LAARS Mighty Therm VW-PW (Sizes 175-400) - Installation, Operation and Maintenance Instructions User Manual

Page 14

LAARS Heating Systems

Page 14

valve is directed to an open drain and protected

from freezing.

2.

Install a properly sized thermal expansion tank on

the cold water supply line.

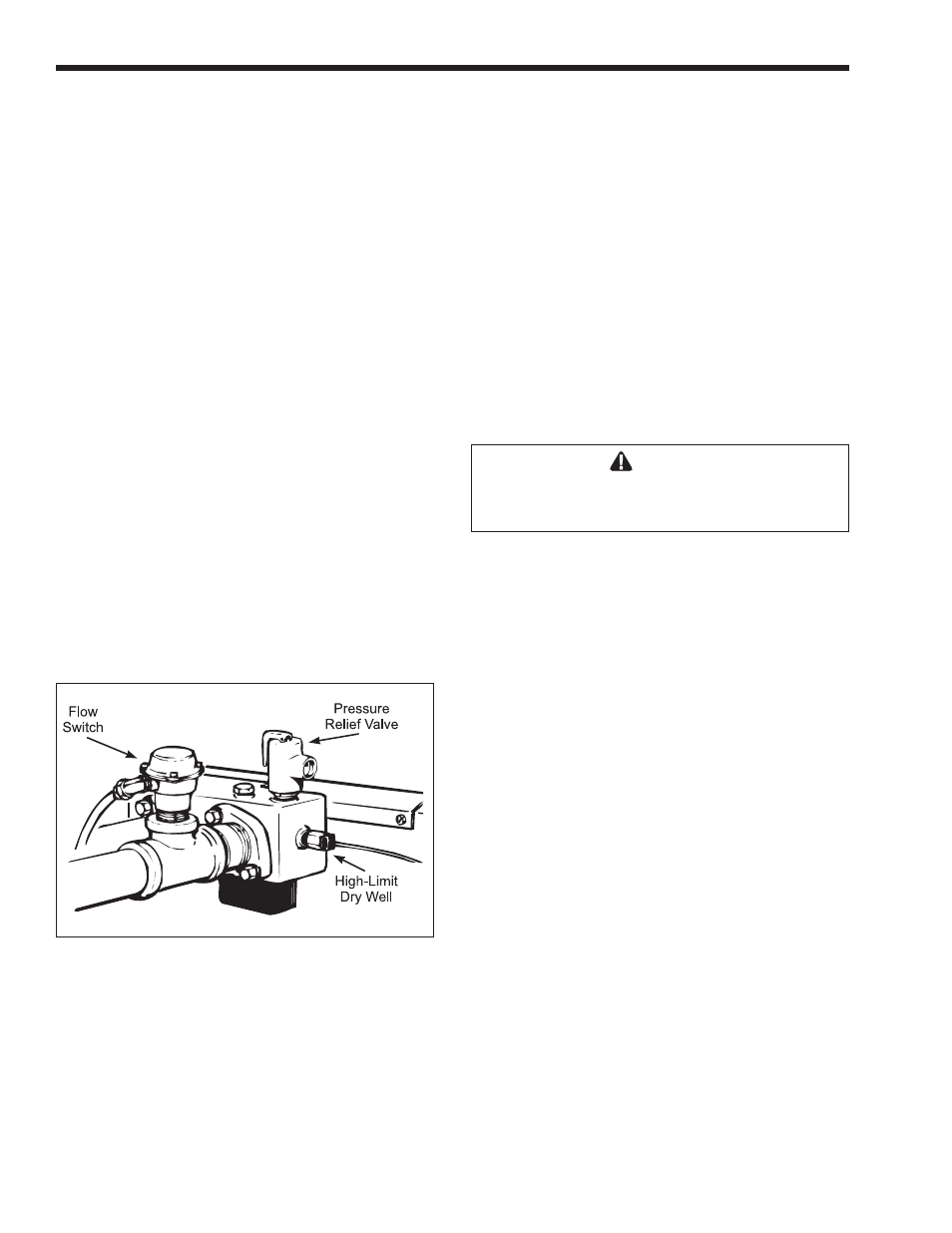

2.6.7 Pressure Relief Valve

The pressure relief valve must be installed in the

tapped opening provided in the boiler header with its

outlet piped to a drain or floor sink. Special attention

must be given to relief valve settings in installations

where the boiler is located on the ground floor of a tall

building, or where the operating temperature of the

boiler is above 210°F. In both instances, the static

pressure of the system is elevated, and could cause the

relief valve to leak. Where no special setting of the

relief valve is ordered, the factory will furnish a

125 psi setting.

WARNING

Hot water can scald! Hot water can produce

third degree burns in 6 seconds at 140°F (60°C) and

in 30 seconds at 130°F (54°C).

2.6.8 Water Pressure

Keep the water pressure in the system above

30 psi (207 kPa). If the system pressure drops below

30 psi (207 kPa), it could damage the heater through

lack of circulation. If for any reason, the water is

turned off temporarily, to service the equipment for

example, airlock could be a problem when the heater

is turned back on. To eliminate the airlock, open the

pressure relief valve (see Figure 23) and allow the air

to bleed out until water starts to flow. As soon as full

circulation is restored, the trapped air will be released

through the hot water faucets.

2.6.9 Pump Installation (Model VW)

1.

Install a properly sized pump to provide water

circulation between the heater and the storage tank.

2.

Size the pump to avoid an excessive temperature

rise (see Table 4), and to provide the correct flow

for prevailing water hardness conditions.

3.

Install the pump in a cool location. The life of the

pump can be shortened by exposure to excessive

heat. If the pump is equipped with a thermal

protection device, excessive heat may trip the

thermal switch. This could cause the pump to

shut down intermittently, resulting in rapid

