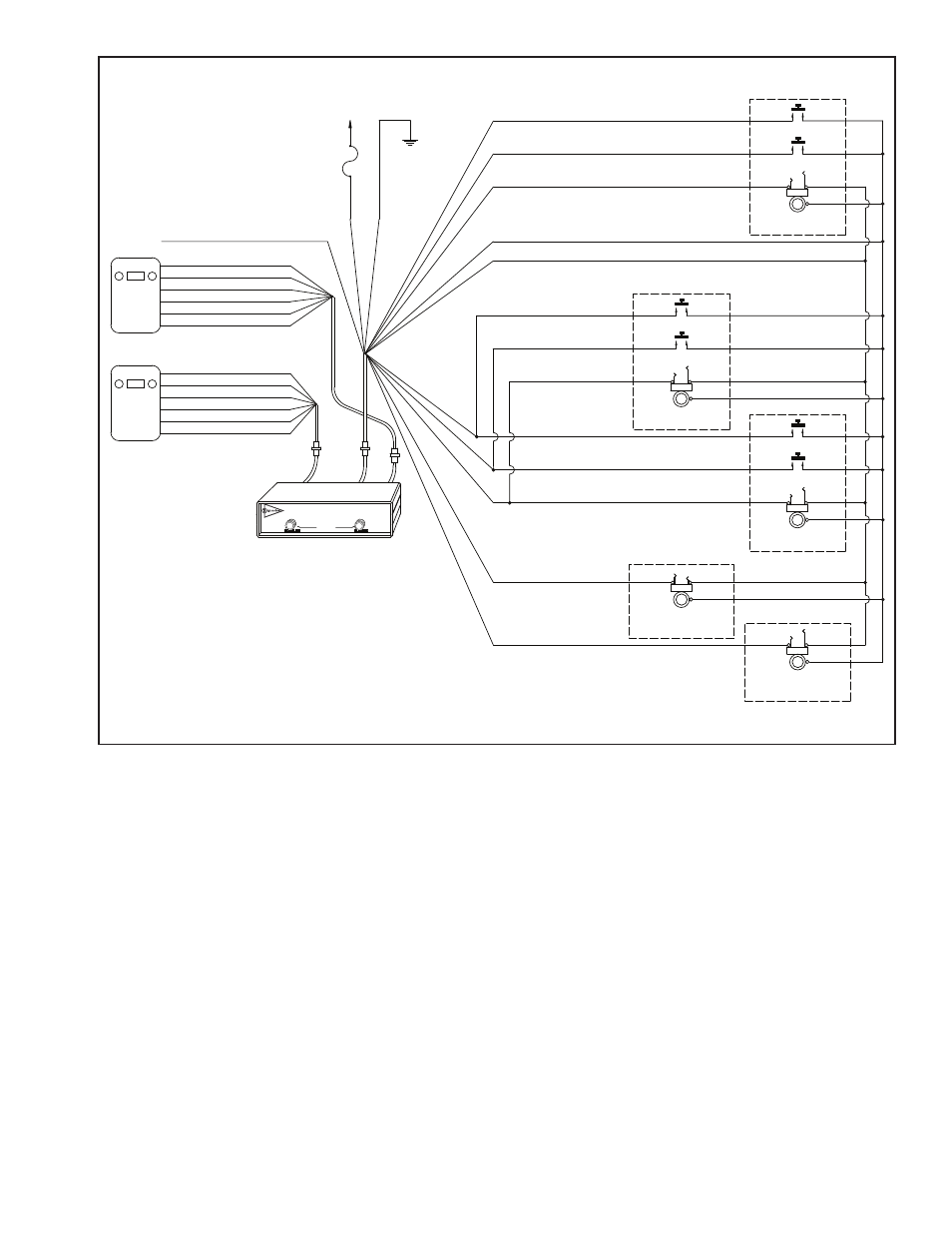

Ultrasound cfr wiring diagram figure 4 – Sigtronics Dual-CFR User Manual

Page 5

R

UltraSound CFR WIRING DIAGRAM

FIGURE 4

NOTES:

1) CONNECT EITHER VIOLET WIRE TO THE RADIO SPEAKER HI OUTPUT. CONNECT

THE REMAINING VIOLET WIRE TO SPEAKER LO.

