Carrier 38YCX User Manual

Page 3

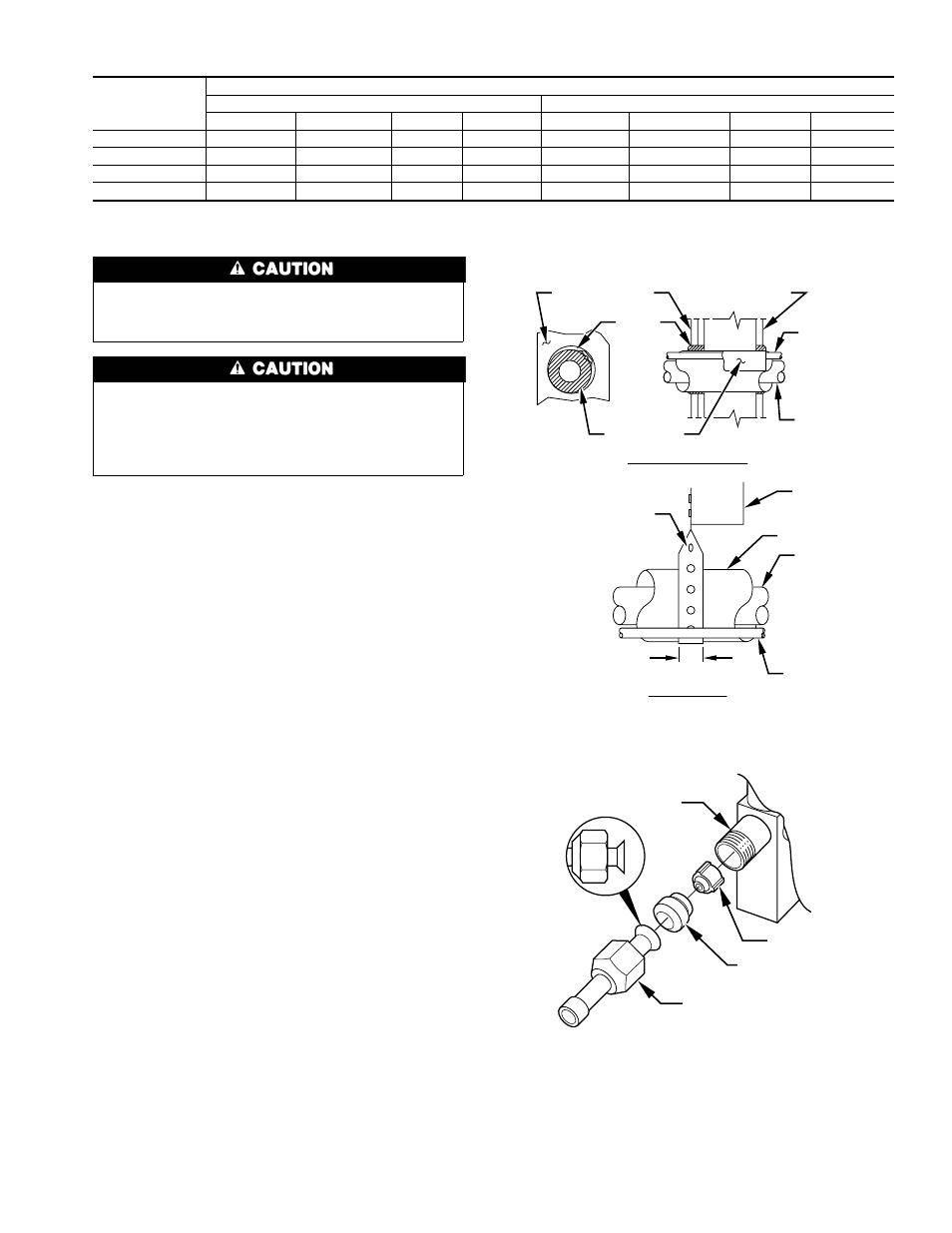

To prevent compressor damage DO NOT bury more than 36

in. of refrigerant tubing. If ANY tubing is buried, provide 6

in. vertical rise at service valve.

To prevent damage to unit or service valves observe the

following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 50 ft (15.24m),

consult Long-Line Application Guideline which is available from

your local distributor.

NOTE:

In some cases noise in the living area has been traced to

gas pulsations from improper installation of equipment.

INSTALLATION RECOMMENDATIONS

1. Locate unit away from windows.

2. Ensure that vapor and liquid tube diameters are appropriate to

capacity of unit. (See Table 1.)

3. Run refrigerant tubes as directly as possible by avoiding

unnecessary turns and bends.

4. Leave some slack between structure and unit to absorb

vibration.

5. When passing refrigerant tubes through the wall, seal opening

with RTV or other pliable silicon-based caulk. (See Fig. 4.)

6. Avoid direct tubing contact with water pipes, ductwork, floor

joists, wall studs, floors, and walls.

7. Do not suspend refrigerant tubing from joists and studs with a

rigid wire or strap which comes in direct contact with tubing.

(See Fig. 4.)

8. Ensure that tubing insulation is pliable and completely sur-

rounds vapor tube.

9. When necessary, use hangar straps which are 1 in. (25mm)

wide and conform to shape of tubing insulation. (See Fig. 4.)

10. Isolate hangar straps from insulation by using metal sleeves

bent to conform to shape of insulation.

If refrigerant tubes or indoor coil is exposed to atmosphere, it must

be evacuated to 500 microns to eliminate contamination and

moisture in the system.

OUTDOOR UNIT CONNECTED TO FACTORY-APPROVED

INDOOR UNIT — Outdoor unit contains correct system refriger-

ant charge for operation with indoor unit of same size when

connected by 15 ft (4.55m) of field-supplied or factory-accessory

tubing. Check refrigerant charge for maximum efficiency.

Table 1—Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters

UNIT SIZE

LIQUID

VAPOR

Connection Dia.

Tube Dia.

Connection DIia.

Vapor Dia.

In.

mm

In.

mm

In.

mm

In.

mm

024

3/8

9.53

3/8

9.53

5/8

15.88

5/8

15.88

036

3/8

9.53

3/8

9.53

3/4

19.05

3/4

19.05

048

3/8

9.53

3/8

9.53

7/8

22.23

7/8

22.23

060

3/8

9.53

3/8

9.53

7/8

22.23

1-1/8

28.58

NOTES: 1. Tube diameters are for lengths up to 50 ft (15.24m). For tubing lengths greater than 50 ft (15.24m), consult Long-Line Application Guideline.

2. Do not apply capillary tube indoor coils to these units.

Fig. 4—Piping Installation

A94330

INSULATION

VAPOR TUBE

LIQUID TUBE

OUTDOOR WALL

INDOOR WALL

LIQUID TUBE

VAPOR TUBE

INSULATION

CAULK

Avoid contact between tubing and structure.

NOTE:

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

JOIST

1

″

MIN

(25 mm)

SUSPENSION

Fig. 5—Service Valve with Sweat Adapter Tube

A94029

PISTON BODY

PISTON

PISTON RETAINER

SWEAT/FLARE ADAPTER

3