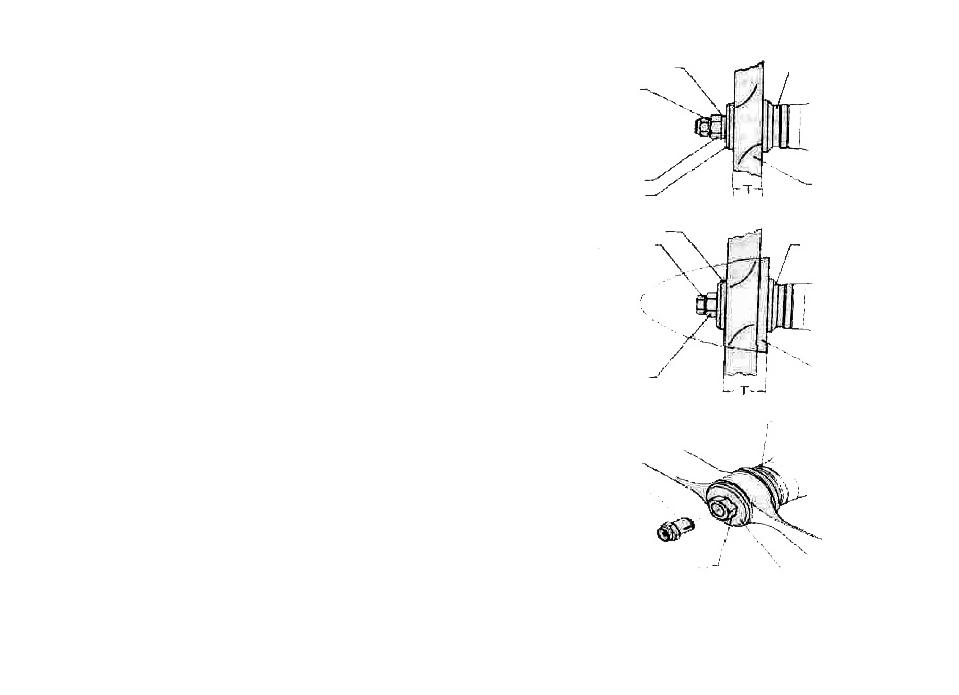

Fig. 3, Fig. 4 – O.S. Engines FT-300 Gemini User Manual

Page 8

PROPELLER

The choice of propeller depends on the size and weight of

the model and on the type of flying envisaged. Determine

the best size after practical experiment.

Suggested propellers are shown in the separate instructions

sheet. For safety, keep your face and other parts of the

body well away from the propeller when starting the engine

or when adjusting the needle-valve while the engine is run-

ning. Remember that the propeller turns through a much

wider arc with the larger sized propellers that this engine is

capable of driving.

Refer to the "Safety Instructions and Warnings" leaflet

enclosed.

IMPORTANT: Use well balanced propellers only. An

unbalanced propeller causes vibration and

loss of power.

The larger displacement O.S. engines were originally

designed so that the propeller could be fixed to the engine

with screws, as weil as the usual nut, in order to prevent

propeller slippage. However, if the propeller nut or screws

are inadequately tightened, this can (due to detonation or

"knocking" if the engine is run too lean or under too heavy

a load) cause the propeller to split and fly off. Obviously,

this can be very dangerous.

It is recommended, therefore, to use the Safety Propeller

Locknut Assembly supplied with the engine to prevent the

propeller from fracturing or flying off, even if it loosens.

(See Figs 3, 4 & 5)

Lockout spacer

Lockout

Propeller nut

Propeller washer

Propeller washer

Lock nut

Propeller nut

Drive hub

Propeller

Drive hub

Fig. 3

Back-plate of spinner

Fig. 4

Drive hub

Propeller washer pig. 5

Locknut

Propeller nut

-7-