scaling of the heat exchanger.

4.

If designed for floor mounting, install pump

securely on concrete block or pad at least

6 inches (152 mm) above floor level. This will

prevent flooding of the motor when the floor is

washed.

5.

Do not suspend floor mounted pumps from piping.

6.

Plumb piping to avoid putting strain on the pump

casing.

2.6.5 Pump Requirements

The VW heater does not have a factory installed

pump (see Table 4 for pump performance require-

ments). The PW heater does have a factory installed

pump which is for heater-to-tank circulation only.

VW and PW heaters are not designed for applica-

tions where the temperature of the water flowing

through the heater remains below the dew point, 110°F

(43°C).

If low inlet water temperatures are expected,

bypass plumbing as shown in Figure 20 should be used

to temper the incoming water.

The factory provided pump on the PW heaters,

and the pumps recommended for field installation on

VW heaters, are sized to provide proper circulation

through the heater, and through the heater-to-tank

circulation loop (see Figures 20 through 22).

If the heater-to-tank circulation loop does not

contain more than 6 elbows or 30 feet (9.1 m) of pipe,

the minimum pipe fitting should be 1-1/2 inches (38

mm). If the loop does contain more than 6 elbows or

30 feet (9.1 m) of pipe, the minimum size should be

2 inches (51 mm).

2.6.6 Pressure Buildup in Water System

The water utility supply meter may contain a

check valve, back flow preventer, or water pressure

reducing valve that will create a closed water supply

system. Contact the water supplier or local plumbing

inspector on how to control this situation.

Figure 23. Pressure relief valve.

During the heating cycle of the heater, the water

expands creating a pressure buildup in the water

system. The pressure relief valve may discharge hot

water under these conditions, causing a loss/waste of

energy and a buildup of lime on the relief valve seat.

NOTE: Do not plug the relief valve.

There are two methods to prevent the relief valve

from discharging hot water in a closed water system:

1.

Install a pressure relief valve on the cold water

supply line. Make sure that the discharge of this