LAARS Mighty-Stack TL80-199 - Installation, Operation and Maintenance Instructions User Manual

Page 7

Mighty Stack Water Heater

Page 7

1J. General Venting Instructions

WARNING

This water heater must be vented in accordance

with Part 7, Venting of Equipment, of the latest

edition of the National Fuel Gas code, ANSI Z223.1

and all applicable local building codes. In Canada,

follow CAN/CGA B149 Installation codes. Improper

venting of this appliance can result in excessive

levels of carbon monoxide which can result in

severe personal injury or death!

Here are some general rules to follow when

venting this unit:

• Place the water heater as close as possible to the

vent or chimney.

• The vent collar on the water heater must be

fastened directly to an unobstructed vent pipe.

Use rustproof sheet metal screws no longer than

1/2" (13 mm).

• Do not weld the vent pipe to the water heater

collar. The weight of the stack must not rest on

the water heater. The top of the water heater

must be easily removable for normal service and

inspection of the unit.

• The water heater vent must not be connected to a

fireplace, wood stove or other equipment which

burns solid fuel.

• Avoid terminating the water heater vent near any

air-conditioning or air-supply fans. These fans

can pick up the exhaust flue products from the

water heater and return them to the building.

This can create a health hazard.

• Avoid using an oversized vent pipe or using

extremely long runs of the pipe. This may cause

excessive cooling and condensation of flue

gases.

1K. Vertical Venting – Category I

This unit can be vented into a masonry chimney,

provided several conditions are met (see Figure 6).

• The chimney must have an appropriate tile lining.

The lining should be the correct size, should be

constructed correctly, and must be clean.

• Check the chimney passage way to be sure that it

is clear and free of obstructions.

• If the chimney must be rebuilt, follow nationally-

recognized standards. (See the National Building

Code or ANSI/NFPA 211.)

For installation in U.S.A.:

