LAARS Mighty Therm VW-PW (Sizes 175-400) - Installation, Operation and Maintenance Instructions User Manual

Page 24

LAARS Heating Systems

Page 24

4.3 HEAT EXCHANGER

4.3.1 Inspecting the Heat Exchanger

To check the scale buildup, periodically inspect

the tube having the highest temperature as follows:

1.

Open the drain valve on the left side of the

heater.

2.

Remove the hex-head plug located on the right

side of the heater under the in/out header (see

Figure 32). Perform this inspection after 60 days

of and after 120 days of operation. This will

establish a regular inspection routine.

4.3.2 Cleaning the Heat Exchanger

An inspection and cleaning of the complete heat

exchanger can only be done by removing it from the

heater.

1.

To remove the heat exchanger, refer to Section

2.6.1.

Caution

Black carbon soot buildup on a dirty heat exchanger

can be ignited by a random spark or flame. To

prevent this happening, dampen the soot deposits

with a wet brush or fine water spray before servicing

the heat exchanger.

2.

Remove the heat baffles and check for a light

accumulation of soot or corrosion on the outside

of the heat exchanger tubes.

NOTE: While the heat exchanger is out of the

heater, inspect the firewall refractory insulation blocks

for cracks, wear, and breakage. Replace if necessary.

3.

Use a wire brush to remove soot and loose scale

from the heat exchanger. Do not use water or

compressed air for cleaning.

NOTE: Use only the correct carbide tipped

reamers which are available from Laars.

4.

Ream the insides of the tubes (see Figure 33).

5.

Pull the reamer out frequently to remove lime

powder and prevent the drill from binding in the

tube.

6.

Install new gaskets. Do not reuse the old ones.

7.

Tighten the header bolts progressively, starting

with the two center bolts. Maximum torque is 20

inch pounds (27 Nm). Do not over-torque.

8.

Pressure test the heat exchanger for leaks with

city water supply before re-installing (see

Figure 33).

9.

When placing the heat exchanger back in the

heater, carefully hold the refractory insulation

blocks apart and lower the heat exchanger into

place. Be sure the sheet metal covers, which

protect the insulation blocks, are replaced

carefully.

10.

If a header bolt is stripped, drive it out of the

header plate and replace it (see Section 6, Parts

List).

11.

To reinstall the heat exchanger, refer to Section

2.6.1.

SECTION 5.

Troubleshooting and Service

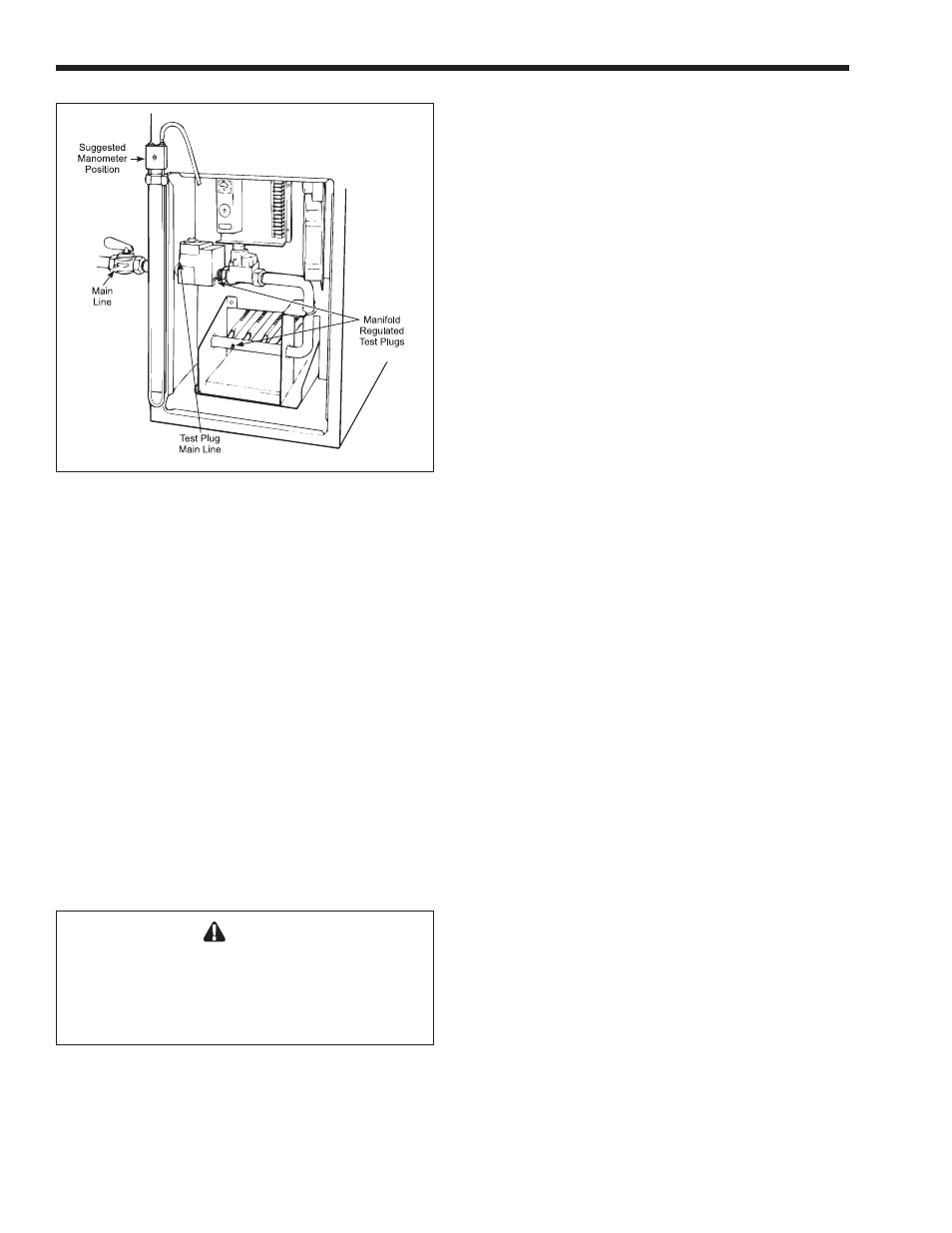

5.1 Gas Pressure Tests

Use the following procedures to check the main

gas and manifold regulated gas pressures. A

manometer kit is available from Laars and instructions

for its use are included in the kit. A dry gas pressure

gauge may also be used for either test.

5.1.1 Checking the Main Line

Gas Pressure

1.

Attach a manometer (or a dry gas pressure

gauge) to heater jacket (see Figure 34).

2.

Open both columns on the manometer.

3.

Use shutoff valve outside the heater jacket to

shut off all gas supply to the heater.

4.

Remove the 1/8 inch Allen Plug on the inlet side

of the gas valve and replace it with the 1/8 inch

(3.2 mm) NPT fitting from the manometer kit.

Figure 34. Gas pressure test.