Intek RheoVac SENTRY User Manual

Page 16

- 14 -

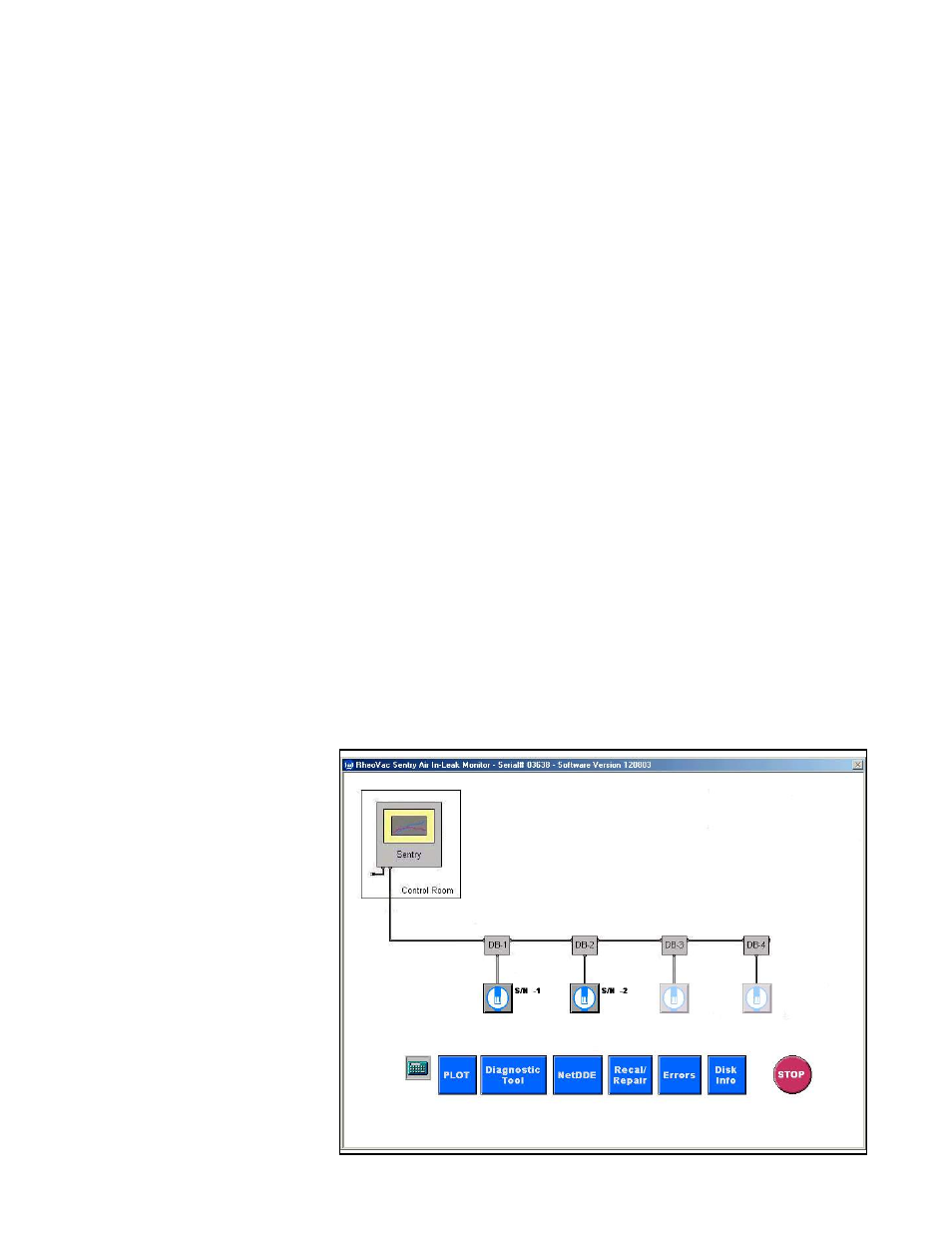

Figure 8 - System Diagram

a given probe remain unchanged. To custom label the SENTRY screen with actual probe locations, you

will need to plug a PS-2 style computer keyboard into the back of the SENTRY touchscreen. After

plugging in the keyboard, reboot the SENTRY (cycle power off, then on). Press the button labeled

‘Recal/Repair’ on the RheoVac SENTRY front panel. When the Recal/Repair options panel appears,

press the button labeled ‘Probe Labels.’ The Probe Location/Information panel will appear. A space

is provided for an eight-character description to be added to each probe label (this eight-character limit

is set due to space constraints on the SENTRY front panel). After you have input your custom labels,

press the Save button. Changes will take effect when you exit back to the front panel.

Complete evaluation of a typical condenser and exhauster system is accomplished using a multiple probe

RheoVac SENTRY configuration. A multi-probe installation provides centralized data collection for all

flow paths in the air extraction system, which will aid in locating leaks and identifying exhauster

malfunction. Each SENTRY CPU is capable of supporting up to twelve RheoVac probes. Therefore, it

is possible that the configuration chosen for your plant may have the SENTRY CPU monitoring probes

installed on more than one generating unit. Accordingly, it is imperative that the serial number of the

probes and their installed locations, as shown on the original factory configuration, be clearly retained

and readily accessible.

3.4 CPU TOUCH SCREEN

The RheoVac SENTRY System CPU touch screen provides operator access, interface and control of the

components of the system. This section discusses the data and diagnostic information available to

engineers and operators via this touch screen.

Main Screen — System Diagram

The CPU main screen will show a general layout of your SENTRY System. The drawing here is a

generic example. Touching a probe “button” or icon brings up the display screen associated with that

probe. The light at the lower left of the screen indicates communication status — when data is

transmitting, the light flashes red; when no data is being transmitted, the light is a steady green. At the

bottom of the screen are the

“buttons” that provide

access to the next level of

data detail. These buttons

access the Plot, Diagnostic

T o o l , D i s k I n f o ,

Recal/Repair, and Errors

f u n c t i o n s .

T h e

Recal/Repair function is

not used in the field except

as described above.

The STOP button should

only be used to stop

program

execution and all

communications with the

probes. This is necessary

only for factory personnel to

perform software updates

and system service.