Out of production – LAARS Mighty Max VW (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 6

Page 6

LAARS Heating Systems

NOTE: The heater and all other gas appliances

sharing the heater gas supply line must be firing at

maximum capacity to properly measure the inlet

supply pressure. Low gas pressure could be an

indication of an undersize gas meter and/or

obstructed gas supply line.

8.

Do not exceed the maximum inlet gas pressures

specified. Excessive pressure will result in

damage to the heater's gas controls. The

minimum pressures specified are for gas input

adjustment.

9.

The correct differential gas pressure is stamped

on the rating plate. The regulator is preset at the

factory, but may need adjustment for altitude per

Section 3.

10. Before operating the heater, test the complete gas

supply system and all connections for leaks using

a soap solution.

CAUTION

Since some leak test solutions (including soap and

water) may cause corrosion or stress cracking,

rinse the piping with water after testing.

ATTENTION

La commande d’allumage fonctionne sur un

courant de 120V. Pensez-y lorsque vous travaillez

sur le chauffe-eau et prenez soin d’éviter tout

contact avec des pièces branchées sur le courant

qui causeraient une électrocution, conduisant à des

dégâts matériels, aux blessures voire à la mort.

2.7 Water System Piping

2.7.1 Water Chemistry

Laars equipment is designed to be used in a

variety of water conditions. The water velocity in the

heat exchanger tubes is kept high enough to prevent

scaling from hard water, yet low enough to avoid

erosion by soft water. The water in 95 percent of the

urban centers in the United States is compatible with

this equipment, but in some areas a water supply will

contain a large quantity of scaling chemicals or the

water may be extremely soft or erosive. In rare

situations the water will contain both scaling

chemicals and erosive chemicals such as calcium or

sodium chloride. These conditions may be caused by

well water or a nearby pumping station, and the

particular condition may not be characteristic of the

entire city water system.

NOTE: It is possible to have hard and soft water in

the same city. Check with the local water company.

If an installer sees damage to any water handling

equipment at the installation site, it should be repaired

as soon as possible to help reduce maintenance costs.

If there is erosion, resize the pump to reduce water

velocity before the tube ruptures. If scaling is bad, set

up a heat exchanger tube-cleaning maintenance

schedule to prevent heat exchanger tube cracking and

wear. Not fixing the condition may cause serious

damage to the heater and the water system.

Scaling is a layer on the inner surface of the heat

exchanger tubes which restricts the flow of water.

Scale can be any color or texture, smooth or rough,

granular or amorphous. Erosion is usually identified

by pitting, cavitation, ridges and “islands” on the inner

surfaces of the heat exchanger tubes. If this is caused

by extremely soft water, or a water softener in the

system, the internal copper surfaces will be very

shiny. Other chemicals, such as chlorine or chlorides

in the water, will cause dark patches of erosion.

NOTE: Laars does not warrant heat exchangers

damaged by scaling, corrosion, or erosion.

2.7.2 Water Piping

Minimum inlet water temperature is 120°F

(49°C).

VW heaters are intended for heating large

volumes of water at constant flow rates, usually for

storage in a tank. Heaters in this type of application

are sometimes called circulating water heaters.

Figure 5 shows the VW heater with tank and two

pumps. One pump (recirculation) only circulates the

hot water through the building plumbing. The other

pump (heater) circulates water between the tank and

the heater. This heater circulating pump is essential for

proper operation of the heater (see Section 2.7.5).

The heater circulating pump must be sized to

provide enough flow to prevent damage to the heat

exchanger, and must handle the hardness or softness

of the water being heated. Generally, hard water must

be pumped at higher velocity; however, soft water will

erode holes in the heat exchanger tubing if pumped

too fast.

