O.S. Engines FT-300 Gemini User Manual

Page 9

Installation procedure is as follows:

1) Ream the propeller centre hole to the size indicated in

the separate instructions sheet. Make sure that the

propeller is properly balanced.

2) Fit the propeller sleeve-nut and washer to propeller,

screw onto shaft and tighten firmly with 17 mm wrench

supplied.

If the Safety Propeller Lockout Assembly of your engine

is supplied with the Locknut Spacer, add the Spacer if

the dimension "T" indicates you should do so, in the

separate instructions sheet.

3) Finally, insert the Safety Propeller Locknut. Tighten

Locknut firmly (but not with excessive force) using

14 mm wrench.

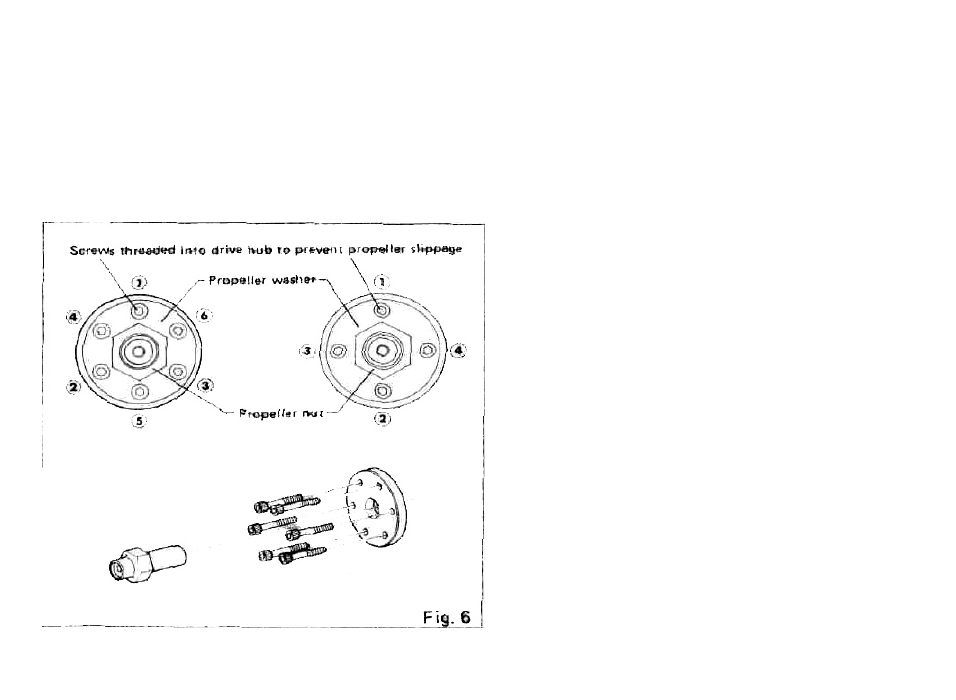

PROPELLER WASHER SET FOR SCALE MODEL

If you prefer to use the standard prop-nut and retaining

screws (see Fig. 6) to obtain more scale-like appearance

choose a propeller that has a boss at least as large as the

diameter of the drive hub so that it is not weakened when

drilied for the retaining screws. If the screws are not used,

the propeller may loosen (due to detonation when running

or preignition when starting) and, if the engine is running,

the propeller will fly off, complete with the retaining nut

and washer. This can be very dangerous.

Therefore, secure the prop nut and screws as follows:

1) Drill 3 mm diameter holes accurately through propeller

boss to exactly align with those in prop washer and drive

hub. Do not drill holes oversize.

2) Install prop, prop washer, screws and prop nut.

3) Tighten prop nut.

4) Tighten screws progressively and evenly in the order

shown in the sketch.

5) Repeat steps 3) and 4) above to make sure that the prop

is really secure.

-8-