LAARS Pennant PNCP - Install and Operating Manual User Manual

Page 14

LAARS Heating Systems

Page 14

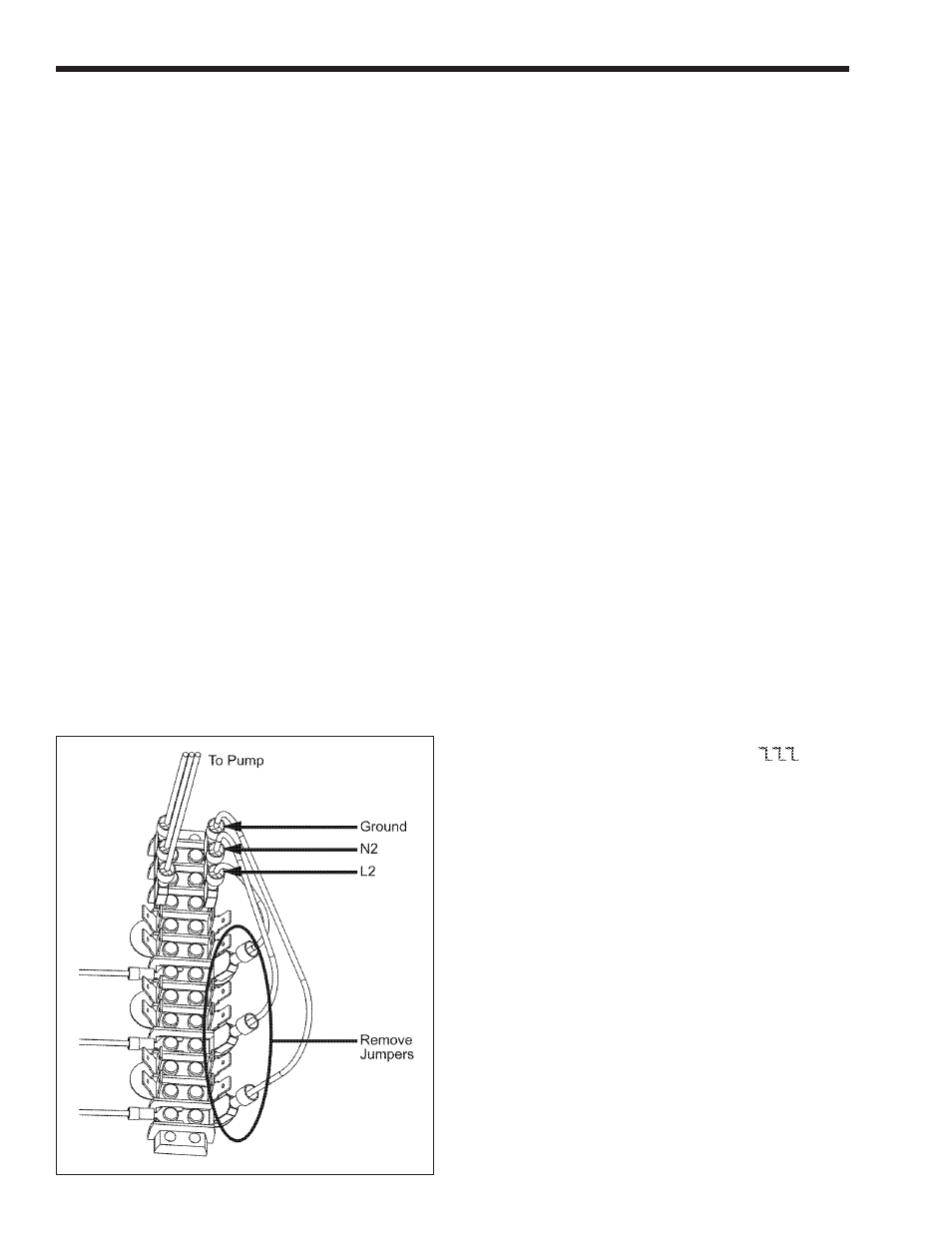

spade (fork) terminal. From the other side of the main

power switch connect to the main terminal block using

a ¼" female insulated quick connect. This will be

the same position where the jumper had terminated

(see Figure 7). Connect N2 and Ground to the main

terminal block using ¼" female insulated quick

connect (refer to Figure 7).

5.1.4 Auxiliary Time Clock Wiring

If a time clock is used to control the pool filter

pump operation, a separate switch or relay must be

used to shut off the heater at least 15 minutes before

the filter pump is shut off. A remote switch or relay,

if installed, should be connected across the “Other

Ints” terminals on the field-wiring terminal strip (see

Figure 9) after removing the factory-installed jumper

from those terminals. For manual shut off, a switch is

provided and identified with a label on the right side of

the heater.

All field-installed electrical safety devices and

controllers may also be connected across the Pennant’s

“Other Ints” terminals after the factory-installed

jumper is removed. If a remote switch or relay

(mentioned above) is installed, the other field-installed

electrical safety devices and controllers should be

wired in series with that switch or relay.

5.1.5 All Sizes

Wiring diagrams are shown in Section 10 in

Figures 13 through 17. Field wiring is shown in

Section 10 in Figure 18.

IMPORTANT NOTE: If the backwash operation is

manual the heater must be shut off manually during

backwashing.

5.2 Temperature (Operating) Control

The Pennant temperature control operates by

measuring the pool loop return temperature, before

the heater inlet piping. It is adjustable to a maximum

of 104° F and will prevent heater operation at return

temperatures above 104° F. It also controls the pool

heater pump and the temperature of the water entering

the heat exchanger. It also controls the Pennant pump

operation and the mixing system, which tempers the

water entering the heat exchanger to prevent damage

from condensation. The sensors for the control

are installed as shown in Figure 6 and Section 4.3,

Sensor Locations. The automatic mixing system

sensor, already installed, is shown in Figure 5. During

operation, the automatic mixing system diverts water

from the outlet to the inlet to “pre warm” the water to

a minimum inlet temperature of 120°F. This prevents

condensation from forming, which can damage the

heater.

5.3 Programming the Temperature

Control

5.3.1 Temperature Control Overview

The digital display on the control has the

following uses:

•

To display the actual pool loop temperature

during normal operating mode.

•

To allow the user to view and adjust the

control settings.

Figure 8 identifies the control buttons.

The Pool Heater Temperature Control face

contains an LCD screen and four (4) buttons (see

Figure 8). The LCD screen will display the pool loop

return temperature during normal operation. When

the control is first powered up, it displays

. It

then displays the temperature at the pool loop sensor.

After the temperature is displayed, the current settings

(parameters) may be viewed. To scroll through the

parameters, press the down arrow button to advance to

the next parameter.

5.3.2 Programming Control Parameters

There are four (4) control parameters that may

be set. They are the Pool Loop Temperature (LSP), the

Pool Loop Temperature Differential (dLS), the Boiler

Temperature (bsp) and the Pump Off Delay (Pd).

The pool loop temperature (desired pool

temp-erature) is set by changing the LSP parameter.

After scrolling through the parameters until LSP is

displayed, press the enter button. The setpoint will be

displayed. Press the up arrow or down arrow buttons

until the desired setpoint is displayed. Press the

enter button and the setpoint will be activated. The

display will return to indicating the present pool loop

temperature.

In addition to the ability to set the pool loop

temperature, the differential associated with that

setting may also be adjusted. The differential is set by

Figure 7. Removing Jumpers.