Install the power system, Glow engine installation – Great Planes F1 Rocket Evo GP/EP ARF - GPMA1030 User Manual

Page 14

14

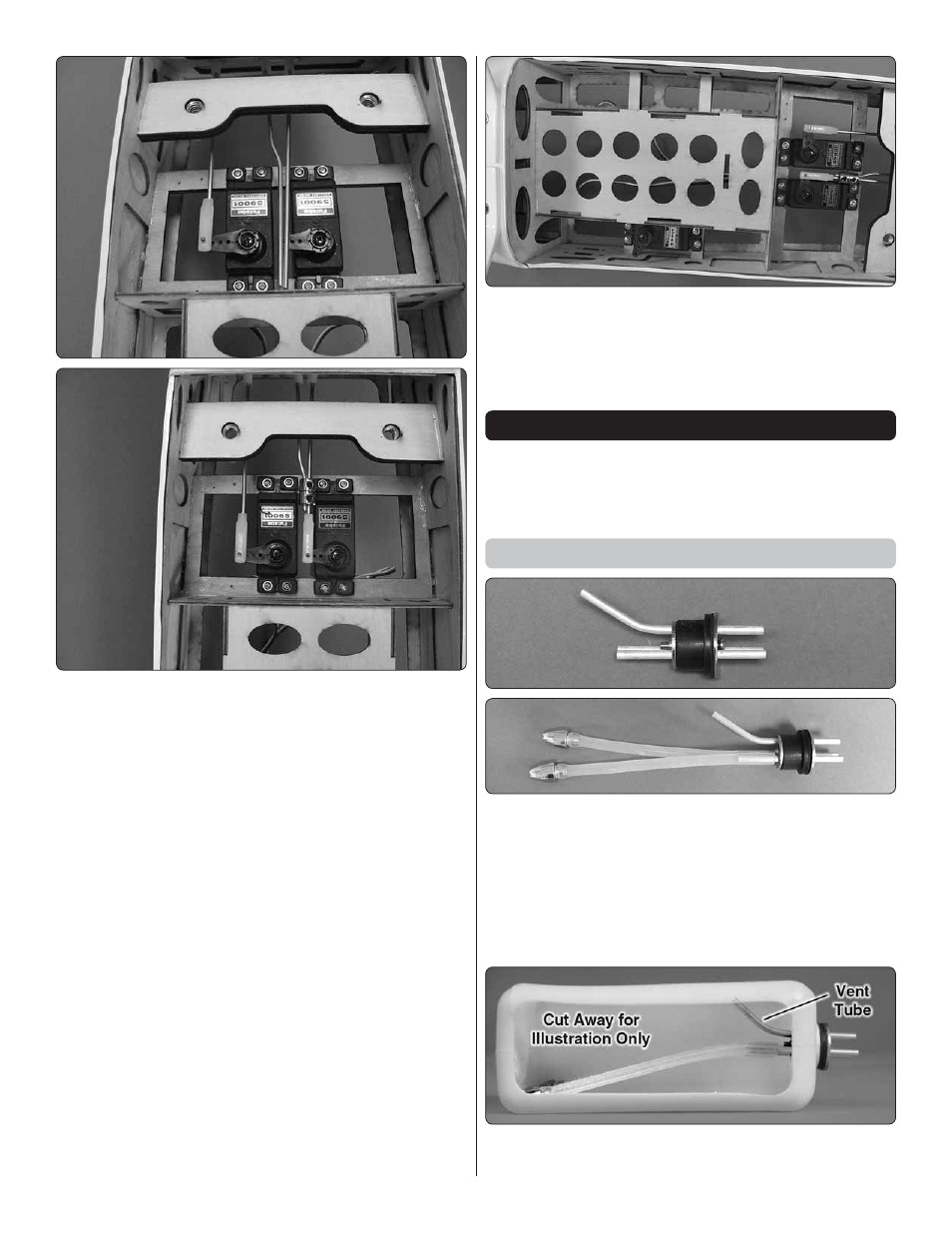

❏

6. Bend one of the elevator pushrod wires as shown. Align

both the left and right elevator halves. Apply a couple of drops

of thread locker onto two 4-40 x 1/8" [3.2mm] set screws

and then install them into two 5/32" wheel collars. Slide the

wheel collars onto both of the wires. On the wire you made

the bends, make a mark where the outer wheel collar rests.

Cut off the excess wire. Tighten the set screws against the

pushrod wires.

❏

7. As you did with the rudder, make a mark on the remaining

elevator pushrod wire where it aligns with the outer hole in

the servo arm. Make a 90 degree bend at the mark and cut

off the excess pushrod 1/4" [6mm] beyond the bend. Secure

the pushrod to the servo arm with a nylon FasLink. Make any

adjustments necessary to the nylon clevis so that the elevator

is properly centered.

If you will be installing an electric motor skip the next

step and move ahead to “Installing the Electric Motor

on page 17.

❏

8. Though the engine has not been installed yet, determine

which side of the fuselage to install the throttle servo based

on the location of the throttle arm on the engine. Install the

servo as shown using the hardware that came with the servo.

Drill a 5/64" hole in the outer servo arm hole.

INSTALL THE POWER SYSTEM

The F-1 Rocket ARF is designed to be fl own with a .46-.55

two-stroke glow engine, .70 four-stroke glow engine, or an

out-runner brushless motor. If you plan to install a brushless

motor, skip ahead to page 17, “Install the Electric Motor”.

Glow Engine Installation

❏

1. The fuel tank will be assembled as a three line system

having a vent line, carb line, and fi ll line. Puncture the top

of the stopper above the sealed off fuel tube hole. With the

tubes installed in the stopper, fi t the stopper plates loosely in

place with the 3x25mm phillips screw to hold the assembly

together. The fi ll and carb tubes should extend out 1/2" [13mm]

beyond the stopper and the vent line should be bent upwards

and left uncut.

❏

2. Fit the stopper assembly into the tank with the vent line

pointing toward the top of the tank, but not touching. The fuel