LAARS Mighty Therm VW (Sizes 2000-5000) - Installation, Operation and Maintenance Instructions User Manual

Page 4

LAARS Heating Systems

Page 4

1.3 Water Chemistry

Laars equipment is designed for use in a wide

variety of water conditions. The water velocity

maintained in the heat exchanger tubes is kept high

enough to prevent scaling from hard water, and at the

same time, low enough to avoid corrosion from soft

water. Most of the urban areas in the country have

water that is compatible with this equipment. In some

areas a water supply will contain a heavy quantity of

scaling chemicals, or the water may be extremely soft

and corrosive. In rare situations, the water will contain

both scaling chemicals and corrosive chemicals such

as calcium, or sodium chloride. These conditions may

be the result of a nearby well or pumping station, and

the particular condition may not be characteristic of

the entire city water system.

If an installer observes damage from these

conditions to any water handling equipment in the

area, a factory representative should be contacted

immediately for assistance in minimizing maintenance

costs. If erosion is present, the pump impeller can be

replaced to reduce water velocity. If scaling

conditions are bad, tube cleaning maintenance

schedules can be established to prevent tube burn-out

and cracking. Neglecting the problem could mean

serious damage to the heater and water system.

Scaling can be recognized as a layer deposited

on the inner walls of the tubes which reduces the inner

diameter of the tube. Scale can be any color or

texture; smooth or rough, granular or amorphous.

Erosion is generally evidenced by pitting, cavitation,

ridges and “islands” on the inner walls of the tubes.

Where this condition results from extremely soft

water sources, or as a result of a water softening

program, the internal copper surfaces will be

extremely shiny. Other chemicals, such as chlorine or

chlorides in the water, will result in dark surfaces of

erosion.

In areas where the water supply is extremely

corrosive, it is advisable to order the heater with

cupronickel tubes in the exchanger.

Damage from scaling, corrosion, or erosion is

not covered by the warranty.

SECTION 2.

Installation

2.1 Heater Placement

The heater must be placed to provide clearances

on all sides for maintenance and inspection. There

must also be minimum distances maintained from

combustible surfaces.

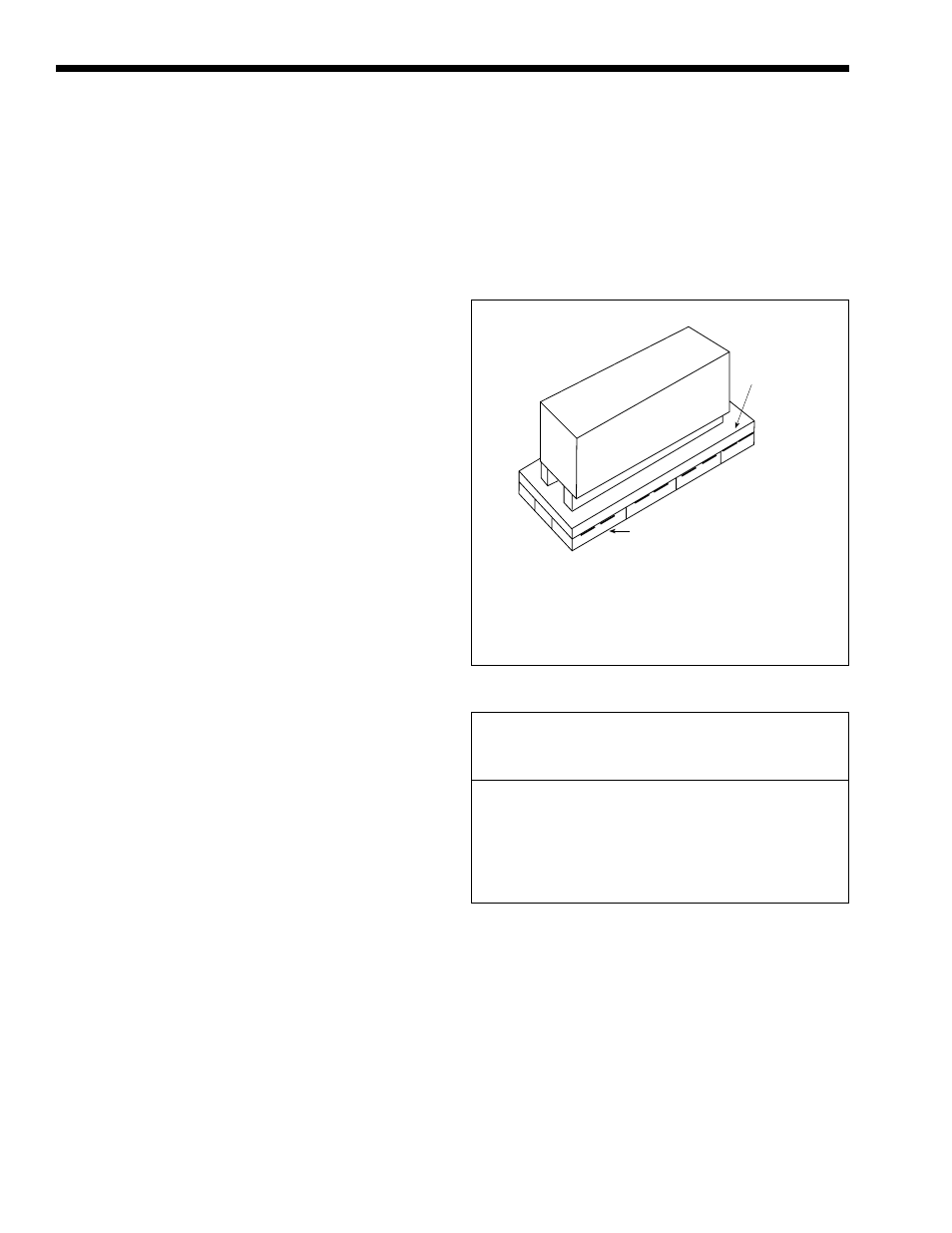

All heaters must be installed on a non-

combustible flooring. Under no circumstances can

heaters be installed on carpeting.

Base Must Extend Out

Min. 12" On All Sides

Of Heater Frame

Metal Plate

20 Ga. Min.

Under Entire

Heater

Concrete Blocks Or Tile

Min. 7" High With 3" Min.

Air Openings

Blocks must provide solid base and be braced

so they cannot slip out of place. Air openings

in blocks must be arranged to provide

unobstructed opening through entire width or

length of base.

Clearance

Indoor

Outdoor

From

(Inches)

(Inches)

Top

24

—

Water Conn. Side

24

24

Opposite Side

24

24

Front

48

48

Rear

24

24

Vent

6

—

Table 1 – Minimum Heater Clearances From

Combustible Surfaces.

The National Fuel Code allows a heater to be

placed on other than a non-combustible surface when

such an installation complies with the local codes.

This code specifies the surface under the heater be

protected with hollow masonry no less than 4" thick,

covered with sheet metal at least 20 gauge in

thickness. Such masonry must be laid with ends

unsealed, and joints matched in such a way as to

provide a free circulation of air from side to side

through the masonry (see Figure 2).

Figure 2. Non-Combustible Base.

2.2 Indoor Installation

2.2.1 Combustion Air Supply

1.

The heater location must provide sufficient air

supply for proper combustion, and ventilation of

the surrounding area as outlined in the latest

edition of ANSI standard Z223.1 and in Canada,

CAN1-B149 requirement, and any local codes

that may be applicable. Inadequate combustion

air supply may result in incomplete combustion

and consequent sooting of the heat exchanger

and unsafe operation of the heater.