LAARS Pennant PNCP - Install and Operating Manual User Manual

Page 11

Pennant Pool Heater

Page 11

DISTANCE FROM GAS METER

SIZE AND

OR LAST STAGE REGULATOR

GAS TYPE

0-100' 0-31m 100-200' 31-61m 200-300' 61-91m

500 natural

1-1/2" 3.8cm 2"

5.1cm 2"

5.1cm

500 propane 1" 2.5cm 1-1/2" 3.8cm 1-1/2" 3.8cm

750 natural 2" 5.1cm 2"

5.1cm 2-1/2" 6.4cm

750 propane 1-1/2" 3.8cm 1-1/2" 3.8cm 2"

5.1cm

1000 natural 2" 5.1cm 2-1/2" 6.4cm 3"

7.6cm

1000 propane 1-1/2" 3.8cm 2"

5.1cm 2-1/2" 6.4cm

1250 natural 2-1/2" 6.4cm 2-1/2" 6.4cm 3"

7.6cm

1250 propane 2"

5.1cm 2"

5.1cm 2-1/2" 6.4cm

1500 natural 2-1/2" 6.4cm 3"

7.6cm 3"

7.6cm

1500 propane 2"

5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm

1750 natural 2-1/2" 6.4cm 3"

7.6cm 3"

7.6cm

1750 propane 2"

5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm

2000 natural 3" 7.6cm 3"

7.6cm 3-1/2" 8.9cm

2000 propane 2-1/2" 6.4cm 2-1/2" 6.4cm 3"

7.6cm

Notes:

1. These figures are based on 1/2" (0.12kPa) water column

pressure drop.

2. Check supply pressure and local code requirements before

proceeding with work.

3. Pipe fittings must be considered when determining gas pipe

sizing.

Table 7. Gas Piping Size.

SECTION 3.

Gas Supply and Piping

3.1 Gas Supply and Piping

Gas piping should be supported by suitable

hangers or floor stands, not by the appliance.

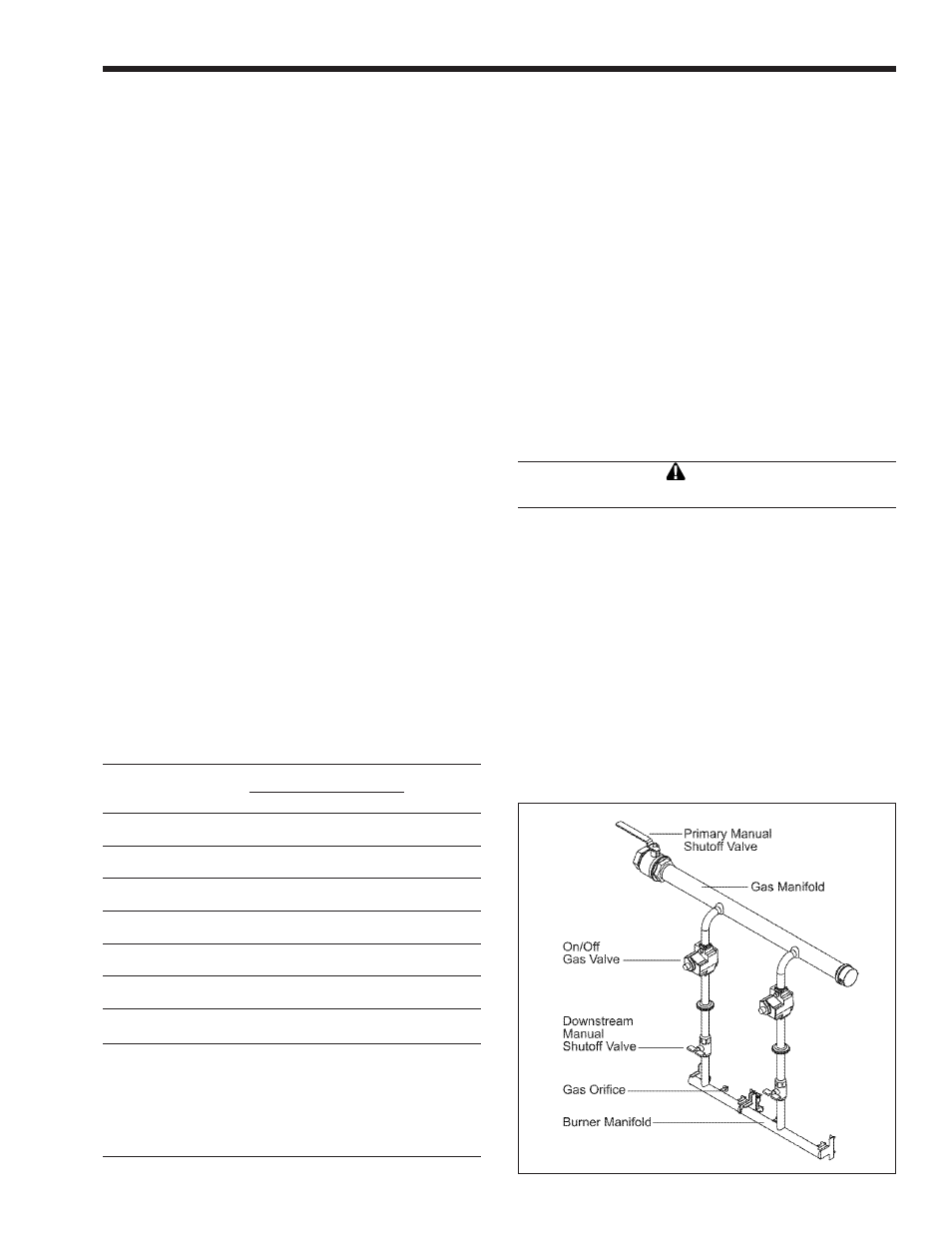

The Pennant’s gas train allows the user to pipe

the gas from either the right side or the left side of

the unit. As shipped, the right side of the gas train is

capped off, and there is a manual valve on the left side.

If desired, the manual valve on the left side of the gas

train may be moved to the right side, and the cap on

the right side may be moved to the left.

Review the following instructions before

proceeding with the installation.

1. Verify that the appliance is fitted for the proper

type of gas by checking the rating plate. Laars

Heating Systems appliances are normally

equipped to operate at elevations up to 2000 feet

(610m). Pennant appliances may be adjusted to

operate properly at higher elevations; however,

input will be reduced if the heating value of the

gas supply is below sea level values.

2. The maximum inlet gas pressure must not exceed

13" W.C (3.2kPa). The minimum inlet gas

pressure is 5" W.C. (1.2kPa).

3. Refer to Table 7, size supply.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of

the gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of liquefied

petroleum gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45kpa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 PSIG (3.45kpa).

10. The appliance and its gas connection must be

leak tested before placing it in operation.

11. Purge all air from gas lines.

Caution

Do not use open flame to check for leaks.

NOTE: The Pennant appliance and all other gas

appliances sharing the gas supply line must be firing

at maximum capacity to properly measure the inlet

supply pressure. The pressure can be measured at

the supply pressure port on the gas valve. Low gas

pressure could be an indication of an undersized

gas meter, undersized gas supply lines and/or an

obstructed gas supply line. The Pennant may not fire if

the gas pressure lower than 5" w.c.

Figure 4. Typical Gas Train Configuration.