The Mighty Max VW heater comes standard

with copper tubes, but in areas where the water supply

is soft or corrosive, the heat exchanger should be

factory ordered with cupronickel tubes. Consult the

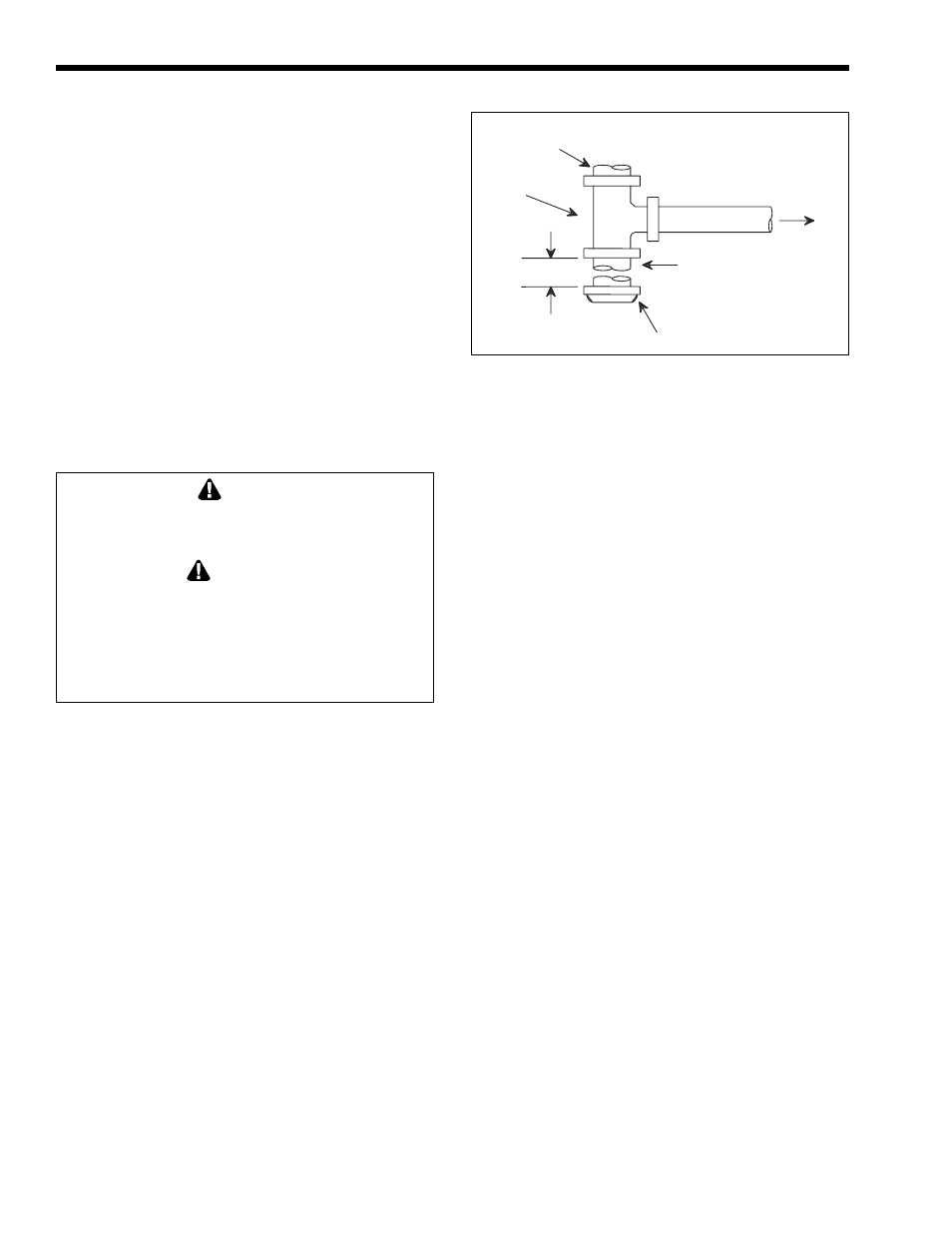

Figure 4. T-Fitting Sediment Trap Installation.

Gas Supply

Inlet

3 in.

(76mm) Min.

Cap

Nipple

To Equipment

Inlet

Tee

Fitting

OUT OF

PRODUCTION