LAARS Mighty Therm VW-PW (Sizes 175-400) - Installation, Operation and Maintenance Instructions User Manual

Page 12

LAARS Heating Systems

Page 12

Heat

Flow

Pressure*

Water Temp

Exch.

Water

Rate

Drop

Rise

Model

Passes

Category

gpm

L/s

ft.

m

°

F

°

C

175

2

Soft

22

1.4

5.8

1.8

13

7

Normal

34

2.1

11.2

3.4

8

4

Hard

46

2.9

19.1

5.8

6

3

4

Soft

11

0.7

4.9

1.5

25

14

Normal

17

1.1

9.3

2.8

16

9

Hard

23

1.5

15.9

4.8

12

7

250

2

Soft

22

1.4

5.8

1.8

18

10

Normal

34

2.1

11.2

3.4

12

7

Hard

46

2.9

19.1

5.8

9

5

4

Soft

11

0.7

4.9

1.5

35

19

Normal

17

1.1

9.3

2.8

33

18

Hard

23

1.5

15.9

4.8

17

9

325

2

Soft

34

2.1

12.5

3.8

18

10

Normal

34

2.1

12.5

3.8

18

10

Hard

46

2.9

21.7

6.6

11

6

4

Soft

17

0.7

10.4

3.2

36

20

Normal

17

0.7

10.4

3.2

30

17

Hard

23

1.5

18.1

5.5

22

12

400

2

Soft

34

2.1

13.3

4.1

19

11

Normal

34

2.1

13.3

4.1

19

11

Hard

46

2.9

23.4

7.1

14

8

4

Soft

17

0.7

11.1

3.4

37

21

Normal

17

0.7

11.1

3.4

37

21

Hard

23

1.5

19.5

5.9

27

15

*Pressure drop includes head loss of heat exchanger and through 30 feet (9.1 m) of pipe and normal fittings when

heater is installed with storage tank. Pipe and fittings are assumed to be 1-1/2 inch (38 mm).

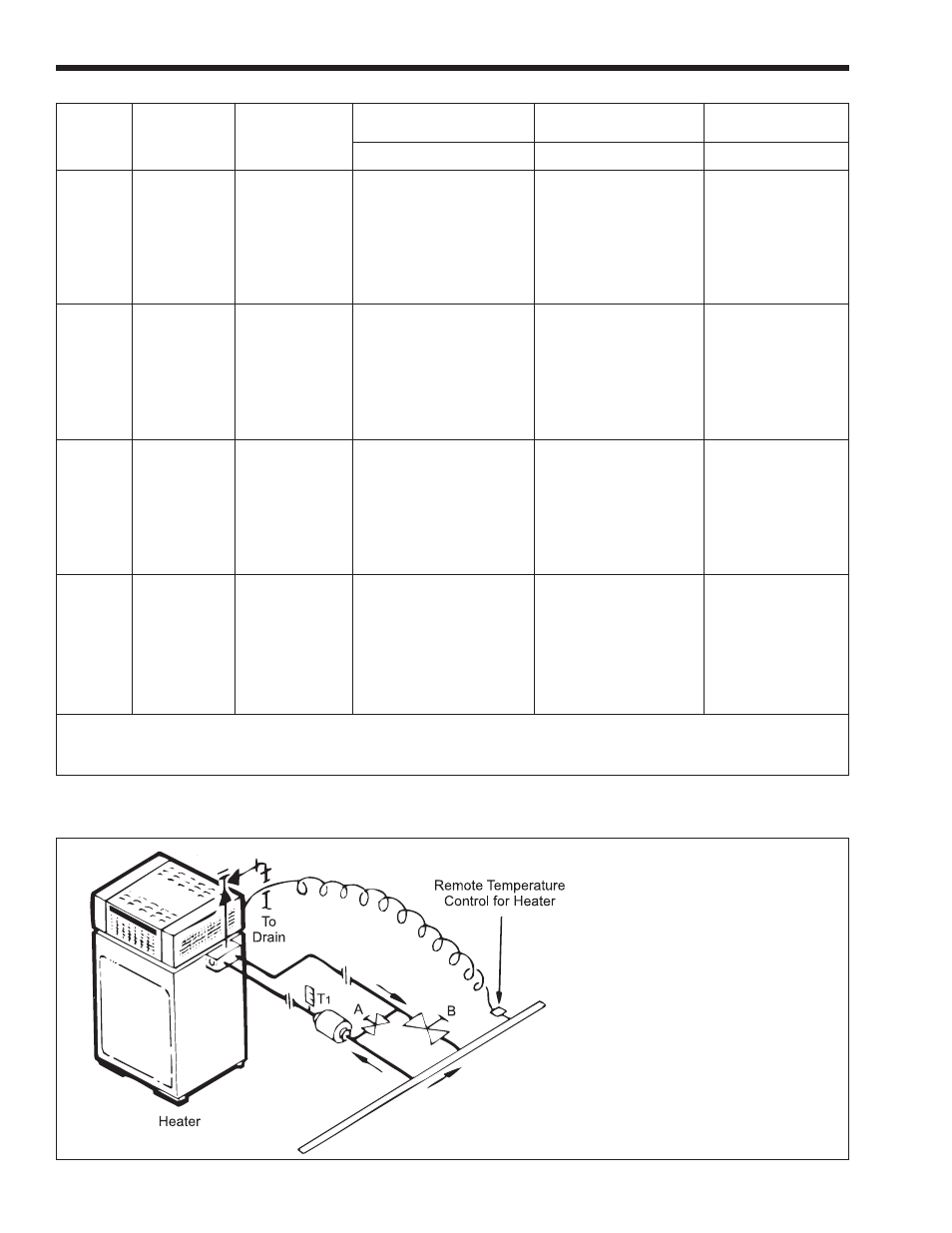

Main Circulating Loop

(With Own Pump)

Water Maintained

Less Than 110°F (43°C)

Adjustment Procedure

1.

Turn on heater and open gate

valves A and B.

2.

After 15 minutes, read T

1

.

3.

If T

1

is less than 110°F (43°C),

slowly close valve B until T

1

climbs to 110°F (43°C).

4.

If T

1

is greater than 110°F (43°C),

slowly close valve A until T

1

drops to 110°F (43°C).

5.

Check after 5 minutes

operation and make final

adjustments.

Figure 20. Cold water application.

Table 4. Pump Performance Requirements.