Great Planes Giant Revolver ARF - GPMA1425 User Manual

Page 7

7

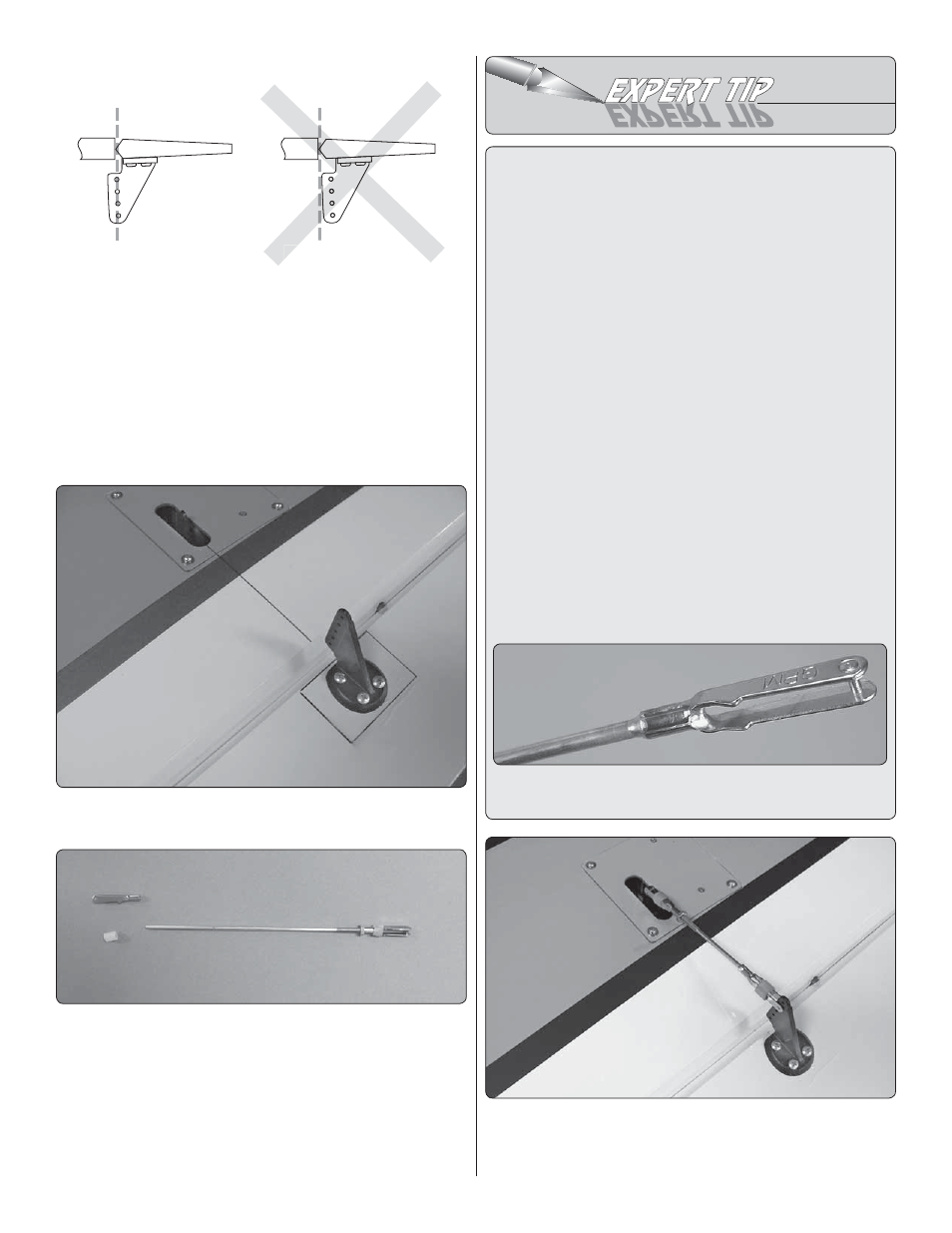

Hinge Line

Hinge Line

CORRECT

INCORRECT

Hi

❏ ❏

8. The aileron has a plywood control horn mounting

plate built into it. Place a control horn onto the plate in line

with the servo arm. Drill a 3/32" [2.4mm] hole through each

of the four mounting holes, into the plywood plate. DO NOT

DRILL THROUGH THE OPPOSITE SIDE OF THE AILERON!

❏ ❏

9. Install and then remove a #4 x 5/8" sheet metal screw

into the four holes you drilled. Apply a couple of drops of thin

CA glue into the holes to harden the threads. Allow the glue

to harden.

❏ ❏

10. Secure the horn to the aileron with four #4 x 5/8"

sheet metal screws.

❏ ❏

11. Locate a 4-40 x 5-3/4" [146mm] threaded pushrod

wire, 4-40 nut, 4-40 threaded clevis, 4-40 solder clevis and

two silicone clevis keepers. Assemble the pushrod as shown.

❏ ❏

12. Install the pushrod assembly to the servo arm. Install

the 4-40 solder clevis into the hole second from the end of the

control horn. Center the aileron and make a mark on the wire

where it will need to be cut. Remove the pushrod assembly

and the solder clevis. Cut the wire on the mark you made.

HOW TO SOLDER

1. Use denatured alcohol or other solvent to thoroughly

clean the pushrod. Roughen the end of the pushrod with

coarse sandpaper where it is to be soldered.

2. Apply a few drops of soldering fl ux to the end of the

pushrod, and then use a soldering iron or a torch to heat

it. “Tin” the heated area with silver solder by applying the

solder to the end. The heat of the pushrod should melt the

solder – not the fl ame of the torch or soldering iron – thus

allowing the solder to fl ow. The end of the wire should be

coated with solder all the way around.

3. Place the clevis on the end of the pushrod. Add another

drop of fl ux, then heat and add solder. The same as

before, the heat of the parts being soldered should melt

the solder, thus allowing it to fl ow. Allow the joint to cool

naturally without being disturbed. Avoid excess blobs, but

make certain the joint is thoroughly soldered. The solder

should be shiny, not rough. If necessary, reheat the joint

and allow to cool.

4. Immediately after the solder has solidifi ed, but while it

is still hot, use a cloth to quickly wipe off the fl ux before

it hardens. Important: After the joint cools, coat the joint

with oil to prevent rust. Note: Do not use the acid fl ux that

comes with silver solder for electrical soldering.

This is what a properly soldered clevis looks like –

shiny solder with good flow, no blobs and flux removed.

❏ ❏

13. Using the instructions in the Expert Tip, “How To

Solder”, install the 4-40 solder clevis onto the end of the

pushrod wire soldering the clevis to the wire. After the solder