O.s.engines mfg.co.,ltd, Parts list – O.S. Engines FT-300 Gemini User Manual

Page 18

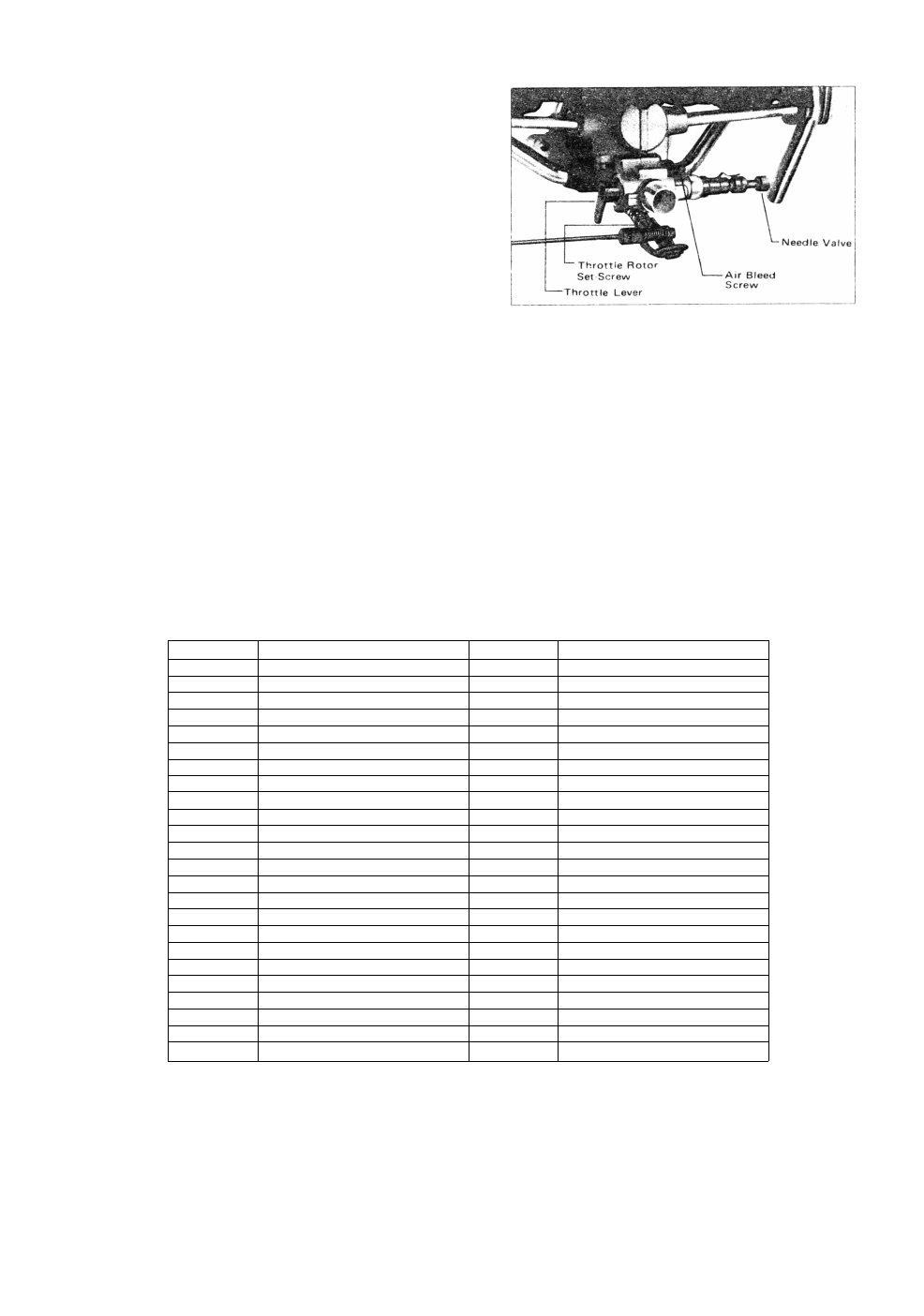

1) Start the engine, with the throttle 1/3 open from the

fully closed position, then open the throttle fully and

gradually close the needle-valve until the engine is run-

ning at its maximum speed.