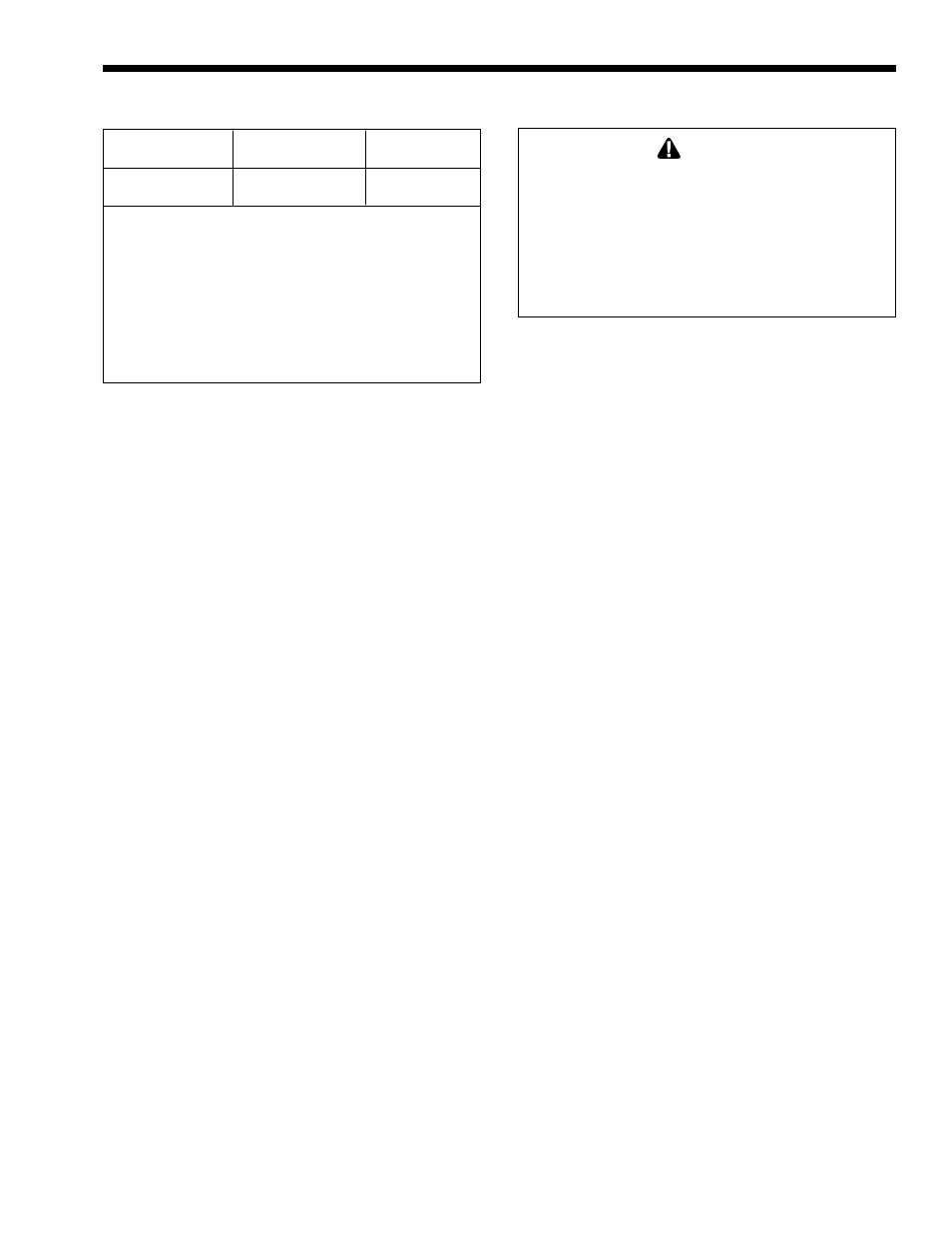

Water Heater

Outside Air

Inside Air

Size

Area

†

Area

††

199

50 sq in.

199 sq in.

323 sq cm

1284 sq cm

The area indicated is for one of two openings; one at floor

level and one at ceiling, so the total net free area would be

double the figures indicated. For special conditions, refer to

NFPA54 ANSI Z223.1.

†

Outside air supply – Combustion air is supplied directly

through an outside wall.

††

Inside air supply – Combustion air is supplied from inside

the building.

NOTE: Check with louver manufacturers for Net Free Area

of Louvers. Correct for screen resistance to the New Free

Area if a screen is used.

Table 5. Minimum Recommended Air Supply

to Water Heater Room.

Outside Air Supply: When combustion air is

supplied directly through an outside wall, each

opening should have a minimum free area of one

square inch per 4,000 BTUH input of the total input

rating of all appliances in the enclosed area.

Inside Air Supply: When combustion air is

supplied from inside the building, each opening

should have a minimum free area of one square inch

(6.5 sq cm) per 1,000 BTUH input of the total input

rating of all appliances in the enclosed area. These

openings should never be less than 100 square inches

(645 sq cm).

For installation in Canada:

NOTE: In Canada, follow Canadian Standard

CAN/CGA-B149 or local codes.

Exhaust Fans or Vents: Any equipment which

exhausts air from the room around the unit can deplete

the combustion air supply. Such equipment can also

reverse the action of the venting system. This could

cause flue products to accumulate in the space where

the water heater is installed. Additional air must be

supplied to compensate for any exhaust effect.

The information in Table 5 is not applicable in

installations where exhaust fans or blowers of any

type are used. Such installations must be designed by

qualified engineers.

If a blower or fan is used to supply air to the

water heater room, the installer should make sure it

does not create drafts which could cause nuisance

shutdowns. If a blower is necessary to provide

adequate combustion air to the water heater, a switch

or equivalent must be wired into the water heater

control circuit to prevent the water heater from firing

unless the blower is operating.

The water heater must be protected from any

source of corrosive chemical fumes including those

emitted by trichlorethylene, perchlorethylene,

chlorine, etc.