2) CONNECT EITHER WHITE WIRE TO THE RADIO PUSH-TO-TALK (PTT) KEY LINE INPUT.

CONNECT THE REMAINING WHITE WIRE TO THE PTT KEY LINE RETURN (PTT LO).

(7) RED

+11 to +16

(1 AMP)

VOLTS DC

FUSE

CHASSIS

(12) GREEN

GROUND

MIC HI

PTT LO

MIC LO

PTT HI

SPEAKER HI

SPEAKER LO

(6) WHITE

(4) BLACK

(1) BROWN

(3) VIOLET

(5) WHITE

(2) VIOLET

NOTE 2

NOTE 2

NOTE 1

NOTE 1

SPEAKER LO

SPEAKER HI

PTT HI

MIC LO

PTT LO

MIC HI

(2) VIOLET

(1) BROWN

(4) BLACK

(5) WHITE

(3) VIOLET

(6) WHITE

NOTE 1

NOTE 1

NOTE 2

NOTE 2

RADIO 2

123

123

RADIO 1

P1

J1

J2

P2

J3

P3

INTERCOM UNIT

UltraSound

INTERCOM

UltraSound CFR

(15) WHITE / YELLOW NOT USED

(2) WHITE / RED

(1) WHITE / BLACK

(9) TAN

(3) BLUE

(8) TAN

(4) BLACK

HEADSET JACK

OFFICER

RADIO 1 PTT SWITCH

(5) ORANGE

RADIO 2 PTT SWITCH

TIP

BARREL

RING

HEADSET JACK

CREW #1

RING

TIP

BARREL

HEADSET JACK

CREW #2

TIP

RING

BARREL

(10) WHITE / BLUE

(11) WHITE / ORANGE

(6) WHITE / GREEN

(10) WHITE / BLUE

(11) WHITE / ORANGE

(6) WHITE / GREEN

HEADSET JACK

PUMP PANEL

PUMP PANEL OPTION

RADIO 1 PTT SWITCH

RADIO 2 PTT SWITCH

TIP

BARREL

RING

HEADSET JACK

DRIVER

RADIO 1 PTT SWITCH

RADIO 2 PTT SWITCH

TIP

BARREL

RING

Flexible four conductor hook-up wire is provided with each

system to connect each headset jack and PTT switch to the

UltraSound unit’s Headset Jack and PTT Switch Cable. Enough

wire is provided for a typical vehicle installation. If required,

additional hook-up wire can be purchased through your

Sigtronics dealer.

Each headset jack requires three wires. Each PTT switch

requires two. If an Officer’s PTT switch and headset jack are

mounted near each other, only four wires are needed.

Refer to the UltraSound Wiring Diagram (for CFR see Figure

4 above, for Dual-CFR see Figure 5 on page 6) for the exact

wiring information.

The connections between the Headset Jack and PTT Switch

Cable and the hook-up wire should be soldered and insulated

for reliability. Do not use crimp type splices. They can become

intermittent over time. Use a good quality electrical tape, or

better yet, use heat shrink tubing to cover the soldered

connections. The connections to the headset jacks and PTT

switches will also have to be soldered. See Figure 3 on page

4 for jack terminal identification.

We also do not recommend using screw type terminal strips

for intercom connections. There have been several instances

where terminal strips introduced high levels of electrical

noise like alternator whine into the intercom system. It is

acceptable however to tie the intercom red and green power

wires to existing vehicle terminal strips.

The best place to run the wiring between the unit and the

jack and PTT switches is out of sight. It should be run behind

vehicle panels and/or up in the headliner. This will reduce the

chance of personnel or equipment catching on or damag-

ing the wiring. Wire routing should take into account normal

vehicle operations. Wires should not interfere with any of the

vehicle’s controls, compartments, or doors. If the vehicle’s cab

tilts up for engine servicing, run wiring along the existing

vehicle wiring bundle. Make sure that wiring does not inter-

fere or restrict the tilting operation. Also, make sure that the

tilting operation will not cut or sever the wiring.

Make sure that the wiring does not rest on sharp edges. Over

time the vehicle’s vibration may cause a sharp edge to cut

into the wire. Use the provided wire grommets wherever

the four conductor wire goes through the hole into a jack

5