Intek RheoVac SENTRY User Manual

Page 4

- 2 -

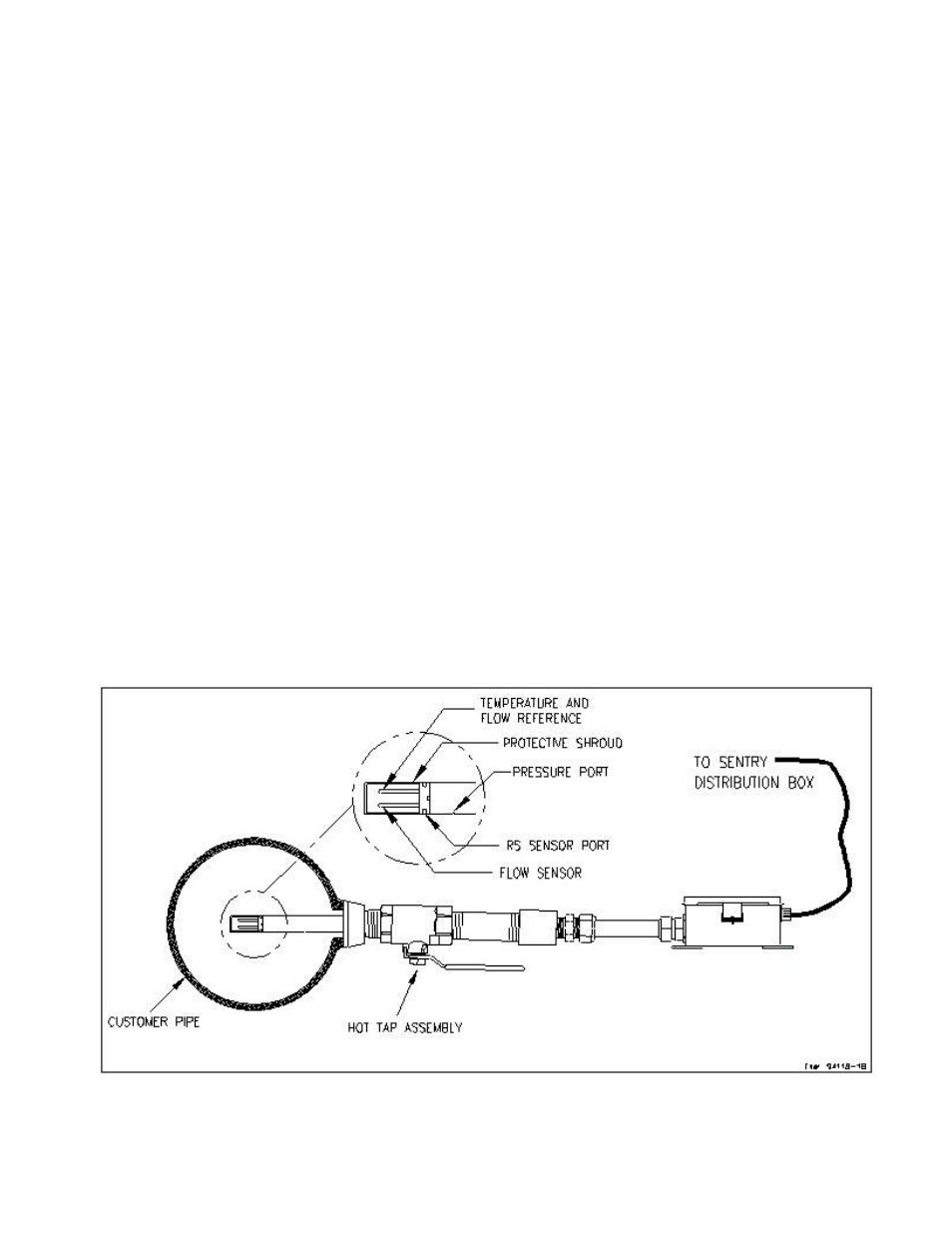

Figure 1 RheoVac Probe Sensor Monitor

1.3 USES

The RheoVac SENTRY System can be used for a multitude of performance related subjects, such as:

•

Continuous air in-leak monitoring

•

Vacuum pump performance testing

•

Operating with zero excess back pressure

•

Load dependent air in-leak isolation

•

Optimizing condenser performance

•

Scheduled preventive maintenance

•

Leak detection during hogging operation

•

Minimizing heat rate

•

Optimizing condensate/water chemistry

•

Understanding condenser performance

1.4 PRINCIPLE OF OPERATION

The RheoVac technology utilizes multiple primary sensors configured in a single probe head and an

electronic signal conditioner and digital signal processor unit. The sensing probe is installed in the

vacuum line between the condenser and the exhauster. The RheoVac instrument makes no assumptions

about the dynamic condenser and vacuum line environment. The sensor head employs the patented

Rheotherm

®

technology to provide an accurate flow measurement. Additionally, temperature, pressure

and water vapor relative saturation measurements are made using a high accuracy platinum resistance

temperature detector (RTD), a strain gauge pressure sensor and a specially configured and calibrated

water vapor saturation sensor. The principal features of the RheoVac sensor are shown in Figure 1.