Out of production – LAARS Mighty Max VW (Sizes 320M - 400M) - Installation, Operation and Maintenance Instructions User Manual

Page 20

Page 20

LAARS Heating Systems

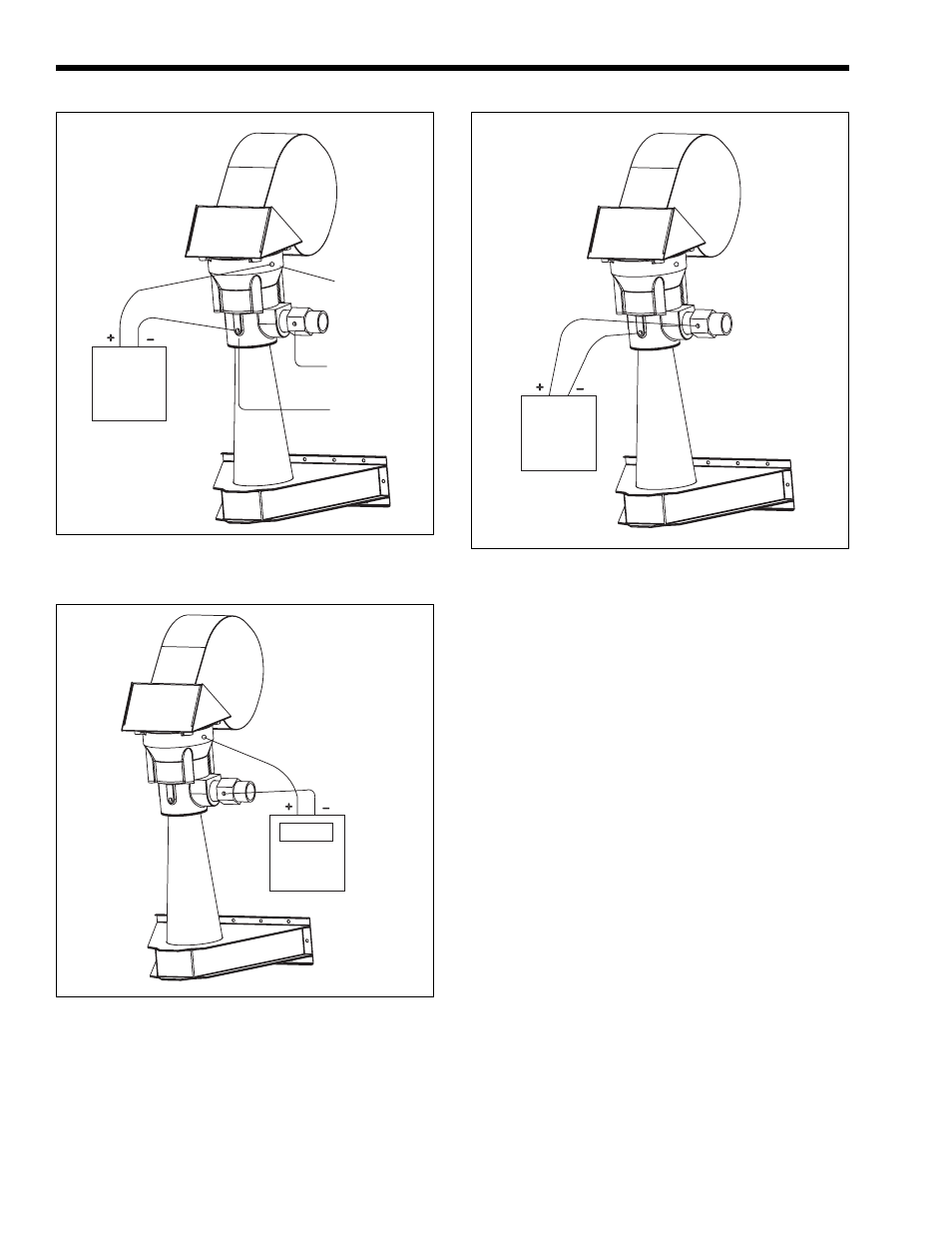

Figure 14. Unfired Venturi Differential Pressure -

Natural Gas.

5.8" WC

Gas

Plenum Tap

Gas

Orifice Tap

Venturi

Inlet Tap

Figure 15. Gas Offset Pressure - Natural Gas.

0.4" WC

Figure 16. Gas Orifice Differential Pressure - Natural Gas.

4.0" WC

a. Unfired Venturi Differential Pressure

NOTE: Turn off the main manual gas valve.

The difference in pressure between the venturi

inlet tap and the gas plenum tap (see Figure 14). This

measurement is taken by connecting the positive side

of the manometer to the venturi inlet tap and

connecting the negative side of the manometer to the

gas plenum tap. This measurement is taken with the

boiler not firing. It is a temporary setting used to start

the boiler and check for air flow problems.

b. Gas Offset Pressure - Natural Gas

The difference in pressure between the venturi

inlet tap and the outlet of the gas regulator (see

Figure 15). This measurement is taken by connecting

the positive side of the manometer to the venturi inlet

tap and connecting the negative side of the manometer

to the gas orifice tap. This measurement is an

indication of the gas to air ratio and must be

performed while the unit is firing.

c. Gas Orifice Differential Pressure -

Natural Gas

This measurement is the pressure drop across the

gas orifice. This measurement is taken by connecting

the positive side of the manometer to the gas orifice

tap and the negative side of the manometer to the gas

plenum tap (see Figure 16). This measurement in

conjunction with the gas orifice size is an indication of

the gas firing rate and must be performed while the

unit is firing.

OUT OF

PRODUCTION