23 - table iii - trouble shooting guide – Intek RheoVac SENTRY User Manual

Page 25

- 23 -

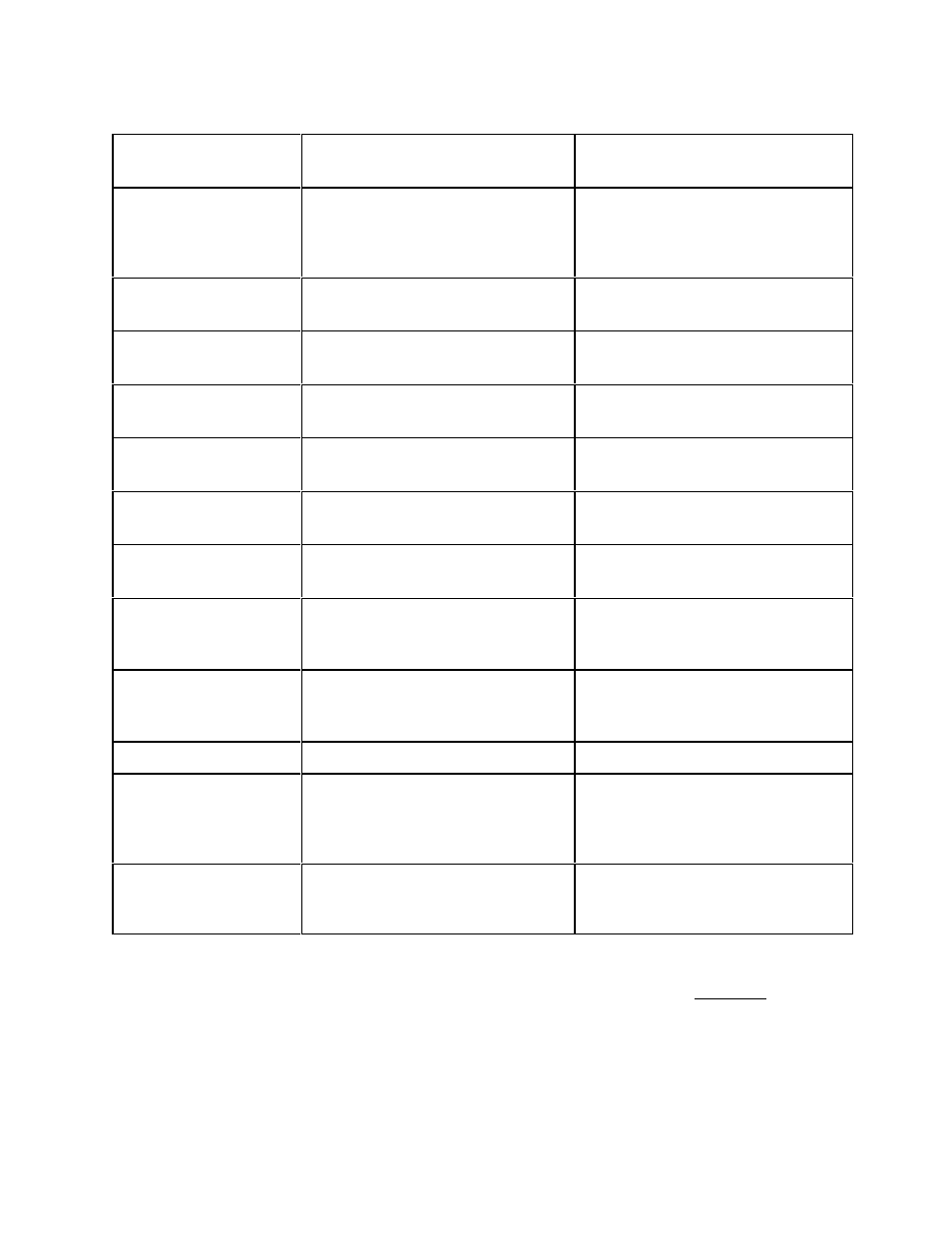

Table III - Trouble Shooting Guide

Error Log

Description/Symptom

Probable Cause

Action

Communications not

being received from

probe(s)

1.

Improper cable hookup

2.

Blown main fuse

3.

Failed RS-485 circu it

4.

Damaged flow sensor

1.

Verify cable hookup is correct

2.

Check cable connections

3.

Contact factory

Invalid checksum received

from probe(s)

1.

Failed RS-485 communications

component

1.

Contact factory

Invalid checksum received

from probe(s)

1.

Failed RS-485 communications

component

1.

Contact factory

Relative saturation sensor

power 'O FF''

1.

Failed sensor or other electronic

component

1.

Contact factory

Relative saturation sensor

heater 'OF F''

1.

Failed electronic component

1.

Contact factory

Flow sensor heater

‘OFF'’

1.

Blown heater fuse (F3)

2.

Failed electronic component

1.

Replace heater fuse

2.

Contact factory

Pressure sensor heater

'OFF'’

1.

Blown heater fuse (F2)

2.

Failed electronic component

1.

Replace heater fuse, contact factory

2.

Contact factory

Temperature above

specified maximum limit

1.

Temperature above 210/F

2.

Possible sensor dam age

1.

Remove sensor from flow stream

and contact factory

2.

Contact factory

Wet probe

1.

This usually indicates a condenser

design or operation problem that

requires corrective action.

1.

Contact factory

RS sensor problem

1.

RS sensor or circuit has failed.

1.

Contact factory

Mass flow output

saturates high, will not

respond to flow changes

1.

Flow rate is not within range of

calibration

2.

Blown heater fuse

3.

Failed electronic component

1.

Contact factory about re-ranging

instrument

2.

Replace fuse

3.

Contact factory

Mass flow output

saturates low, will not

respond to flow changes

1.

Flow rate is not within range of

calibration

2.

Failed electronic component

1.

Contact factory about re-ranging

instrument

2.

Contact factory

If the RheoVac SENTRY is operating without error indications but output readings from one or more

probes are questionable, please send to Intek by telefax or e-mail the following plant data: turbine back

pressure, hot well temperature, load, and inlet and outlet circulation water temperatures, along with a

minimum of 4 hours of concurrent data from all RheoVac probes on that generating unit. You may also

contact the factory to transmit RheoVac SENTRY probe data via modem to the factory for analysis and

problem resolution.