CAUTION: Do not close the needle-valve to too "lean" a setting as

this will cause the engine to overheat and slow down.

Set the needle-valve very slightly to the "rich" side of

the peak r.p.m. setting. Make sure that the engine is

fully "broken-in" (about 1 hour of total running time

in short runs) before operating it continuously at full

throttle.

2) Now, close the throttle gradually. The engine should idle

continuously and steadily. If it does not. adjust as

follows.

a) If the engine begins to idle unevenly, first re-open the

throttle. If the engine hesitates before picking up to

full speed, it is probable that the idling mixture is too

rich. Check this by closing the throttle again and let-

ting the engine idle for a little longer before again

opening up. If the engine now puffs out a good deal

of smoke and hesitates or even stops, it will be neces-

sary to screw out the air-bleed screw to weaken the

mixture. Do this by turning it counter-clockwise.

About 1/2-1 turn should be sufficient.

b) If, instead of being too rich, the air-bleed screw is set

too lean, the engine will stop when the throttle is

closed, or will lose speed while idling and then cut-

out abruptly (without smoking) when the throttle is

opened again. In this case, turn the air-bleed screw

about 1/2-1 turn clockwise.

3) When the mixture, has been corrected, the idling speed

will probably increase. Re-adjust the throttle opening by

means of the throttle trim on the transmitter or by

screwing-out the throttle-stop screw so that the lowest

possible idling speed, without stopping the engine, may

be obtained.

4) It is recommended to. repeat procedure 2) several times

until the best result is obtained.

Subsequent Operation and Care

Once the required carburettor settings have been establish-

ed, it should be unnecessary to alter them. Such slight

needle-valve alterations as may be needed to cope with dif-

ferences in atmospheric conditions or fuels, do not affect

the other two adjustments.

It is important that the carburettor operates under clean

conditions. Make sure that the fuel is properly filtered

before use. We advise fitting a filter in your fuel can and

another in the delivery tube between tank and engine, to

reduce the risk of the carburettor jet becoming partially

clogged and upsetting running adjustments.

Remember to clean the filters occasionally.

PARTS LIST

Code No.

46101000

46101800

46102000

46103100

45903200

46103300

45403400

46104020

46104110

46104200

46105000

45906000

46108000

45508200

46120000

46110100

46013002

46114000

26731002

22130004

46030008

46031005

22631019

46160000

Description

Crankcase

Rear Housing

Crankshaft

Cylinder Liner

Piston

Cylinder Jacket

Piston Ring

Cylinder Head (w/valve assy)

Cylinder Head

Rocker Cover

Connecting Rod Assembly

Piston Pin

Drive Washer

Woodruff Key

Thrust Washer

Propeller Locknut Set

Screw Set

Head Gasket Set

Crankshaft Bearing (front)

Crankshaft Bearing (intermediate)

Crankshaft Bearing (rear)

Camshaft Bearing (front)

Camshaft Bearing (rear)

Valve Assembly (1 pc.)

Code No.

45361000

45961400

46162000

45564000

46166000

45566100

46168000

46168500

46168100

46168200

46169000

45471000

46109400

46181000

46184000

71615009

72200060

72200040

46130000

72200080

71910000

*46110200

*72403050

Description

Rocker Arm Assembly (1 pc.)

Rocker Support Assembly

Camshaft

Cam Follower (2 pcs.)

Push Rod (2 pcs.)

Push Rod Cover Set (2 pcs.)

Intake Manifold

Manifold Seal (2 pcs.)

Intake Pipe (right)

Intake Pipe (left)

Exhaust Pipe (1 pc.)

Breather Nipple (w/gasket)

Propeller Spacer

Carburettor Complete

Choke Valve Assembly

Glow Plug Type F

Valve Adjusting Tool Kit

Booster Cable Set

Scale Propeller Washer Set

Needle-valve Extension Cable

Radial Motor Mount Set

5/16-M5(L) Propeller Lockout Set

Super Filter (large)

* Optional Parts The specifications are subject to alteration for improvement without notice.

O.S.ENGINES MFG.CO.,LTD

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. (06) 702-0225

FAX. (06) 704-2722

Copyright 1990 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan