Engine installation – Great Planes Super Sportster 40 ARF - GPMA1040 User Manual

Page 11

❏

1. Locate the 19-5/8" [498mm] throttle pushrod wire. Attach

the “Z-bend” into the inside hole of the carburetor control

arm. Make sure the “Z-bend” does not interfere with any

parts of the engine.

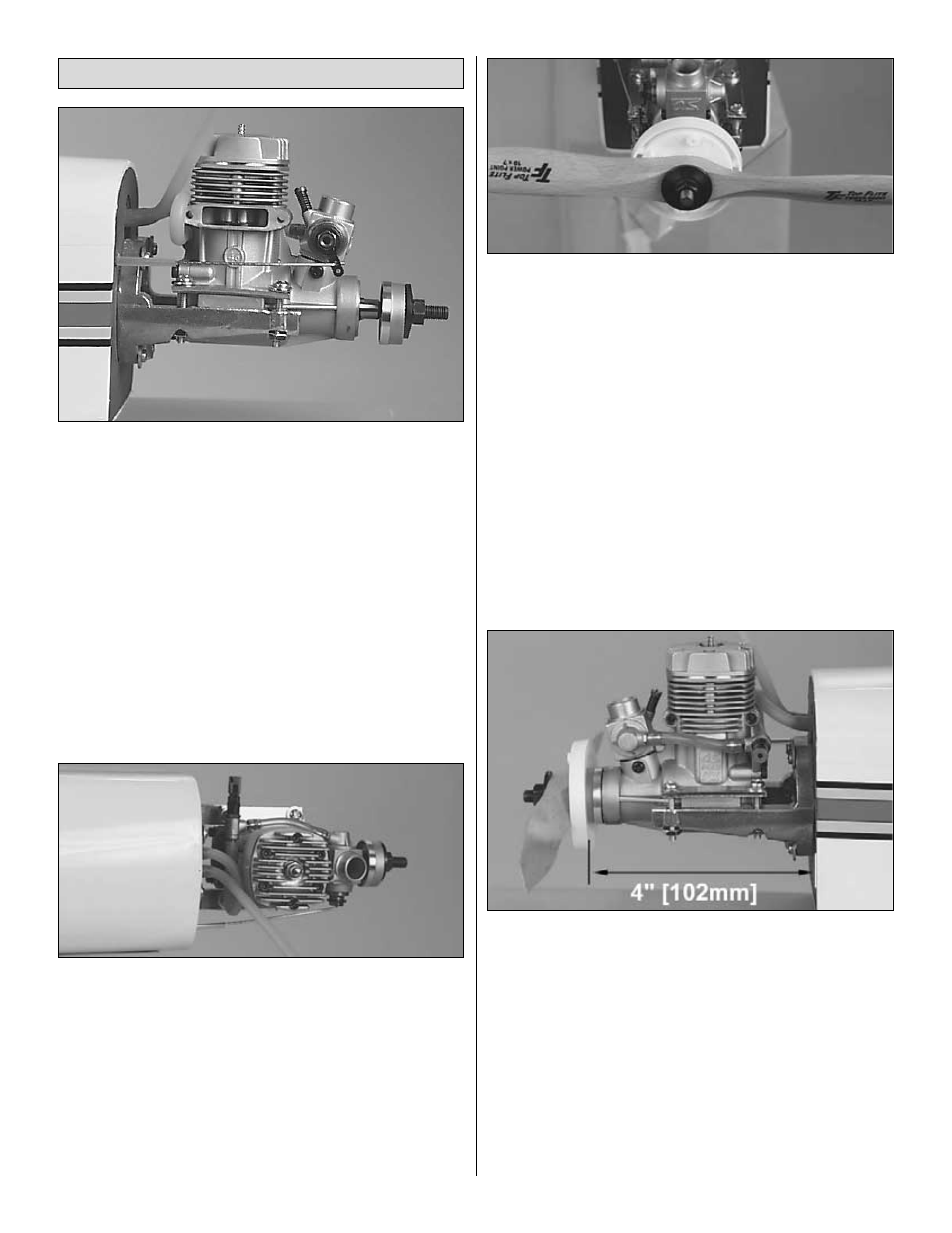

The engine in your aircraft is mounted slightly different from

those in most R/C aircraft. This is done to allow the use of

many different types of engines. It also allows a “no-drill”

approach to ease the installation. Read through the

procedure and understand all the steps before actually

performing them.

❏

2. The engine is “sandwiched” between the engine mount

and the engine mount plates. Slide the throttle pushrod into

the pushrod housing and rest the engine on the mount. Slide

a #6 washer onto a 6-32 x 1" machine screw. Repeat this

process for all four screws and washers. Pass the screws

through the engine mount plates. The screws then go

through the mount, passing in front of and behind the engine

mounting flange. The plates will be resting on the top of the

engine’s mounting flanges. The 6-32 nuts are then placed

into the recesses on the bottom of the engine mount. Start

the screws, but do not tighten them at this time. We still

need to align the engine!

❏

3. Install the spinner backplate, propeller, propeller washer

and the propeller nut onto the engine. Turn the propeller

counterclockwise until it is against the smallest pins on the

backplate. Keep the propeller horizontal when the engine is

against its compression (the point at which you feel

resistance when you turn the crankshaft counterclockwise).

This is a good habit to get into when installing propellers

onto model airplanes. If the engine quits during flight, the

propeller will stop horizontally, therefore reducing the

chance of propeller breakage if you are forced to land on

rough terrain. Use an adjustable wrench (not a pliers) to

securely tighten the propeller nut.

❏

4. Measure the distance from the back of the spinner backplate

to the firewall. It should be 4-1/8" [105mm] on both sides.

Adjust the engine if needed and tighten the screws evenly to

secure the engine to the mount. Use thread-lock on the nuts

to prevent loosening.

❏

5. Attach the fuel line (with the clunk) to the carburetor.

Engine Installation

11